Advanced Full Set of Silicone Gasket Manufacturing Equipment For Your Business

As a professional silicone gasket manufacturer and supplier, Baiwe can provide one-stop service for your custom silicone rubber gasket, from the mold making to the production of silicone gaskets, we can customize various types of silicone gaskets for you, food-grade silicone gasket, industrial-grade silicone gasket, and medical-grade silicone gasket.

Our production equipment is fully equipped, and there are different molding methods for you to choose silicone compression molding, liquid silicone injection molding, silicone transfer molding. The specific molding method should be determined according to your application requirements and budget of silicone gasket.

We can accept small orders of the silicone rubber gasket, we will provide you with the best service. Send me your request now and we will be your reliable silicone gasket manufacturer and supplier.

Custom made silicone gasket for medical device

High-quality food grade silicone gasket

We can custom made all kinds of silicone gasket for electronics

Medical grade liquid silicone gasket

High quality silicone gasket with different sizes and colors

Custom made silicone gasket with sticker

Baiwe:We Will be Your Trustworthy Silicone Gasket Maker

If you are looking for a silicone rubber gasket manufacturer, you are in right place. we can custom-made all types of silicone gasket for you. Such as silicone u channel gasket, u shaped rubber gasket,c shaped silicone rubber gasket, etc. And there are many different kinds of durometer for your choice, we have 30 to 80 durometer can meet most of silicone gasket requirement. If you have a special demand for your silicone gasket project, we also can custom made it for you.

Our own high-precision silicone mold-making technology and experienced team can offer you the smallest flashed and parting lines, it can make sure you will get the best quality of silicone gasket ring.

The small quantity of silicone gaskets also can be acceptable. You can choose us as your silicone gasket manufacturer and supplier for your next order.

- Manufacturing

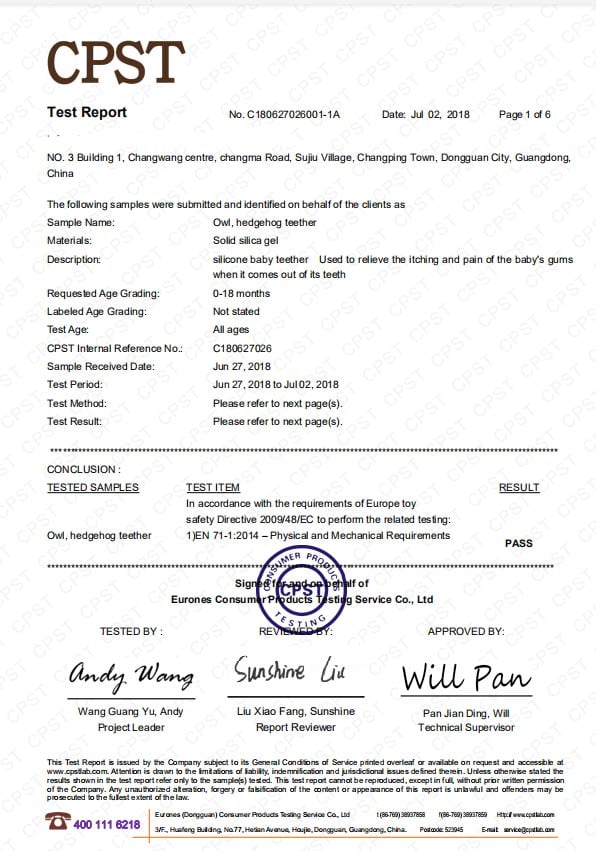

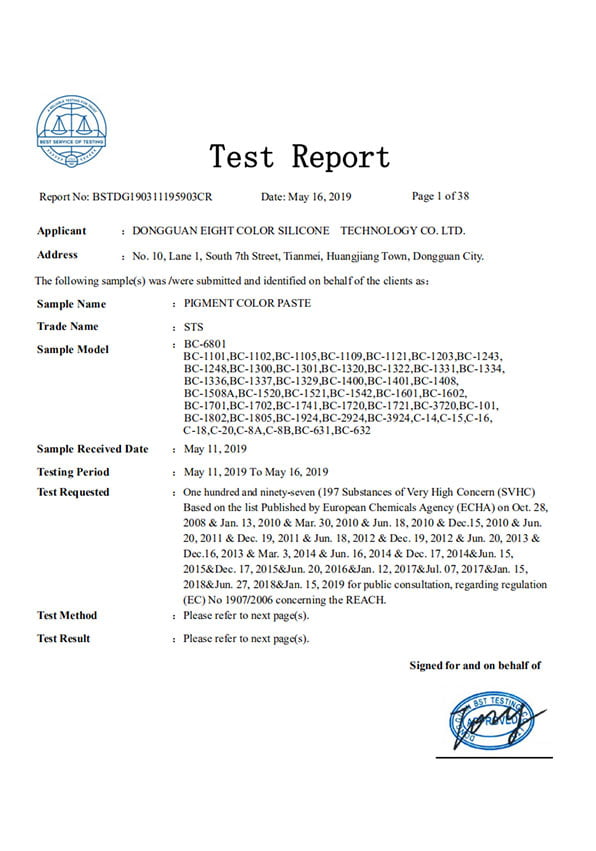

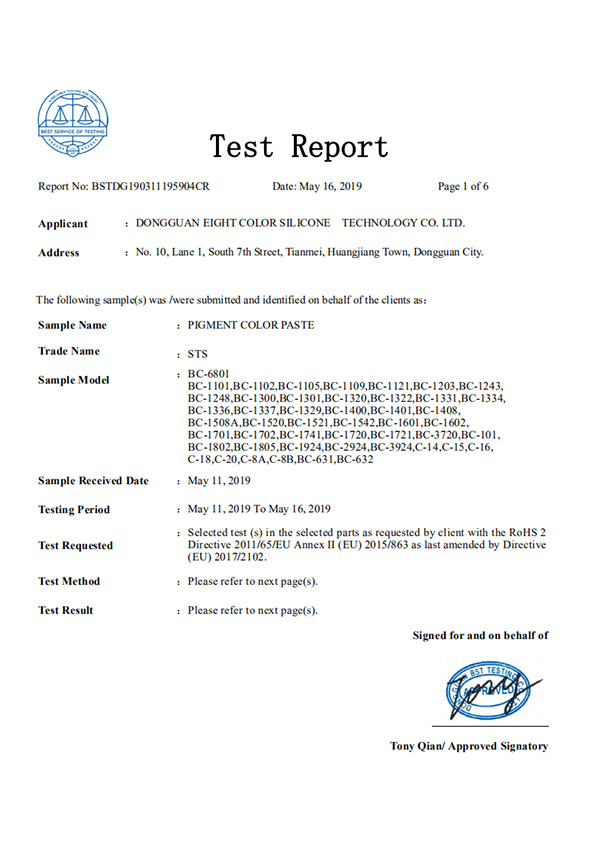

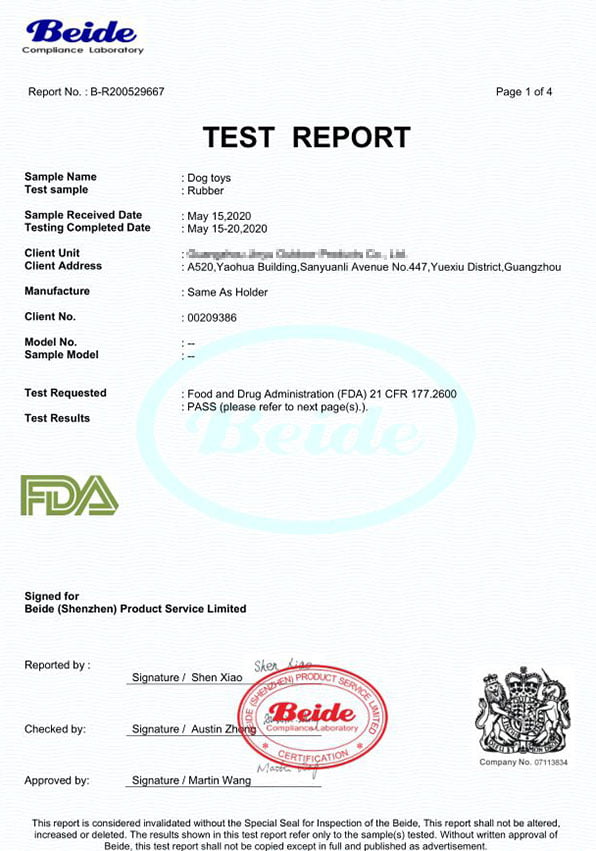

- Certifications

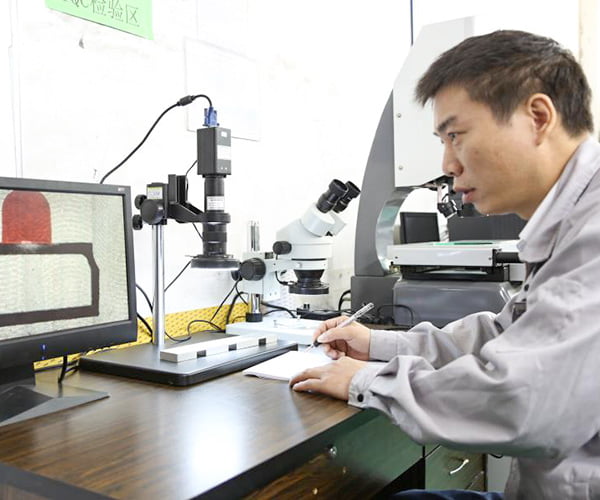

- Top Quality Control

![]()

We Also Can Custom Made Other Silicone Parts For You

We are a professional silicone parts manufacturer with a full set of production equipment, including a CNC molding plant, different molding processes, for example, silicone compression molding, LSR injection molding, silicone overmolding, and silicone transfer molding. Your all kinds of silicone products can be custom made in our factory.

Send us your specific requirement right now, we will get back to you with our best quote soon!

Silicone Gasket – Ultimate FAQs Guide

Do you have queries about silicone gaskets and its manufacturing? We have made it easier for you by making an ultimate FAQ Guide about silicone gaskets. It has answers to almost every question that can pop up in your mind. Let’s get started.

- What’s Is a Silicone Gasket?

- What Are The Applications Of Silicon Gasket?

- What Are Some Of The Utilized Benefits Of Silicone Gasket?

- How Long Will Silicone Gaskets Last?

- How Are Silicone Gaskets Made?

- Does Silicone Make A Good Gasket?

- What Is The Difference Between Gasket Sealant AndGasket Maker?

- Do You Need Silicone For Oil Pan Gasket?

- Why Is Silicon A Preferred Material For Gasket?

- What Are Die Cut Silicone Gaskets?

- What Are Different Silicon Rubber Grades Available For Gasket Manufacturing?

- What Are Molded Silicone Gaskets?

- What Are Conductive Silicone Gaskets?

- What Are Food Grade Silicone Gaskets?

- Where Are Fluorosilicone Gaskets Used And How Are They Manufactured?

- Can I Get Customized Size Silicone Gaskets?

- How To Choose The Best Silicone Gasket Manufacturer From China?

- Do Chinese Manufacturers Produce Good Quality Silicon Gasket?

- How Much Time Is Needed To Deliver A Batch Of Silicon Gasket To My Country?

1. What Is Silicone Gasket?

The literal meaning of gasket is seal. Gaskets are a seal between two mating surfaces. A typical gasket is made of two static seals that latch two parts together. None of the two surfaces is a moving surface.

Gaskets have a lot of significance from a functional point of view. They can be used for noise reduction, temperature resistance, to prevent contamination, or in packaging as well.

But commonly, it is used in packaging as a covering or sheet to prevent leakage.

These gaskets can be made with any material i.e. rubber, paper, metal, silicone, or plastic. And a gasket that is made up of silicone material is known as a silicone gasket.

Nowadays, silicone gaskets have great functional importance in various industries. It has various sizes and shapes.

![]()

- What Are The Applications Of Silicon Gasket?

Silicone gaskets have been used commercially at various levels. So it has a vast set of applications. A few of them are:

- Medical

As mentioned previously that silicone gaskets are used to prevent contamination for hygiene purposes, it plays a great role in the medical field.

Silicone gaskets are variously used in catheters and tubes. IV bags and infusion devices also need a gasket. Moreover, many medical devices require a seal, which is accompanied by silicone gaskets.

- Automotive

In automotive industries, silicone gaskets fulfill the need for anti-vibration and sealing. O-ring seals are used in the radiators of automobiles to prevent leakage.

Moreover, it serves as an anti vibrator by saturating the vibration produced by engines of automobiles. Similarly, it is used in buses and trains.

- Aerospace

Similar to the automotive industry, silicone gaskets are used in the parts of aerospace to prevent vibration and noise.

Moreover, it is used to control extreme environments at extremely high altitudes in airplanes. Space shuttles and board equipment also use silicone gaskets to not only resist temperature but ozone and UV.

- Doors and windows

Today, HVAC systems are installed in houses to maintain indoor temperatures. For this purpose, the windows and doors require a seal. That is often accomplished by silicone gaskets.

With the advancement of the world, we all need a peaceful environment at home with no noise. This, too, is fulfilled by silicone gaskets. They are inserted in the doors and windows for noise reduction.

- Food packaging

To protect the food from contamination, they are often sealed with silicone gaskets. They are specially used in the packaging of beverages to prevent leakage.

Fresh vegetables, fruits, and raw meat are also saved from high temperatures by sealing them with silicone gaskets. Even distilled water tanks are packed with gaskets.

![]()

2. What Are Some Of The Utilized Benefits Of Silicone Gasket?

The vast use of silicone gaskets at the industrial level verifies that it has a ton of benefits. Here are a few of them.

- Hygiene purpose

As the world is advancing, people are more towards cleanliness and safety of themselves. They need packaged food that is safe and healthy. So they can stock it for a long time without contamination.

Moreover, they now desire organic and natural food without preservatives. And Silicon gasket play an important role in fulfillment of this purpose.

- Prevention of infection

In the medical field, silicone gaskets do their job by preventing the spread of infection. They seal the equipment properly with gaskets. So that there are no chances of germs entering.

- Prevention of leakage

Silicone gaskets seal beverages in a way that there is no chance of leakage anymore. Moreover, they are water repellent and provide an airtight seal.

So installed in water bottles and carbonated beverages. In the same way, they prevent oil leakage in the motor vehicle’s engine.

- Temperature resistant

Silicone gaskets are known to resist extremely high and extremely low temperatures. A standard silicone gasket can even withstand -40 degrees Celsius and 240 degrees Celsius temperature.

They maintain the indoor environment while protecting it from harsh conditions. That is why silicone gaskets are now being used in doors and windows too.

They are also useful in substances that require a specific temperature to be maintained in packaged food and beverages.

- Economical

Silicone gaskets are inexpensive and have a longer shelf-life. They are durable. Once installed, they require minimal maintenance. So it appears to be a profitable investment.

3. How Long Will Silicone Gasket Last?

Silicone gaskets are highly durable and require less maintenance. They are said to have the highest shelf life of 20 years while that of natural rubber is 5 years.

So a typical silicone gasket can last for up to twenty years. However, factors like temperature, humidity, and UV can disrupt its shelf life.

Still, silicone is the material that can withstand such factors competently. Otherwise, natural rubber can generate rapidly when exposed to harsh environments.

- How Are Silicone Gaskets Made?

Silicone gaskets are being made in small and high volumes at various levels. There are two methods conventionally used. One is the cutting process, and the other one is the punching process.

Although both methods are used depending upon the characteristics of the product, they have their own significance.

- Punching method

This method involves a Rule Forme to punch into the sheets with the help of the hydraulic press. A Rule Forme is a bent steel strip with one sharp end.

This sharp end consists of a blade that helps in punching large and small gaskets. Some gaskets that require holes are also punched by small Hole punches.

- Cutting method

This method involves cutting gaskets through large sheets. The precise cuts can be made through a water jet or laser.

In Water-jet cutting method, a sheet of silicone is cut via a high pressure jet. Similarly, in laser cutting, a high beam of laser is used to make precise cuts. Hand cutting and strip cutting are some other methods that are done by knives.

The cutting method produces less waste as it does not cause any deformation. Hence, it is often preferred over the punching method. However, substances other than the silicone that can absorb water are not suitable for water jetting.

![]()

4. Does Silicone Make A Good Gasket?

Silicone has various properties that assure that silicone is the best material for gaskets. Well-known manufacturers like Baiwesilicone also use silicone for the manufacturing of their gaskets.

Below are a few properties of silicone, in rescue, to prove silicone as the best material for gaskets.

- Flexibility

Silicone is a highly flexible material. It can be molded into different shapes due to its flexibility. The secret service of its flexibility lies in its chemical bond.

Silicone is made by joining two oxygen atoms to a silicon atom. This bond can be easily made and broken, making the chain flexible.

So when making gaskets, this property is kept in mind because gaskets need to be flexible. And as we need gaskets in various forms and shapes, silicone is the best material to choose.

- High tensile strength

Silicone has high tensile strength. That means no matter how much force you apply to the material, it never breaks easily. This property urges us to make gaskets of silicone material. As we need gaskets to be durable and long running.

Moreover, its high tensile strength also ensures airtight pressure between the two surfaces. So silicone provides excellent sealing to prevent leakages.

- Temperature resistant

Another reason to use silicone material in the manufacturing of gaskets is that it is temperature resistant. It can withstand extreme temperatures.

Silicone is the material that can tolerate -55 degrees Celsius in the lowest temperatures. And +300 degrees Celsius in the highest temperatures. So it makes a good match for gaskets that need this property.

- Soundproof and waterproof

Silicone also has the ability to resist noise. And we need gaskets for doors and windows for the purpose of soundproofing. Hence, silicone serves best for door gaskets.

Silicone is also water repellent. It doesn’t absorb moisture nor does it deform when exposed to any liquid. And gaskets used for beverages require this property. So another reason, silicone is the best material for gaskets.

- FDA approved

Silicone is an FDA approved material for use in the medical and food industries. This is due to its chemical resistance property.

It serves as a barrier and makes sure that no chemical can pass through. Moreover, it also doesn’t react with food and drugs. So it is preferred to use in Food Grade Silicone Gaskets.

![]()

5. What Is The Difference Between Gasket Sealer And Gasket Maker?

Both are made of silicone material. They have just a minor difference in their grade.

Gasket sealers are typical gaskets that are used for sealing and shielding. However, Gasket Maker is a type of Gasket Sealer that is specifically used for metal flanges, oil pans, and on paper or cork.

Gasket makers are further classified into three types:

- Fast drying, fast hardening

- Slow drying, brushable

- Non hardening

- Do You Need Silicone For Oil Pan Gasket?

Yes, silicone gaskets are useful for oil pans. Silicone provides excellent sealing and prevents leakage. So it’s good to place silicone gaskets at sensitive areas where there is a risk of leakage.

A pressed steel pan can go well with rubber gaskets. But aluminum oil pans need silicone gaskets for proper sealing and prevention of leakage. Oil pan gaskets are positioned between the engine block and the oil pan.

Oil pan gaskets not only prevent leakage, but they serve as an anti-vibration. They control the unnecessary vibrations produced by the engine. And in this way, it saves the vehicle from any damage.

Moreover, it also resists heat and pressure. And here is where silicones serve the best.

![]()

- Why Is Silicon A Preferred Material For Gasket?

Silicone is a preferred material for gaskets due to its extraordinary properties that are suitable for gaskets. Some of the other reasons are:

- It is highly flexible and can be molded into any shape easily. And we need gaskets in various forms and shapes, silicone is the best material to choose.

- The temperature resistance of silicone ranges from -55 degrees Celsius to +300 degrees Celsius. And one purpose of gaskets is to save from extreme temperatures.

- A very particular reason that silicone is preferred especially in food grade and medical gaskets is that it is an FDA approved material.

- Silicone doesn’t absorb moisture. It is waterproof. That is why it is preferred for gaskets used in beverages.

- It is unbreakable due to its high tensile strength, which makes the gaskets highly durable.

- It ensures airtight pressure between the two surfaces. And this helps in preventing leakage and sound reduction.

- Silicone is also soundproof. That is why it is used in gaskets for doors and windows for the purpose of soundproofing.

- It is chemical resistant and so preferred in gaskets for food processing.

6. What Are Die Cut Silicone Gaskets?

Die cutting process is used to make Die cut silicone gaskets. This method involves a metal tool known as ‘Die’. It is used with a mechanical press to form various shapes of gaskets.

Die is basically a cutter that is placed on the material that needs to be cut. Above the die is the hydraulic press, which presses the die into the material and makes the desired shape cuts.

There are both manual and automated die cutters. Manual die cutters are used by trained experts only. So they produce low volume but accurate silicone gaskets.

However, automated die cutters work automatically. It produces a high volume of silicone gaskets. But the waste material produced by such die cutters is comparatively high. Moreover, CNC machine die cutting is also used.

Due to the cost effectiveness of this method, it is widely used to produce high volumes of silicone gaskets. These gaskets made with die cutting are used in LEDs, LCDs, and battery pads.

![]()

7. What Are Different Silicone Rubber Grades Available For Gasket Manufacturing?

Different silicone rubber grades available for gaskets manufacturing include:

- Die cut Gaskets

- Food Grade Gaskets

- Molded Silicone Gaskets

- Fluorosilicone Gaskets

- Conductive Silicone Gaskets

8. What Are Molded Silicone Gaskets?

Molded Silicone Gaskets are gaskets that are molded with various molding techniques. These techniques include LSR Injection molding, silicone compression molding, and silicone over molding.

Such types of gaskets are useful for products that do not have regular shapes and forms. So where there is a need for irregular shapes, molded silicone gaskets are used.

This is because regular shape gaskets do not completely fulfill the purpose for which they are used. Gaskets need to be airtight when placed on any surface. And irregular shaped gaskets can still leave a space behind. However, with molded gaskets, there is better tolerance.

Molded gaskets also produce high volume and less waste material. However, Molded Silicone Gaskets are more expensive than Die Cut Gaskets.

![]()

9. What Are Conductive Silicone Gaskets?

Conductive Silicone Gaskets are the ones used in electronic devices. They are also known as EMI Shielding Gaskets. Both names are placed on their meaning.

Conductive Silicone means that they are conductors and can conduct electricity. The other name is again on purpose. It is used for shielding in various electronic devices.

Such gaskets form a path for the flow of current in electronic devices. It works as a shield and protects the current. It prevents interference and ensures a smooth flow of current. It blocks the potential difference inside the gasket.

10. What Are Food Grade Silicone Gaskets?

The silicone gaskets that are specifically made for food processing industries. They are known as Food Grade Silicone Gaskets.

They are FDA approved and follow all the safety measures. Such types of silicone gaskets need additional care and safety.

A non toxic material is always chosen for Food Grade Silicone Gaskets. So that it never becomes contaminated when comes in contact with the gasket itself.

Also, it is made sure that the food gaskets must withstand extreme temperatures. And maintain the indoor temperature as the optimum required by the food inside.

For breweries, maintaining the taste is a challenge to industries. So they use such material that doesn’t affect the flavor of beverages. And here is where again, Food grade silicone gaskets are used.

![]()

11. Where Are Fluorosilicone Gaskets Used And How Are They Manufactured?

Fluorosilicone Gaskets come with additional resistance than silicone gaskets. This is due to the difference in the chemical structure of both.

Fluorosilicone Gaskets contain a trifluoropropyl group that gives them properties similar to fluorocarbons. So whenever there’s a need for high end gaskets, Fluorosilicone gaskets come in its defense.

They are used in oil pans, engine gaskets, O rings, exhaust gas, and electrical appliances. Moreover, they are manufactured from the Punching and Cutting process.

Punching is done by a Rule Forme that punches into the sheets with the help of the hydraulic press. And gaskets are made.

While cutting involves Die cutting, strip cutting, laser cutting, and water jetting.

12. Can I Get Customized Size Silicon Gaskets?

Yes, Baiwesilicone takes orders for customized silicone gaskets. Not only the size, but you can customize the material and quality of the gasket as well.

They have specialists who can make gaskets of any size and design. You can also choose the technique by which you want your gaskets to be made either punching or cutting.

They offer a variety of silicone gaskets including Food grade Gaskets, molded gaskets, EMI gaskets, Fluorosilicone gaskets, and die cut gaskets.

![]()

13. How To Choose The Best Silicone Gasket Manufacturer From China?

For finding the best one, you have to do some research.

Search:

Search on the Internet. When you track down some good manufacturers, shortlist two or three of them.

Contact them:

Contact them by sending an email. Discuss with them your requirements in detail. Ask them about their quotation.

Compare:

Once you get back a response from them, compare each manufacturer. Note the quotations and services of each.

Customer reviews help a lot. Go on the website and read customer reviews of each. And then compare them while keeping in mind the experience of previous buyers.

Choose the right one:

After comparison, choose the best one while keeping in mind the following:

- Experience

- Shipping

- Quotations

- Services and after sale services

Whoever offer’s suits you is the best one for you.

We recommend you Baiwesilicone. It is a Chinese manufacturer with fifteen years experience.

14. Do Chinese Manufacturers Produce Good Quality Silicone Gaskets?

Indeed, there are numerous productive makers of silicone gaskets in China.But if you want a reliable option. It is the best silicone rubber products company with excellent services at affordable prices.

They have had expertise in this field for over fifteen years. It guarantees to be a reliable accomplice with regards to satisfying the cravings of clients. They have specialists who work day and night in assembling precise and accurate products.

Baiwesilicone ensures you provide the same quality regardless of the size of the order. They can efficiently manage larger orders in less time as they have three plants. Moreover, they have a skilled team that is committed to their work and improving the production of the company.

![]()

15. How Much Time Is Needed To Deliver A Batch Of Silicon Gasket To My Country?

It depends on several factors but mostly the size of your order. High volume batch requires more time than a low volume. On an average, it takes 15 to 20 days to deliver a batch of silicone gaskets to Europe.