Plastic injection molding is one of the most versatile and cost-effective manufacturing processes in the modern world. From toys and appliances to automotive components and medical devices, injection molded parts are ubiquitous across industries.

But what exactly is plastic injection molding and how does the process work?

In this comprehensive guide, as a professional plastic injection molding manufacturer, I’m going to walk you through everything you need to know, including:

- What is Plastic Injection Molding

- How injection molding works, step-by-step

- The components of an injection molding machine

- The basics of injection mold tool design

- A comparison to other plastic molding processes

- And more…

Let’s dive in!

What is Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process for producing parts by injecting molten material into a mold. It combines efficiency, versatility, and precision. This technique is particularly effective for creating complex shapes and high volumes of identical items, making it a cornerstone of modern manufacturing, especially for plastic products.

How Plastic Injection Molding Works

Plastic injection molding is the manufacturing process used to create plastic parts by injecting molten plastic material at high pressure into a mold.

The basic process has four main steps:

1. Plastic is Fed into the Injection Molding Machine

The raw plastic material, usually in small pellet form, is fed into a hopper on top of the injection molding machine. Common injection molding plastics include polyethylene (PE), polypropylene (PP), polystyrene (PS) and polyvinyl chloride (PVC).

2. The Plastic Pellets are Melted

The plastic pellets are fed into the machine’s heated barrel. A rotating screw helps push the plastic through the barrel, where heat and pressure melt the plastic into a liquid state.

3. The Liquid Plastic is Injected Into The Mold

When the molten plastic reaches the mold, it gets injected through a gate into the tool’s cavity. The buildup of pressure packs the cavity, allowing the liquid plastic to take its shape.

4. The Plastic Part is Ejected

Once the predetermined cooling time has passed, the mold opens and the solidified part gets ejected. The mold then closes and the cycle repeats.

And just like that, you have an injection molded plastic part! The entire process usually takes anywhere from 25 seconds to 2 minutes for each part.

Now let’s take a closer look at some of the key components and tooling involved.

Key Components of An Injection Molding Machine

There are three main components that make up a basic injection molding machine:

The Injection Unit

The injection unit, sometimes called a plasticator or plasticising unit, handles the melting, mixing and injection of the plastic.

Key parts of the injection unit include:

- Hopper: Stores the plastic pellets before they enter the heating barrel.

- Barrel: Houses the reciprocating screw. Heaters surround the barrel to melt the plastic as it gets pushed through.

- Reciprocating screw: Feeds plastic through the barrel and builds up injection pressure.

- Nozzle: Connects the barrel to the mold and conveys the molten plastic into the tooling.

The Clamping Unit

The clamping unit opens and closes the mold halves and provides enough force (clamp force) to keep the tool securely closed during injection. This prevents any leaks while the mold fills.

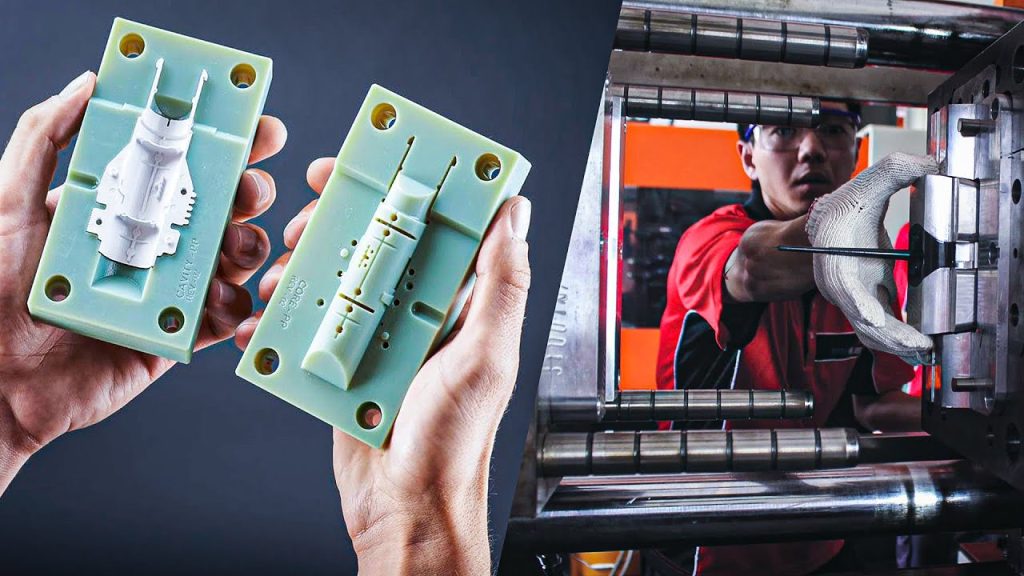

The Mold

The mold, made up of the cavity and core halves, gives plastic parts their shape. The cavity is the fixed half that forms the exterior of the part while the core forms interior details.

Advanced injection mold designs may include additional components like ejector pins, cooling channels and slides. We’ll dive deeper into injection molds next.

The Basics of Injection Mold Design

Because injection molds can cost upwards of $100,000 to fabricate, putting extra thought into the tool design is crucial.

Here are some important design considerations and common features found in many injection molds:

Draft Angles

Applying draft angles (>1°) to vertical surfaces allows parts to release cleanly from the mold. Without draft angles, parts could get stuck inside the tool.

Ejector Pins

Ejector pins push finished parts out of the mold cavity once the mold opens. Their numbers and placement depend on part geometry.

Cooling Channels

Running water or oil cooling channels close to the mold cavity regulates tool temperature more efficiently, shortening cycle times.

Slides

Slides allow for the fabrication of parts with undercuts and complex geometries by providing additional space inside the mold to form challenging areas.

Proper injection mold design is critical for manufacturable, functional plastic parts. An experience mold maker can assess your design and provide feedback to avoid issues.

How Injection Molding Compares to Other Plastic Molding Processes

While injection molding excels at producing large volumes of plastic parts quickly and efficiently, other molding processes offer their own advantages.

Here’s a brief overview of popular alternatives and how they compare:

Blow molding uses compressed air to inflate softened plastic inside a mold cavity to make hollow parts like bottles and containers. The process wastes very little material but has longer cycles.

Compression molding uses external pressure and heat to mold parts in an open mold cavity. It works well with glass- and mineral-filled plastics but has low automation potential.

Thermoforming heats a plastic sheet before pulling it into shape inside a mold cavity using vacuum suction or mechanical force. Simple parts like food trays can be made rapidly and cheaply but with less consistent wall thicknesses.

Rotational molding continually rotates biaxially while coating the inside surfaces of a mold to make large hollow parts like tanks and kayaks. It produces seamless, one-piece parts but with extended cycle times.

3D printing uses an additive layer-by-layer approach to fabricate complex geometries without dedicated tooling. But parts have inferior mechanical properties and surface finishes compared to injection molding.

Each process comes with tradeoffs around factors like automation, tooling costs, part properties, maximum part sizes and production volumes. With an eye toward these constraints, manufacturers can select the optimal molding technology for an application.

The Bottom Line

As you can see, plastic injection molding is an extremely versatile production process capable of fabricating precision plastic components at scale across industries. While other molding processes have their place, injection molding offers perhaps the best balance of efficiency, consistency and part performance.

The basics of injection molding boil down to heating plastic resin until it liquefies, injecting it into a mold, letting it cool and solidify, then ejecting the finished part. But mastering the nuances around machine components, injection mold design and comparing the process to alternatives enables smart manufacturing decisions.

I hope this comprehensive overview gave you a helpful understanding of what plastic injection molding entails. If you have any other questions, feel free to drop them in the comments below!