Rubber Moulded Components Factory

We’re operating in China, Baiwe is well-known to offer satisfying services and quality rubber moulded components. Our wide experiences enable us to create high-precision rubber moulded components for many companies around the world. During the past 15 years, Baiwe manufactures custom rubber moulded components that meet every industries and technologies standard. If you want to learn more about Baiwe rubber moulded components, contact us!

Due to our rich experience, we can customize automotive rubber moulded parts to your accurate specifications. It features long-lasting, flexible, and premium quality.

We manufacture custom rubber moulded components available in 10mm, 16mm, 22mm, 25mm, and more diameter measurements. Most usable in the automotive industry.

We process our high-quality rubber moulded components through cutting, molding, and injection, It is accessible in various colors and sizes.

Baiwe processes high standard rubber moulded components with standard and custom sizes. Ideal to electronics, automotive, and more industries.

You can avail our industrial rubber moulded components with different colors like red, black, and more. We process this product through compression molding and die-cutting tools.

ISO-certified rubber moulded components are suitable for automotive, heavy industries, mining, retail industries, and more. We are using raw materials such as silicone and EPDM in production.

We offer nonstandard rubber moulded components with various thicknesses and sizes. Standard sizes available are 10mm, 16mm, up to 25mm.

All our precision rubber moulded components are high-temperature resistance, oil-proof, waterproof, etc. We process the product through cutting, molding, and injection.

We can be your perfect rubber-metal moulded parts manufacturer and other rubber silicone products. These feature excellent performance and superior durability.

Our silicone rubber products come in different thicknesses and sizes to fit your accurate applications. It has different surface treatments to improve functionality.

We offers broad selection of universal rubber moulded components for you to choose from. These are ideal for automotive, plumbing, and other applications.

Our versatile rubber moulded components are highly customizable to your exact specifications. It has dust-proof, good performance, and waterproof characteristics.

Baiwe: One-Stop Solution Provider For Your Rubber Moulded Components Project

Baiwe, with over 15 years of experience, can be your relevant rubber moulded components manufacturer and custom-maker in China. Since then, we commit ourselves to serve customers with fast and cost-effective services. We can guarantee reliable, long-lasting solutions for your business.

No doubt, you can find the best solution for your rubber moulded components in Baiwe. We can’t wait to work with you and build strong partnership. Contact us now immediately!

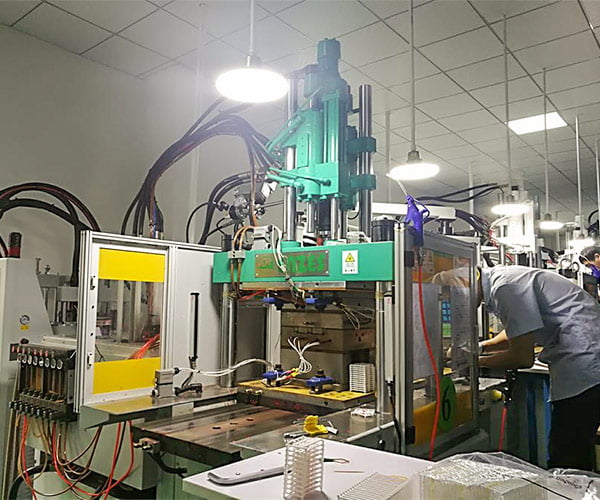

- Manufacturing

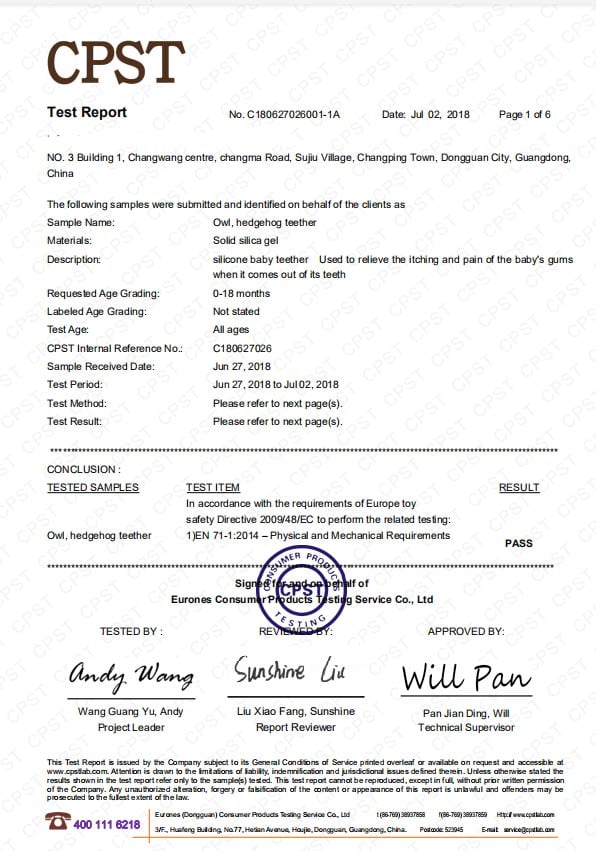

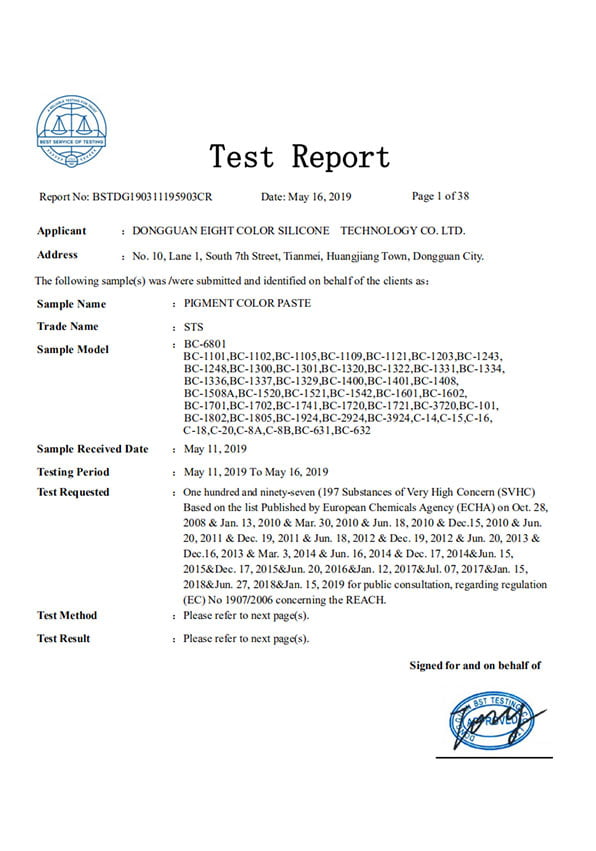

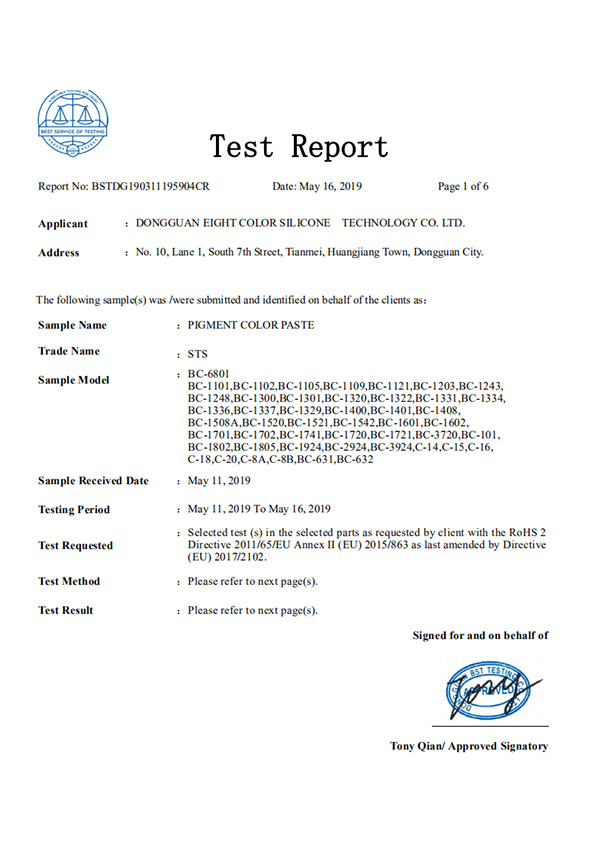

- Certifications

- Top Quality Control

Baiwe- Your Professional Rubber Moulded Components Manufacturer

Baiwe has full capabilities to manufacture custom rubber moulded components. We can handle the entire production to create the most efficient solutions. We’re operating in China, offer satisfying services for custom rubber molding. Enabling us to produce highly-precision rubber moulded components to your exact specifications.

As your leading rubber moulded components manufacturer in China, we can accommodate you in the design and material selections. Baiwe has 15+ years of experience with the also skillful design team that makes your ideal rubber moulded components a reality.

Besides, our rubber moulded components are highly customizable to your accurate specifications. These can fit your applications and working environment as well. Assuring that we can custom-make your rubber moulded components will give a stress-free experience.

Since rubber moulded components are one of the industry`s top-selling rubber products, we can manufacture them for you. And if you’re seeking the best rubber moulded components manufacturer, Baiwe is your ideal go-to source. Baiwe has more than 15 years in manufacturing rubber moulded components for different companies in the world.

Due to its versatility, affordability, and flexibility, Baiwe rubber moulded components are the most preferred for any application. All are 100% durable and reliable products that will withstand many elements like heat and cold. Other advantages include low cost, high strength, fast production time, availability in many shapes, and chemical resistance.

Baiwe rubber moulded components are applicable in numerous industries. Ideal to the military industry, semiconductor, industrial, electronic, medical, automotive, solar, biotechnology, solar, etc.

The continuous process and upgrade tooling improvements enable us to maintain our leadership in the custom rubber molding field. Our company, Baiwe, can work with customers, from the design process to the production stage. Whether your choice is high-volume production or prototype run, we offer multi-cavity and single tooling with reasonable tooling costs.

You can always count on us for your custom rubber moulded components. Contact Baiwe to learn more about our capabilities or request technical help.

Rubber Moulded Components- Ultimate FAQ Guide

Are you looking for high-quality rubber moulded components? Not sure which one is the most reliable manufacturer?

We are got the solution for you,

Presenting you all the essential information about rubber moulding. By the end of this guide, you’ll be able to choose the authentic and genuine rubber moulded component supplier.

Let’s get started.

1. What’s Are Rubber Moulded Components?

2. What Are The Benefits Of Rubber Moulded Components?

3. How Long Rubber Moulded Components Last?

4. What Are The Types Of Rubber Molding Methods Use For The Manufacturing Of Rubber Molded Components?

5. What Are The Different Material Options Available For Rubber Moulded Components?

6. Can You Order Colored Rubber Molded Components From China?

7. What Is General Process Used For Rubber Moulded Components Manufacturing?

8. What Are The Uses Of Rubber Moulded Components In Different Industries?

9. What Are Different Rubber Moulded Components That Can Be Manufactured From Rubber?

10. What Are The Factors To Consider Ordering Rubber Moulded Components From China?

11. How Much Does It Cost To Manufacture Rubber Moulded Components?

12. Who Manufactures Rubber Moulded Components?

13. What Are The Quality Standards Of Rubber Moulded Components From China?

14. What Is The Difference Between Custom Molded Rubber Components Vs. Standard Rubber Components?

15. Should You Use Natural Rubber Or Synthetic Rubber For Rubber Moulded Components?

16. How To Choose The Right Rubber Moulded Components Manufacturer From China?

17. Does Chinese Manufacturers Provide OEM/ODM Service For Rubber Molded Components?

What are Rubber Moulded Components?

Rubber moulded components are those parts that are manufactured with uncured elastomers or rubber.

The process produces reusable rubber components with sufficient memory for reverting to their original position each time after pressure is applied.

Moreover, these rubber components are derived from natural sources, though the majority of them are manufactured with synthetic materials.

Consequently, the rubber moulded components are created by exerting pressure on a rubber block in the metal cavity.

Furthermore, the unit is exposed to heat and adopts the desired shape, such as hoses, harness grommets, dust covers, gaskets, etc.

Most industries and manufacturers are using heat and pressure techniques to produce high-quality and efficient rubber moulded components.

![]()

What are the Benefits of Rubber Moulded Components?

The benefits of rubber moulded components are many due to their versatility, flexibility, and affordability.

Moreover, many brands prefer rubber-made materials for their heat resistance, durability, reliability, and ability to withstand variable temperatures.

Various benefits of rubber moulded components include:

- The production of rubber components is cost-effective and requires less time in manufacturing.

- All the rubber components possess high strength and are durable to last for years.

- Generally, these rubber components can be molded into any shape that didn’t even exist before.

- Due to their non-reactive nature, rubber components are beneficial in many industries as they are resistant to chemicals.

Moreover, companies like Baiwesilicone offers the manufacturing of many customized rubber molded components for many applications.

Subsequently, the company provides highly efficient seals for various machines and applications at wallet-friendly rates.

![]()

How Long Rubber Moulded Components Last?

Rubber moulded components can last for 3 to 5 years, depending on their usage and the amount of care provided.

Moreover, several analyses have indicated that rubber components can retain their shape and sizes for longer periods if used within the moulds for which they are designed.

Furthermore, the proper storage and suitable temperature conditions also help prevent the deterioration of rubber moulded components.

Typically, the rubber components should be stored in a dark, cold, dry, and oxygen-free environment to slow the process of rubber degradation.

However, if the rubber part starts damaging, replacing or repairing the part is not costly. With suitable restoring techniques and care, rubber components can be restored to their original state.

What are the Types of Rubber Moulding Methods Used for the Manufacturing of Rubber Moulded Components?

The types of rubber moulding methods used for the manufacturing of rubber moulded components are briefly discussed as follows:

1. Injection Moulding

Like compression moulding, injection moulding also implies using heat and pressure to force the rubber to adopt the new shape.

During this method, however, the material is heated until it reaches the plastic state and then introduced into the cavity under high pressure through the vulcanization process.

Moreover, this moulding method holds the advantage of providing high precision, meeting complex geometries, and consistent productivity.

2. Liquid Silicone Rubber (LSR) Moulding

This technique is considered a subset of injection moulding but specifically works with liquid silicone to manufacture products.

Furthermore, two materials are used in the process, mainly a base and a catalyst combined during the process.

Additionally, the technique provides suitable prototyping for full-scale productions and is suitable for various industrial applications.

3. Compression Moulding

This method applies comprehensive pressure and heat to uncured rubber to convert it into the desired size and shape.

Additionally, the process involves the closure of rubber into a moulded cavity which is then heated up and cooled down once it forms the shape.

As compared to other moulding procedures, compression moulding offers the least tool costs, quickest lead times, and easy prototyping.

![]()

What are the Different Material Options Available for Rubber Moulded Components?

The different material options available for rubber moulded components are listed below:

1. EPDM

The reason behind EPDM’s popularity is resistance against UV and ozone at temperatures ranging from -60 to 250 degrees F.

Due to this property, it is a prime choice by manufacturers for outdoor equipment; however, it is vulnerable to petroleum and oil products.

![]()

2. Neoprene

Neoprene is an excellent elastomer but has less resistance against strong acids and bases that limit its usage.

3. Viton

Under elevated temperatures and high exposure to chemical environments, Viton is the ideal material to go with.

Unfortunately, the use is limited due to the narrow hardness range and less potential against harsh chemicals like ketones, hydrocarbons, etc.

4. Silicone

Silicone offers high purity levels when processed, enabling its use in sensitive applications, including food processing and medical operations.

Furthermore, it exhibits high durability, resistance against UV and ozone but possesses less potential under the action of fuel and other solvents.

5. Nitrile

Nitrile is known for providing high resistance against oil, grease, solvents, and fuels. However, it shows poor resistance against hydrocarbons and ketones.

![]()

Can You Order Colored Rubber Moulded Components From China?

To order colored rubber moulded components from China, it is necessary to choose a reliable and trustworthy supplier like Baiwesilicone to avail best services.

In the past 15 years of service, the company has adopted all kinds of latest techniques and methods to fulfill consumers’ demands.

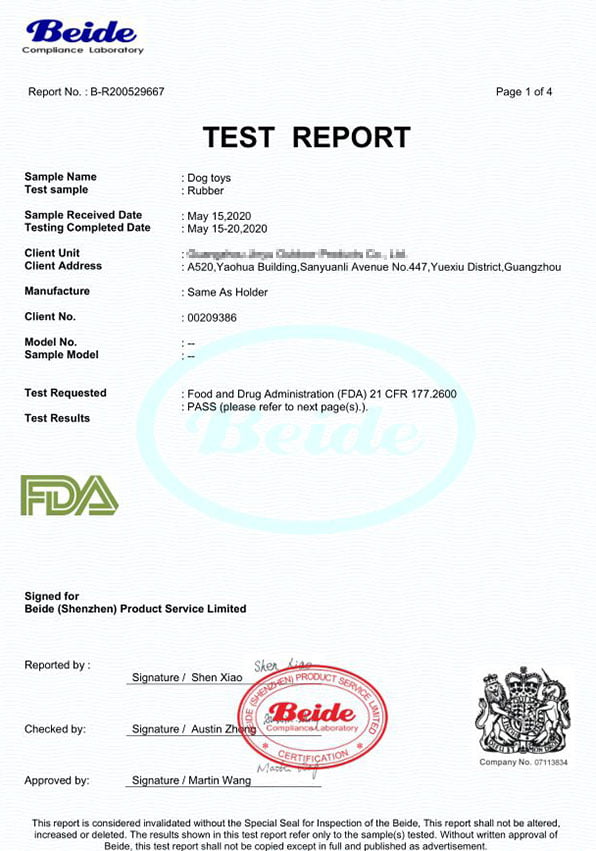

Moreover, the company has successfully passed all the audits and is certified to produce genuine and authentic rubber moulded components.

Not only is the factory capable of producing small orders, but they can also manufacture large orders with equal maintenance of high quality and precision.

What is the General Process Used for Rubber Moulded Components Manufacturing?

The general process used for rubber moulded components manufacturing is by converting the uncured rubber into usable rubber products via vulcanization reaction.

Typically, the process involves placing, forcing, and injecting the component into a moulding cavity, and heat and pressure are applied unless it adopts a new shape and texture.

Furthermore, this process is suitable for rubber moulding because it induces long polymer chains and prevents them from moving independently.

Generally, this process effectively manufactures a wide range of rubber parts with high efficiency and strength for both customized and standard products.

What are the Uses of Rubber Moulded Components in Different Industries?

The uses of rubber moulded components in different industries have created new dimensions to explore the limitations.

Whether the components have to be customized or standard sized, they are effective for many industrial sectors, including:

- Medical Industry

- As a Semiconductor

- Military and Defense Industry

- Food Processing Industry

- Automotive Industry

- Water Filtration Processes

- Solar Sector

- Gas and Oil Industry

- Biotechnological Sector

- Electronics Industry

- Agricultural Sector

- Municipalities

- Aerospace Industry

What are the Different Rubber Moulded Components that Can be Manufactured from Rubber?

The different rubber moulded components can be manufactured from rubber as they are beneficial for almost every industrial sector. Some are mentioned below:

- Rubber seals and gaskets are manufactured from the rubber to resolve the sealing issue in many applications. It keeps the unit isolated even at elevated temperatures.

- The colored rubber moulded parts are manufactured to distinguish similar parts, enhance safety, reinforce brand identity, and ease assembling any product.

- The industrial electronic sector uses rubber to make protective boots, sleeves, and covers to create resistance to environmental conditions.

- Moreover, the various rubber grommets produced in the industry develop all types of grommets like split grommets, compression grommets, and panel grommets.

![]()

What are the Factors to Consider Ordering Rubber Moulded Components from China?

Various factors to consider when ordering rubber moulded components from China are essential to choosing a supplier with professional behavior and durable services.

For long-lasting services, you can always rely on Baiwesilicone for high-performance products.

With constant improvements and process upgrades, they ensure to deliver the premium services which have made them leading rubber moulded parts suppliers.

Moreover, they work with the clients to know their design requirements and produce the best-customized products.

Whether a consumer needs customized rubber seals, grommets, or covers, they proudly supply every part in every industrial sector.

What is the Cost of Manufacturing Rubber Moulded Components?

Analyzing the cost of manufacturing rubber moulded components is essential to make sure you stay within the budget.

Mainly, many companies are offering these services at reasonable rates and have structured their catalog online to serve more consumers.

Usually, the average price range of customized rubber tooling costs somewhere between $500 to $3,500, depending on the complexity and type of the part.

Moreover, the rubber moulded parts are considered the most cost-effective portion of any design, and they possess high resistance qualities that make them superior to other components.

Who Manufactures Rubber Moulded Components?

Baiwesilicone has manufactured rubber moulded components in China for 15 years with high efficiency and cost-effective rates.

As the leading supplier, the company’s main focus is to generate the best rubber moulded parts by implementing the latest technology and modern techniques.

Furthermore, the company has invested in 3 plants for mould making, silicone rubber compression technique, and injection moulding processes.

They can effectively meet the ordinary order requirements, but they can also fulfill the large order demands by consumers with a high standard of products.

What are the Quality Standards of Rubber Moulded Components from China?

The quality standards of rubber moulded components from China are developed by Rubber Manufacturers Association (RMA).

For the maintenance of quality, the association has introduced tolerance tables to define the ranges of products.

Moreover, it has provided a way of communication between a user and a wide range of industries and discusses the designs and production of new parts.

All the rubber moulded components industries must obey this table and produce the parts accordingly, whether customized or standard.

What is the Difference Between Custom Moulded Rubber Components vs. Standard Rubber Components?

The major difference between custom moulded and standard rubber components is that standard sizes might not always be the right fit for your application.

While customized rubber moulded components can always be a perfect match for your application in terms of fitting and efficiency as well.

Moreover, the standard rubber components have a template design and drafted products that are ready to go.

However, it is not always possible to fit standard rubber parts due to their complex geometries. To that end, customized rubber components are always the right choice.

![]()

Synthetic Rubber or Natural Rubber? Which is Better for Rubber Moulded Components?

Synthetic rubber or natural rubber both are better for rubber moulded components according to their respective properties and characteristics.

For instance, natural rubber components have a better resilience rate,i.e., they can return to their original state quickly.

Plus, it can withstand tearing, cutting, and chipping better than synthetic rubber.

On the other hand, synthetic rubber parts are malleable, shapeable, and more economical and can be used conveniently in many applications.

How to Choose the Right Rubber Moulded Components Manufacturer from China?

To choose the right rubber moulded components manufacturer from China, the better and clever option is to select experienced and professional suppliers.

To that end, you must select a leading rubber moulding industry in China like Baiwesilicone. They are known for their high-quality and highly efficient products.

Within the past years, the company has proven to be the best supplier of rubber moulded components through various effective methods.

![]()

Does Chinese Manufacturers Provide OEM/ODM Service for Rubber Moulded Components?

Yes, Chinese manufacturers provide OEM/ODM service for rubber moulded components.

Over the past few years, the Chinese suppliers have evolved their business models to focus on providing the solutions to meet the consumer’s requirements.

Moreover, it has enhanced the value of brands and enabled them to produce more and boost their production capacities.

Furthermore, the quality and effectiveness of rubber moulded products are passed through a series of tests to ensure their efficiency.