We Have Advanced Equipment For Your Silicone Hose Business

Baiwe was established 15 years ago. After years of development in the silicone hose industry, we have become one of the best silicone hose manufacturers and suppliers in China.

We have enough ability to customize industrial silicone hose, food-grade silicone hose, medical silicone hose, and we can provide you with different sizes, different thicknesses, and different colors of silicone hose.

If you are looking for a silicone hose manufacturer and supplier in China, we can be your best choice. Pls send us your specific demand, we will offer you our best quote immediately.

Food grade liquid silicone gel for silicone hose

Custom made silicone hose with BPA free

Custom made silicone hose in different sizes

Custom made food-grade liquid silicone hose

Silicone hose made by liquid silicone molding with medical-grade silicone gel

High quality all types of silicone hose for your business

Baiwe:We Can be Your Best Silicone Hose Manufacturer and Supplier for Next Order

As a professional silicone hose manufacturer and supplier in China. You can get the following services if you cooperate with us

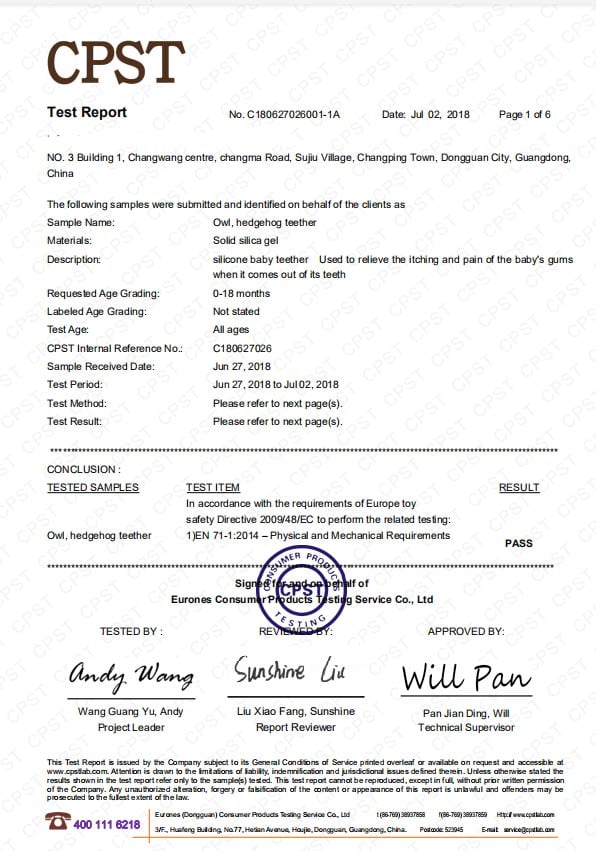

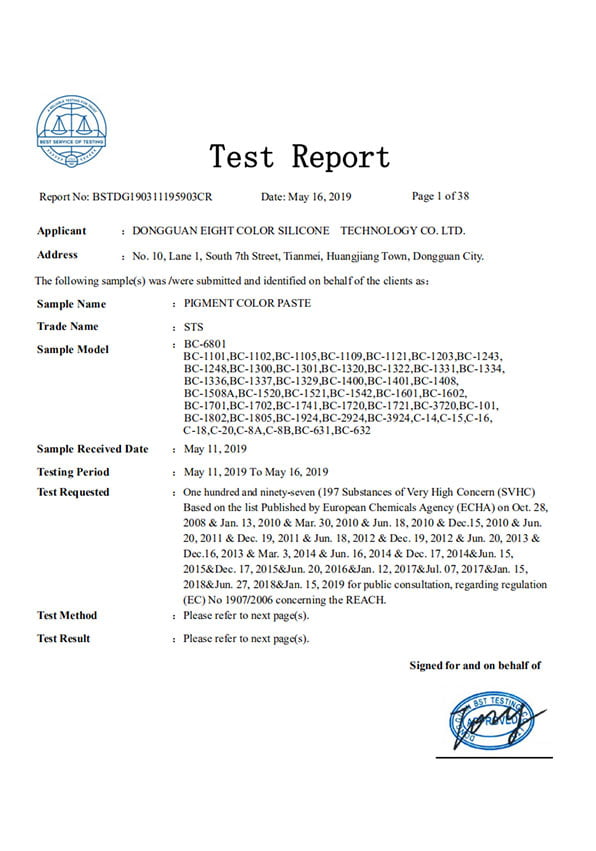

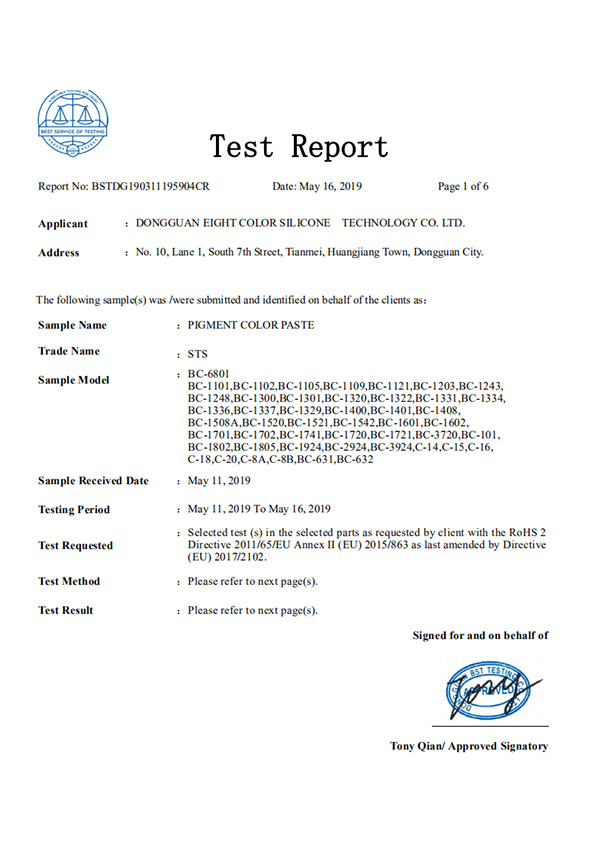

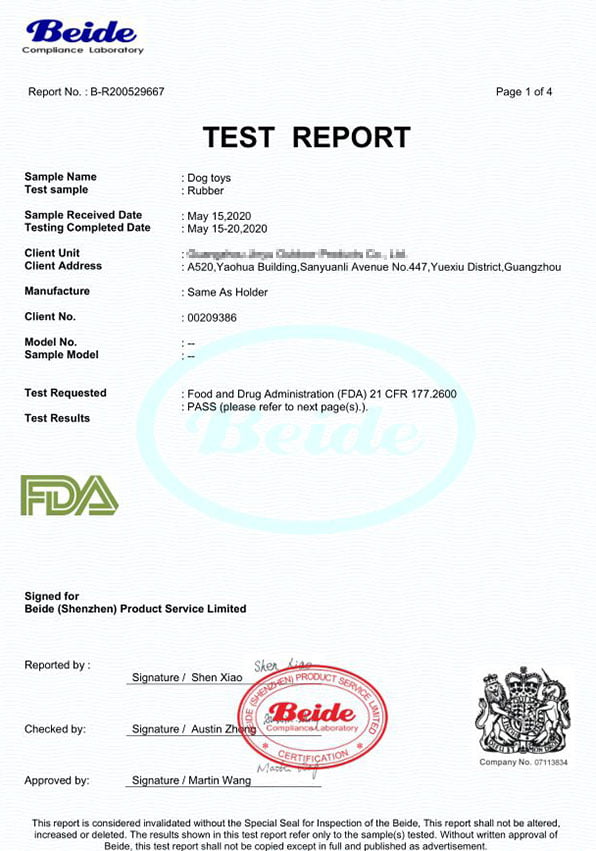

High-quality material selection: Our silicone has different levels of quality for you to choose, food-grade, medical-grade liquid silicone. Silicone hose has excellent heat resistance, platinum vulcanization, high transparency, and has passed relevant certifications, such as SGS, FDA, etc.

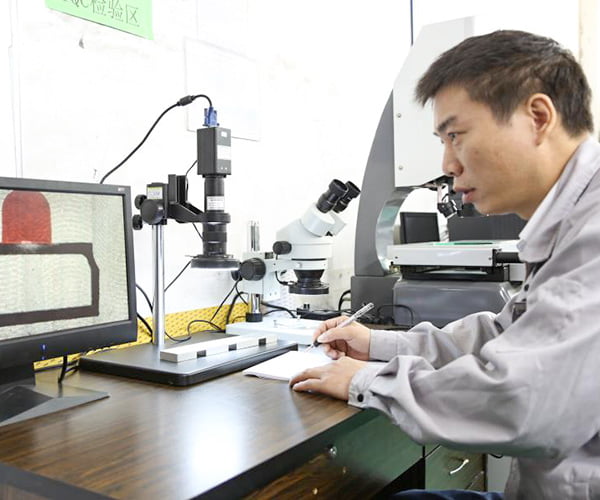

Excellent quality management system: As one of the leading silicone hose manufacturers and suppliers in China, we have been committed to optimizing our quality management system, to ensure that your silicone hose order gets consistent and high-quality services.

7/24 Professional service support: We have a team with an average working experience of more than 7 years to serve you. Now send us your requirements, and we will become your trustworthy silicone hose manufacturer and supplier for your next project.

- Manufacturing

- Certifications

- Top Quality Control

![]()

We Also Can Custom Made All Kinds of Silicone Parts For You.

Baiwe is a professional silicone parts manufacturer in China, we have our own high-precision CNC tooling-making technology, such as silicone compression molding, liquid silicone rubber injection molding, silicone overmolding, silicone transfer molding.

Are you in need of a silicone products project? Call us the support team right now, we will get back to you soonest.

Silicone Hose Ultimate FAQ – Ultimate FAQs Guide

You must be a business owner, and looking for silicone hoses of all types that can fit well according to your needs. Here in this Ultimate Hose FAQ guide, we will guide you through the basic to advance level questions regarding silicone Hose buying and manufacturing. SO Let’s get started!

- What’s A Silicone Hose?

- What Is Silicone Hose Used For?

- What Are The Different Types Of Silicone Hoses?

- Is Silicone Good For Vacuum Hose?

- Do Silicone Hoses Collapse?

- Can You Bend Silicone Hose?

- Is Silicone Hose Better Than Rubber?

- Is Silicone Hose Suitable For Oil?

- How Long Does Silicone Radiator Hoses Last?

- Can You Use Silicone Hose For Petrol?

- How Is Silicone Hose Made?

- How Do You Cut Silicone Intake Hose?

- Can You Paint Silicone Hoses?

- What Is A Silicone Hose Clamp?

- Is Silicone Hose UV Resistant?

- What Are The Quality Standards Followed By Chinese Silicone Hose Manufacturers?

- What Are The Steps Taken To Ensure The Quality Control For Silicone Hose Manufacturing?

What’s A Silicone Hose?

A silicone hose is a rubber pipe made of silicone material that has versatile uses.

These hoses are mostly found in machinery where a lot of heat and water has to move from one point to another.

![]()

These hoses help to move the coolant under high-pressure situations from one part of any engine of a vehicle to another point.

They are mostly used in diesel and gas engines, whereas in extreme engineering, they also found their use in charge air coolers and turbo.

A good quality silicone case has the capability to resist a temperature as high as 350°F.

It has great resistance to chemicals and good insulating properties for electrical currents.

With good flexibility in any kind of hostile engine situation, this material has a longer life than any black rubber material.

You can get the best silicone molding services for the hoses from the top manufacturer in China at baiwesilicone.

What Is Silicone Hose Used For?

A silicone hose is mostly used in vehicle engines where there is a lot of heat, and it makes the water move through radiator pipes easily.

It is also mostly used in vacuum pipes along with air ducting hoses and turbo boost hoses to resist high temperatures.

When a specialized type of silicone hose is used, it can easily carry any fuel and oil because of its excellent ozone and UV resistant properties.

These hoses are best suitable for extreme temperatures depending on the specific formulation that can make them usable in high or even low temperatures.

They are appropriate and best for automotive industries and food processing industries where they are used for cooling, process tubing, and even as turbocharger hoses.

The usage of these hoses makes them appropriate in outdoor applications because they don’t degrade even when they are exposed to environmental conditions.

These silicone hoses are also used in medical applications extensively.

What Are The Different Types Of Silicone Hoses?

Basically, there are three different types of silicone hoses.

General Purpose

General-purpose silicone tubes or hoses are of the first type that is suitable for a situation where no high pressure or compound purity is required.

They have great flexibility and thermal resistant properties due to silicone rubber products are suitable to fit any domestic appliance.

They are mostly used in automobile engineering, food processing, and even in the medical fields for carrying out tests and results.

Medical Grade

The other type of silicone hoses is the medical grade tubing, which is used for compound composition that helps to reduce the toxic properties of rubber.

Such type of tubes doesn’t react with any food ingredients or drugs, and they don’t even affect the body fluids or tissues.

These grades of silicone hoses can be used with pressurized gases or suction.

Heat Resistant

The heat-resistant silicone hoses are good-quality hoses or tubes that can resist high temperatures as they are raw materials that are used in specific environments.

Such types of hoses have good use in industrial use with high pressure and high-temperature environments.

They are thick, and they are mostly used for heater matric, water connecting, making them the ideal choice for intercoolers, intakes, and coolants.

Is Silicone Good For Vacuum Hose?

Silicone can be used for Vacuum hoses as it has the property to resist high-temperature conditions, which makes it ideal to be used.

![]()

It has benefits over a rubber vacuum hose because it has more flexibility, and it can withstand higher temperatures even more than a rubber vacuum hose.

Any vacuum application or a situation where temperatures may be elevated should be dealt with silicone hoses as they have a maximum support for high temp working conditions.

A standard silicone hose won’t is recommended for such a purpose, and you will need to use a specialized silicone hose from the best manufacturer in China.

Bauwesilicone industry is the best manufacturer of silicone hoses in entire China.

Do Silicone Hoses Collapse?

Silicone hoses can collapse if you use them in a vacuum, and it could lead to a lot of problems.

This can cause problems like incorrect gauge readings, high emissions, and even poor mileage for a vehicle, and sometimes engine stalling too.

![]()

The aftermarket silicone vacuum hoses are very thin that is not suitable to carry vacuum, which causes them to collapse.

Getting a specialized silicone hose can fix the problem as they do not crack and become hard over time.

They have a better life than rubber hoses which means a rubber hose will collapse before a silicone hose.

If kept with care, it is possible that silicone hoses last for life without getting ruined or needed to be replaced under any condition.

Can You Bend Silicone Hose?

It is a yes, and it is a no.

In case if it’s an old silicone hose, then it is not possible to bend it or mold it into any direction or shape.

It is dangerous to do so even if you use a heat gun as it would ruin the pipe and disturb its shape, and you won’t be able to bend it back again.

If you are using a new silicone hose with good flexibility properties, then it is possible to bend the silicone hose but only to some extent.

You should realize that bending too much with a heat gun can end up ruining your silicone hose, and it won’t be useful for anything at all.

Is Silicone Hose Better Than Rubber?

As compared to rubber, a silicone hose is always a better choice.

There are five reasons to explain it better.

Flexibility

This is because the silicone hose has higher temperature-resistant properties, and It can maintain its flexibility for a long time where rubber hoses cant.

This is why when silicone hoses are used in automobiles; they are always the same even after years with stretchable properties without becoming hardened and dry rotted.

Lifespan

Silicone hoses have a good and last-lasting capacity, which makes them an ideal choice over rubber hoses.

They can even last longer than the life of your car as most of them are offered for lifetime warranty due to their such great properties.

Operating Temperature Range

In thermodynamics, the silicone hoses perform better as they have good resistance to the temperatures and they operate pretty well.

A standard hose may expand under a lot of heat, whereas the silicone hose doesn’t get affected and stays the same by sticking to its properties.

They allow fluids to run through them even at high temperatures without even getting affected, unlike rubber that can get affected due to high temperature.

In extreme engineering, like building a racecar, it is always preferred to use a silicone hose instead of a rubber hose because of its versatile properties.

Noise and Vibration Control

Silicone hoses have good dampness properties, which can damp sound and vibrations easily.

This allows reducing noise or sounds for keeping a quiet and low profile.

Rubber can produce noise with the mating surface due to friction which is why silicone hose gets the point above it for better use.

Aesthetics

Silicone hoses can be made into different colors that are mostly preferred by car enthusiasts to show off their engine bays with more attractive pipes and hosing.

For the most part, the blue and red ones are the most used silicone hoses in cars that provide an attractive look on the inside under the bonnet.

Is Silicone Hose Suitable For Oil?

A standard silicone hose is not suitable to be used with oil.

This is because the property of such silicone hose is porous, and the grade is specifically formulated so that the oil cannot penetrate through the wall.

For use with oil, a fuel-grade rubber hose is needed to work properly, along with an oil-air separator that can trap the oil to the other side instead of going to the intake.

How Long Does Silicone Radiator Hoses Last?

On average, a silicone radiator hose will last more than 10 years.

This is because silicone hoses have high resistance and good properties to suit any environmental conditions, which makes them last a longer lifetime.

You can get the best silicone radiator hoses from Baiwesilicone, which is the best silicone hoses manufacturing industry in China.

Can You Use Silicone Hose For Petrol?

Silicone hoses are not meant to be used with oils and fuels like petrol.

They are specifically formulated in order to prevent oil and such fluids as they are fluoro silicone liners.

They are not recommended to be used for any Fuel lines or heavy use of Fuel Filling.

It’s better that these materials should not be exposed to solvents or fuels.

How Is Silicone Hose Made?

A silicone hose undergoes a lot of extrusion processes from which the silicone tubing is produced.

Following is the procedure for how silicone hoses are made.

- The first stage is milling for materials.

- Then scheduling and calendaring is the next step.

- Then cutting and tube rolling.

- After that, the company starts to build it with taping.

- Then curing, demoulding, and trimming takes place.

This process allows the silicone rubber to improve some of its attributes and other properties to maintain to make it acceptable worldwide.

A food-grade silicone hose is produced with a technical process by using either a platinum cure system or the hydrogen peroxide cure system.

This involves textile reinforcement and steel wire helix as well.

Baiwesilicone makes the best silicone hoses in entire China from where you can get the best ones for your business.

How Do You Cut Silicone Intake Hose?

A silicone hose cannot be cut by any ordinary instrument, which is why there are few ways through which you can cut a silicone intake hose.

Laser slicing is the best and effective method to cut silicone intake hose because the deeper the cuts formed by the laser, the easier it gets to remove the silicone intake hose.

This process helps to avoid any frictional deformation for the material, and sometimes another method of using cold cuts by freezing the silicone is helpful to cut the intake hose.

If a silicone hose is small in diameter and thin in material, then it can be cut by using a sharp knife or a blade.

In case you are interested in cutting large diameter silicone intake hoses, then here are the instructions.

- You will need to get a T bolt hose clamp that should match the size of your hose.

- Then you need a spanner for the clamp with a sharp blade or a knife for cutting.

- Mark the area with a pen or market where you want to cut.

- Then align the clamp, and make it tight on the silicone hose.

- Now start to cut by using the edge of the clamp as your guide to reach the bridge of the clamp.

- Then reach the point and rotate the clamp once again to cut the other half in the straight line.

- In this way, you can cut the silicone intake hose by using a blade and remove the clamp afterward.

Can You Paint Silicone Hoses?

Silicone hoses cannot be applied with ordinary paint as they can only be painted well with oil-based paints.

![]()

This process can help you change the color of your silicone hoses such as; a blue color or red color can be applied to the hose by using oil paints.

Oil-based paints stick very well to the silicone hose, which is why you need to roughen the silicone caulk first.

For this, you can use denatured alcohol, which will let your paint stick well on the silicone hose with shellac.

Denatured alcohol will act as a thinner for shellac-based paints that would allow a good catchy base for the hose.

After applying paint, you can wait 6 to 8 hours for it to get dried.

What Is A Silicone Hose Clamp?

A silicone hose clamp is a material or an item that helps to align the silicone hose and prevent it from shredding.

These clamps have an inside liner to protect the hose by covering the perforations.

These hoses have perforations in along inside a clamp that is helpful to adjust the diameter with a flat band for the clamp.

A type of clamp is the spring type clamp that is mostly used for clamping a hose that is fitted on a radiator of a vehicle.

Is Silicone Hose UV Resistant?

Silicone hoses have high resistance and flexibility, which also makes them highly resistant to extreme temperatures.

They have high resistance to UV Radiations as well as high temperatures and ozone too which is why these materials don’t degrade quickly upon their exposure.

This makes them certainly one of the best materials to be used under high temperatures in extreme engineering like aerospace applications and automobile manufacturing.

What Are The Quality Standards Followed By Chinese Silicone Hose Manufacturers?

The quality standards that Chinese silicone hose manufacturers like Baiwesilicone follow are:

- SO/TS16949:2002

- ISO/TS16949:2009

- ISO14001:2004

- OHSAS18001:2007

What Are The Steps Taken To Ensure The Quality Control For Silicone Hose Manufacturing?

The following steps are taken to ensure the quality control of silicone hose manufacturing:

![]()

- Visual inspection of standard HG/T 2185 for rubber hoses.

- Online Dimensional Control during the process of Calendaring through Sensors.

- Burst pressure at elevated temperatures.

- Online statistical process controls to measure the thickness and various characteristics.

- Time control and temperature management during Curing and Post-Curing of silicone hose.

- Life-cycle tests are maintaining temperatures up to 220 degrees inside and outside the hose.

- Tolerance and Dimensions hose standard GB/T9575.

- 100% Visual Inspection.

- Properties test for rubber hose.