Premier Rubber Washer Manufacturer

Biawe is a professional rubber washer manufacturer in China. We have more than 15 years of experience in the rubber product industry. Thousands of satisfied clients have proved our expertise from around the world. Here in Biawe, we are offering the best services to meet your requirements. Biawe can also supply you with the highest quality yet affordable rubber washers through our in-house production facilities. Choose Biawe as your trusted molded rubber parts, rubber bellow, rubber bumper, rubber gasket, rubber o rings, rubber grommet, rubber washer, supplier in China. Would you mind sending us your inquiries?

We manufacture Black Nylon Rubber Saddle Washers with 10mm, 13mm, 16mm, 19mm, 22mm, 25mm, and more diameter sizes. It is applicable for automotive industry applications.

We process Custom Design Rubber Washers through molding, injection, and cutting. It comes in different colors, such as black, red, and more.

Baiwe manufactures a durable EPDM Rubber Seal Washer with custom and standard sizes. It is helpful for different industries such as automotive, electronics, and more.

We produce Adhesive Tape Rubber Washer through die-cutting tools and compression molding. It is suitable for transportation, consumer products, and more applications.

These products are applicable for heavy industry, automotive, retail industry, mining, and more industries. We manufacture products using high-quality rubber materials like EPDM, Silicone, and more.

Baiwe offers Rubber Bonded Washer with different thicknesses. The suitable thread size for our Rubber Bonded Washer includes m10, m20, 3/8”, and 7/16”.

Our Neoprene Flat Rubber Washer features waterproof, oil-proof, and high-temperature resistance. We process Neoprene Flat Rubber Washer through injection, molding, and cutting.

Biawe is a professional manufacturer of Roof Screws Rubber Washer with high durability and excellent performance. It has various surface treatments to enhance functionality.

These products are plain, flat, sealing, and cushioning washer type. It comes with different thread sizes and thicknesses to suit specific applications.

We offer a wide range of Rubber Flat Tap Washers useful for plumbing, automotive, and other applications. It is customizable based on your requirements.

Biawe offers the highest quality O-Ring Seal Washer. These products feature waterproof, good sealing performance, and dust-proof properties.

Our Rubber Seal Cone Washer is suitable for faucet installation. We manufacture Rubber Seal Cone Washer using Silicone, EPDM, and other high-quality rubber materials.

Biawe: Expert Rubber Washer Manufacturer in China

Biawe is a leading rubber washer manufacturer in China for more than 15 years. We use advanced technology and production options to manufacture your rubber washer orders. Thus, we can provide you rubber washer with different colors, shapes, and size variations.

As a reliable manufacturer in China, we can provide you the best quality products at an affordable price. Biawe is your one-stop solution for your rubber washer needs. Please send us your inquiries today!

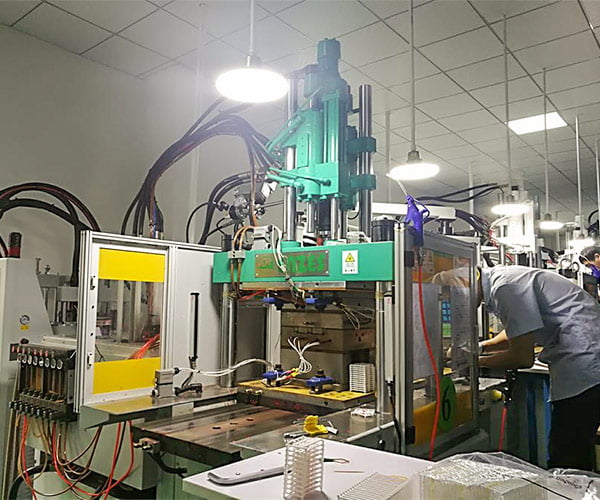

- Manufacturing

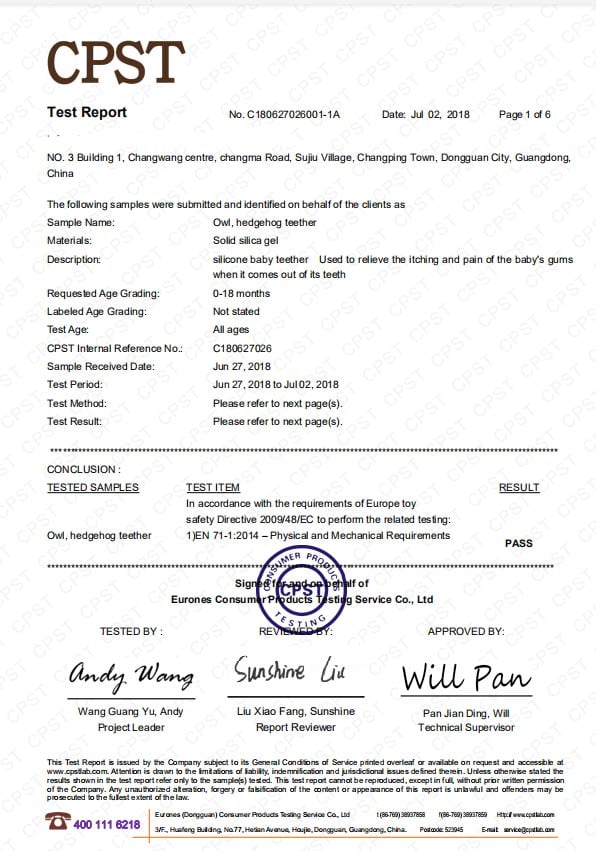

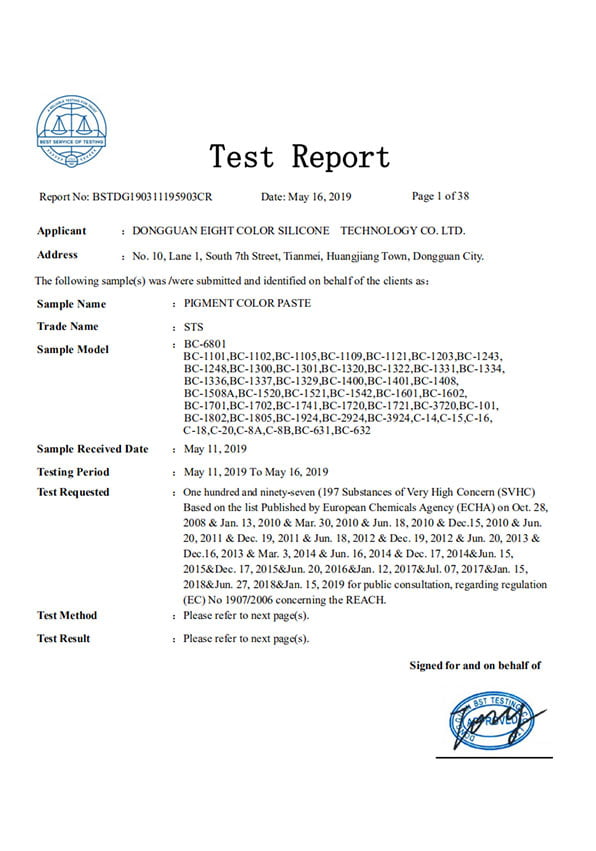

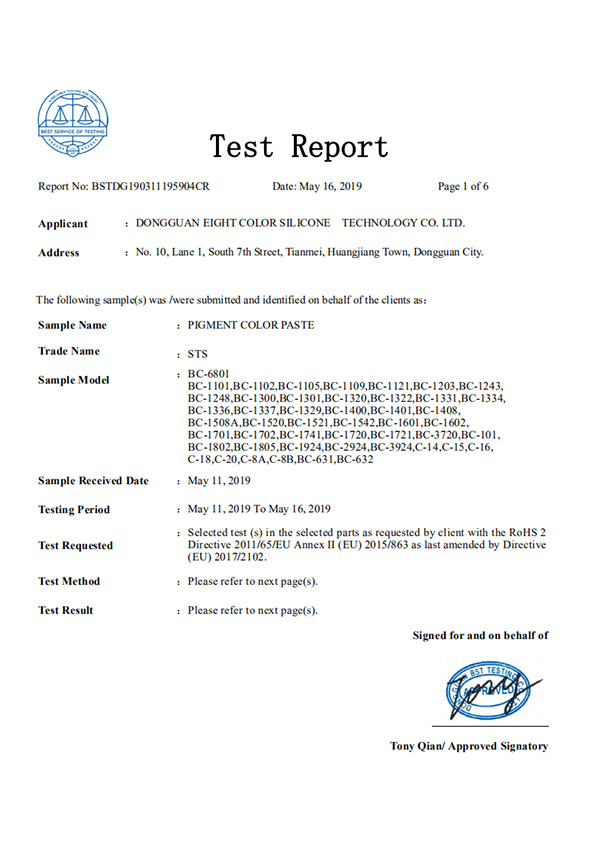

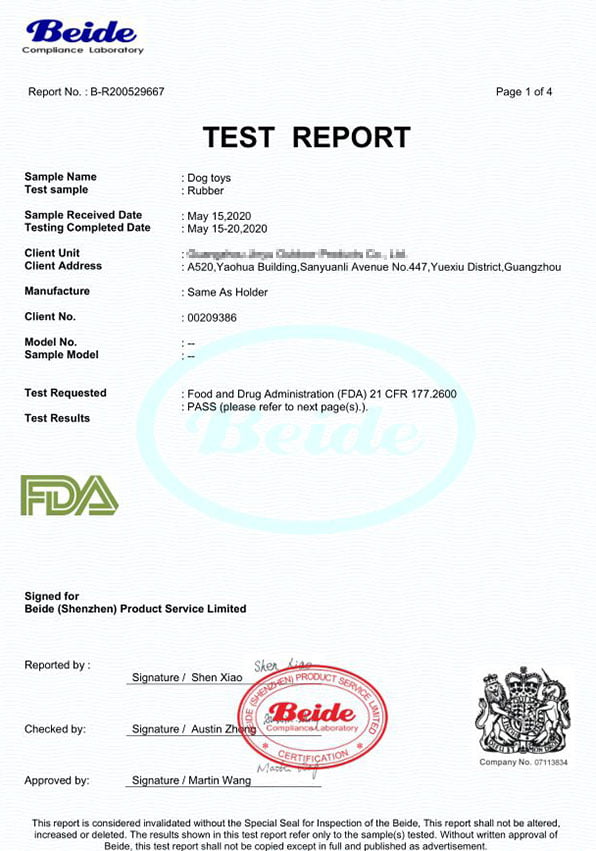

- Certifications

- Top Quality Control

Your Professional Rubber Washer Manufacturer in China

Baiwe is a trusted rubber washer manufacturer in China. We offer exceptional quality rubber washers at a reasonable price. With our total dedication to providing quality and commitment, we popular as the leading manufacturer in China.

We offer a wide range of rubber washers such as silicone rubber washers, EPDM rubber washers, and Neoprene rubber washers. You can purchase standard and custom-made rubber washers at Baiwe for your specific applications.

Our engineer’s design rubber washers that function as flat rubber that has a center hole. Thus, it can accommodate fluids and fasteners to pass. All our rubber washer products feature flexibility and durability to provide a tighter seal.

Baiwe also manufactures rubber washers that can absorb shock for applications with moving parts. Aside from that, we also design rubber washers with non-abrasive properties to assure you of scratch-proof quality. Thus, your rubber washers will last a lifetime.

The primary function of rubber washers is to prevent leakage. It can also dampen vibration and protect the surface. On the other hand, you can also use it to insulate against electrical charges for thermal and electrical applications.

Mostly, rubber washers are helpful in construction, aerospace, automotive, appliances, plumbing, and other industries. These are also common in ventilation, heating, air conditioner systems, boats, pools, aquatic products, and more.

Biawe is a leading rubber washer manufacturer in China for more than 15 years. Here in Biawe, we are offering the best services to meet your requirements. Choose Biawe as your trusted rubber washer manufacturer and supplier for your business. Biawe offers premium quality products, low-cost, on-time delivery, fast lead time, factory prices, and excellent services.

Make Biawe your primary silicone rubber products from China. Please send us your inquiries today!

Rubber Washer – Ultimate FAQs Guide

Are you in need of an efficient rubber washer supplier? Not sure which one you should opt for?

We are presenting a foolproof guide to help you select the best rubber washer supplier in China.

By reading this article until the end, you’ll have all essential information that will help you choose the right manufacturer.

Let’s drive straight into it.

- What Is Rubber Washer?

- What Are The Applications Of Rubber Washer?

- What Are The Benefits Of Rubber Washer?

- How Long Will Rubber Washer Last?

- How Are Rubber Washers Manufactured?

- What Are The Different Material Used In Rubber Washers?

- Are Silicone Washers Better Than Rubber?

- What Sizes Do Rubber Washers Come In?

- Which Is Better Vinyl Or Rubber Hose Washers?

- How Do You Measure Rubber Washers?

- Are Rubber Washers Waterproof?

- What Is The Difference Between A Washer And A Gasket?

- Do You Need Any Lubrication For Rubber Washers?

- What Is The Process Of Ordering Custom Rubber Washers From China?

- What Is The Minimum Quantity To Order Rubber Washers From China?

What is a Rubber Washer?

A rubber washer is a flat, round hardware tool often placed between the nut or screw to increase the tension.

Mainly it is made up of rubber and is helpful in applications that require tight sealing.

Generally, these are used in machines and applications with high exposure to water or other liquids or areas with high humidity.

Technically, the washer consists of a hole that is passed through the center of the materials.

For tight and robust stability, the entire diameter of the rubber washer must be greater than the diameter of the screw head or other hardware placed on it.

Similarly, the internal diameter of the washer should be lesser than the screw or nut head to ensure tightness and security of the system.

If all the requirements are not met adequately, the washer will not be stable at its place and will not provide stability to the applications.

Typically, the rubber washers are used in wet conditions due to their resistance against fluids and durability.

Due to their characteristic properties, rubber washers are frequently used in plumbing, ventilation, and air conditioning systems.

Commonly, the manufacturing of boats, pressure washers, swimming pools, and other related tools also uses rubber washers.

Another beneficial aspect of using rubber washers is protecting the applications from expanding or contracting under particular conditions.

Thus, it is beneficial in increasing life and protecting them from quick deterioration.

![]()

What are the Applications of Rubber Washer?

The applications of rubber washers are broadly distributed among various industries. Some of them are listed below:

1. Automotive Industry

Aircraft machines, motors, fastening for satellites, fuel pumps, robotic devices, and equipment uses rubber washers to enhance efficiency.

2. Electrical Industry

Usually, the rubber washers are used in circuit boards for insulating the device connections from vibrational effects.

Furthermore, various electrical charging units require rubber washers for tightening fluid leakage and preventing unnecessary electrical flow.

3. Heavy Machinery

Rubber washers are frequently used in heavy machinery conveyor belts to seal machinery processes, prevent oil leakages, and mitigate the vibrational effects.

Moreover, these rubber washers help maintain the sensor system of heavy machines, like keeping consistent fluid and air pressure.

Also, rubber washers play a vital role in tightening and sealing the bolts and screws to ensure long-term efficiency.

4. Household Appliances

Technically, many house objects require tight sealings to prevent damages, such as sealing drainage systems, preventing leakages under kitchen sinks, etc.

5. Medical Industry

Many critical medical devices require the use of rubber washers to facilitate patients for reliable medical processes.

6. HVAC Systems

Several HVAC cooling systems, including refrigerators, air conditioners, and water dispensers, use rubber washers to prevent leakages and dust particles in the system.

What are the Benefits of Rubber Washers?

The benefits of rubber washers are listed below:

1. Distribution of Weight

In the absence of a washer, the entire weight of a machine will be held on a small head of the screw or nut.

Thus, increasing the risk of a system being collapsed or expanded stress on a single point.

With the help of rubber washers, the weight and pressure are equally distributed in all directions hence reducing the stress.

2. Waterproofing

Due to high water resistance and vibrational resistance properties, the rubber washers prevent the systems from leakages and minimize the effects of vibrational shocks.

To that end, it is beneficial to increase life and to maintain the machine standards.

3. Flexibility

Rubber washers are more pliable and flexible as compared to metal and plastics.

With these properties, they offer a smooth fit and intense tightness over a wide range of screws and bolts.

![]()

How Long Will Rubber Washer Last?

Rubber washer lasts from three to five years, depending how they are use and maintained under certain conditions.

However, if you want rubber washers lasts more than 5-6 years, then it is better to buy efficient quality from leading manufacturers.

For example, purchasing high performance rubber washers from Baiwesilicone will enable your rubber washer lasts more than 6 years.

Consequently, they acquire about where you want to use the product and guide you with the most effective one.

Additionally, the quality of the rubber washers used by baiwesilicone is topnotch and gives effective outcomes for years.

Besides, prolonged performance of washer is also affected by the proper installation of the material.

How are Rubber Washers Manufactured?

Rubber washers are manufactured by the injection and compression of rubber using the rubber molding technique.

Technically, rubber molding is a process in which molten material is intended in a cavity to shape the rubber washer.

The raw rubber sheets are initially collected in a liquid state, which is then introduced in the molding cavity.

In the case of manufacturing rubber washers, the cavity used is about the size of the external diameter.

Therefore, when the molding cavity is filled with molten rubber, it attains the desired size and shape.

When the rubber is cooled in the cavity, it hardens and forms the rubber washer.

Typically, the customized rubber washers are prepared according to the customer’s needs or application requirements.

Both injection molding and compression molding techniques are widely used for the manufacturing of rubber washers.

Preferably, the injection molding method is used for efficient and uniform manufacturing of multiple rubber washers.

Usually, the rubber washers are manufactured with varying degrees of softness and hardness.

Typically, these washers have a softness of approximately 30 and hardness of about 90, with the thickness ranging from 0.031 inches to 0.375 inches.

All the rubber washers are made with excellent tensile strength and abrasion resistance properties.

What are the Different Materials Used in Rubber Washers?

The different materials used in rubber washers are available with variable compositions.

Indeed, every application has distinctive requirements. Following are the details about the chemical substances used for rubber washers.

1. Silicone Washers

Silicone is a prime choice of many manufacturers due to its extreme withstanding against elevated temperatures, whether hotter or colder.

Additionally, the silicone is operational in dry and humid conditions with solid resistance against fungus and UV light.

2. Ethylene Propylene Diene Monomer (EPDM)

EPDM is known for manufacturing rubber washers because of its high-temperature protection and against several harmful elements.

These include ozone rays, steam, alcohols, water, brake fluids, along with low permeability of other elements.

Due to the presence of dielectric ions, the EPDM provides extra protection against electrical current.

Furthermore, all the EPDM products are heat resistant and have persistent colors.

3. Neoprene

Another efficient material used for the manufacturing of rubber washers is Neoprene.

Consequently, they work well in the hotter atmosphere and resists the presence of solvents, petroleum, and oils.

Commonly, Neoprene is used in general elastomeric applications because of its protection against freons, milder acids, and high-aniline oils.

![]()

Are Silicone Washers Better Than Rubber Washers?

Whether silicone washers are better than rubber washers or not, it can be identified by analyzing the characteristics and properties.

Generally, the rubber washers possess high tensile strength, abrasion protection, and tear strength, while silicone has lesser compatibility against these conditions.

Furthermore, rubber washers are capable of resisting the temperatures from -50°C-80°C while silicone washers can bear temperatures -50°C-230°C.

Typically, the rubber washers are compatible with cold, hot water, alcohols, aldehydes, ketones, and weak acids.

On the contrary, silicone washers can resist saltwater, chlorinated water, and hydraulic fluids.

Additionally, the rubber washers possess a tensile strength of up to 25 MPa, while silicone washers have a tensile strength of about 5 MPa.

Moreover, rubber washers are widely used in applications, including conveyor belts and tyre threads.

On the other hand, silicone washers take part in applications less prone to abrasion and tearing.

What Sizes Do Rubber Washers Come in?

Rubber washers come in a variety of sizes, dimensions, and thicknesses to tighten the screws and nuts and secure the efficiency of the applications.

Though, rubber washers can be customized according to the needs and requirements of the industries.

Commonly, the following rubber washer sizes are used in various applications:

16. M2

Typically, M2 is the smallest rubber washer size with an internal diameter close to 2.1mm, outer diameter 4.4, and thickness of about 0.5mm.

17. M3

M3 is the rubber washer with an internal diameter of 3.1mm and an external diameter of 6.2, while the thickness of the washer is 0.8mm.

18. M4

Rubber washers with an inside diameter of 4.1mm, an outer diameter of 7.6mm, and a thickness of 0.9mm are named M4.

19. M6

M6 rubber washer has an internal diameter of 6.1mm, an exterior diameter of 11.8, and a thickness of 1.6mm.

20. M8

Rubber washers named ‘M8’ have diameters of 8.1mm and 14.8 (internal and external respectively) and have thickness close to 2mm.

21. M10

Generally, M10 rubber washers have an internal diameter of 10.2mm, external diameter of 18.1mm, and a depth is about 2.2mm.

22. M12

With a thickness of 2.5mm, inner diam 12.2mm, and external diam 21.1mm, M12 rubber washers are also available on the market.

23. M14

M14 has diameters of 14.2mm and 24.1mm (interior and exterior) with a thickness of 3mm.

Which is Better: Vinyl or Rubber Hose Washers?

Opting for vinyl or rubber hose washers is entirely dependent on how far each resistance property works.

For instance, rubber hose washers are the most durable and reliable choice for any use, while vinyl washers’ working efficiency is limited.

Due to the reinforcement of rubber washers with nylon tire cords can withstand the toughest water exposures, both hot and cold.

On the contrary, vinyl hose washers are prone to cracking and less resistant against kinks.

Furthermore, rubber washers are more resistant and protected under extreme weather conditions, both hot and cold.

On the other hand, vinyl hose washers are relatively less resistant.

Rubber washers cannot be stored in direct sunlight since they easily get damaged from UV radiation.

While vinyl washers can be stored wherever you like without the fear of them being damaged.

Consequently, rubber washers weigh more than vinyl washers, making them stable and firm at their places, thus providing extra tightness and firmness.

How Do You Measure Rubber Washers?

You can measure rubber washers using standard techniques to have a clear idea of which washer will best suit you.

Certainly, rubber washers are used to fasten the screw or increase the nut area to provide extra clamping surface and more tight sealing.

Typically, the washer size is determined by the minimal hole diameter, i.e., the internal hole of the washer.

Moreover, the washer size depends entirely on the head screw; thus, the higher the screw head, the higher the washer size.

For example, Fender washers have larger outer diameters (OD) to cover a wide area on the surface, making it an efficient choice for irregular or oversized holes.

Similarly, machine screw washers are the smallest washers with an external diameter just twice as the internal one to fit in smaller holes.

However, there are mega thick washers with an extra thickness which are helpful for spacing applications.

Thick flat washers help occupy spaces in a spacing application. Due to their high thickness, they fit in the empty areas.

![]()

Are Rubber Washers Waterproof?

Rubber washers are waterproof flat piece hardware sealings, typically used in applications that are exposed to water or other liquids.

Consequently, they are more frequently used in humid environments since they have anti-rust properties.

Due to their durability and resistance to fluids, rubber washers are used in plumbing and other applications involving continuous moisture and humidity.

Additionally, the rubber washers are also used in systems experiencing condensations such as Ventilation, HVAC Air Conditioning, and Heating.

They are commonly used in ships, swimming pools, boats, submarines, and other water-based equipment.

Furthermore, the waterproofing property of rubber washers makes the application resistant against slight expansion and contraction.

Since rubber washers protect the system from moisture inhibiting the potential exposure, which increases the system’s efficiency.

However, rubber washers may deteriorate with time, but they are strong enough to last longer if they are tightened regularly.

Moreover, it must be noted that rubber washers must not be used with corrosive liquids as they can react with them negatively.

![]()

What is the Difference Between a Washer and A Gasket?

Often, the difference between a washer and a gasket is forgotten. Both terms are used in interchangeable meanings.

However, many factors distinguish one from another, like washers are a disc-shaped hardware substance typically used to tighten the bolt.

While gasket is a sealant used on the joint of two substances to avoid any chance of leakage.

Typically, a bolt is passed through a hole in a washer which is twisted to fit in the position and tighten the surface.

On the other hand, the gasket allows the oil, air, gases, and other liquids to pass through it while preventing leakage.

Usually, the washers are available in circular shape due to use with bolts, nuts, and screws.

On the contrary, gaskets are not used with screws, so they are available in various shapes and sizes.

Common types of washers are:

- Plain Washers

- Wedge Lock Washers

- Spring Washers

- Tab Washers

- Locking Washers

- Cupped Washers

- Torque Washers

- Toothed Washers

Commonly known types of gaskets are:

- Flange Gasket

- Spiral-Wound Gasket

- Constant Seating Gasket

- Soft-Cut Gasket

Do You Need Lubrication for Rubber Washers?

Lubrication for rubber washers is necessary to enhance the productivity and efficiency of the entire system.

Usually, the rubber washers are made up of Nitrile, Neoprene, and EPDM that require lubrication to boost the performance.

Though natural rubber washers don’t require the use of lubricant, it isn’t easy to analyze whether you have synthetic rubber or natural rubber.

To the end, always use a silicone-based lubricant to protect the application and increase the washers’ lifespan

Usually, the swimmers and snorkelers use rubber washers with lubricants to seal their flashlights and camera cases for underwater swimming operations.

Moreover, tinkerers and watchmakers put lubricated rubber washers to mend their watches and prevent them from tearing.

Commonly, plumbing tasks use greased rubber washers to keep the faucets and water filters sealed and tightened.

Moreover, many leading Chinese companies, including Baiwesilicone, prefer manufacturing hose connections with lubricated washers.

It is because of its increased advantages for repairing and long-term protection against damage.

For the lubrication of rubber washers used in the food industry, always use food-grade lubricants that are approved and safe when in contact with food.

What is The Process of Ordering Custom Rubber Washers from China?

The process of ordering custom rubber washers from China is simple and doesn’t require any detailed processing.

Many Chinese manufacturers such as Baiwesilicone supply customized premium quality rubber washers at affordable rates.

Furthermore, their experienced engineers keep the large rubber sheets in stock to cope up with the urgent requirements of consumers.

Additionally, the company is capable of producing in-house bulk orders in different shapes and sizes.

Moreover, the rubber sheets are stored and kept ready to be punched or cut according to the sizes.

Consequently, you have to place an order, and their skilled team members will start working on it.

With multiple cutting technologies, they can quickly produce standard as well as customized rubber washers.

For your ease, contact their service providers to get detailed information about the products and place an order for customized products.

They can also send you samples of rubber washers and offer minimum ordering packages and discounts for you.

What is the Minimum Quantity to Order Rubber Washers from China?

The minimum quantity to order rubber washers from China varies depending on the product type, quantity, and quality.

Normally, a leading rubber washers’ supplier in China, Baiwesilicone, requires a minimum of 500 pieces or 1000 pieces.

Regardless of the quantity of your order, you are a valuable client to the company and, therefore, receive the quality product every time.

At baiwesilicone, a team of professionals starts working soon after you purchase an order to deliver your product within 15 to 25 days.

Consequently, the material you will choose for your product passes through a series of quality control systems.

All the items are dispatched from the company once they are 100% perfect and ready for third-party inspection as well.

Baiwesilicone never disappoints its consumers for selecting them for the services.