Expert Rubber Seal Manufacturer and Factory

Baiwe is China’s leading high-quality rubber seal manufacturer. We offer different types of rubber seals for your business. Thus, Baiwe can provide a total solution for your needs. We also provide OEM and ODM services to customize your rubber seals. Besides, Baiwe has complete production technology and state-of-the-art facilities. We also do thorough inspections and testing before shipment. Therefore, you can guarantee high-quality and defect-free products. Please send us your inquiries today!

Baiwe is a trusted Custom-made Rubber Seal Manufacturer. We manufacture products using NBR materials. It is applicable for vehicles, toys, and other usage.

We offer a Hydraulic Rubber Piston seal that features a good sealing effect, easy installation, extrusion resistance, and excellent operating conditions.

We manufacture all kinds of Rubber Oil Seal. This product features different colors such as black, copper, bronze, and more.

Baiwe offers NBR Rubber Skeleton Oil Seal that is suitable for isolating parts that require lubrication. We manufacture NBR Rubber Skeleton Oil Seal using high-quality nitrile rubber.

We offer Windshield Rubber Rear Gasket Seal with high-temperature resistance and excellent heat resistance. These products are also environmentally friendly.

Our EPDM Rubber Seals Strip comes in various colors like black, red, yellow, green, and more. We process EPDM rubber seals strips through rubber injection molding.

Our Automotive Rubber Seal features a mechanical seal style. It also has ≤0.5Mpa pressure and -40℃~125℃ working temperature range.

We manufacture Rubber Weather Protector Seal using EPDM, PVC, and other high-quality rubber materials. It features water resistance and acid resistance.

The strip shape of our EPDM Rubber Draught Seal is customizable based on your specification. It features anti-collision, moisture-proof, and flame retardant.

We manufacture a wide range of Rubber Seal O Ring. These are perfect for automotive, industrial, and commercial applications.

Our NBR O Ring Gasket Seal features 60℃~250℃ working temperature. It comes with a standard and customized design to meet your requirements.

We manufacture a wide range of Shaft Oil Seal Rubber. Baiwe offers products at a competitive price, premium quality, and cost-effectiveness.

Baiwe: Your Expert Rubber Seal Manufacturer in China

Biawe has more than 15 years of experience in manufacturing the highest quality rubber seal. Our expertise in this field makes us the leading rubber seal manufacturer in China. We aim to support your business by providing excellent quality products, professional services, great deals, and affordable prices.

We serve thousands of customers from over 60 countries around the world. Baiwe looks forward to working with you. Please submit your request today!

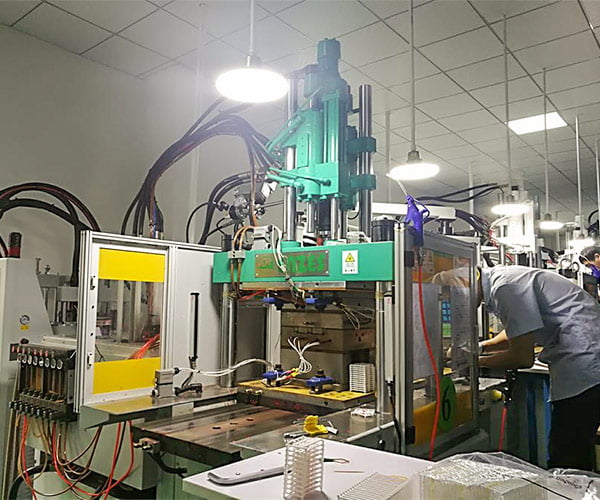

- Manufacturing

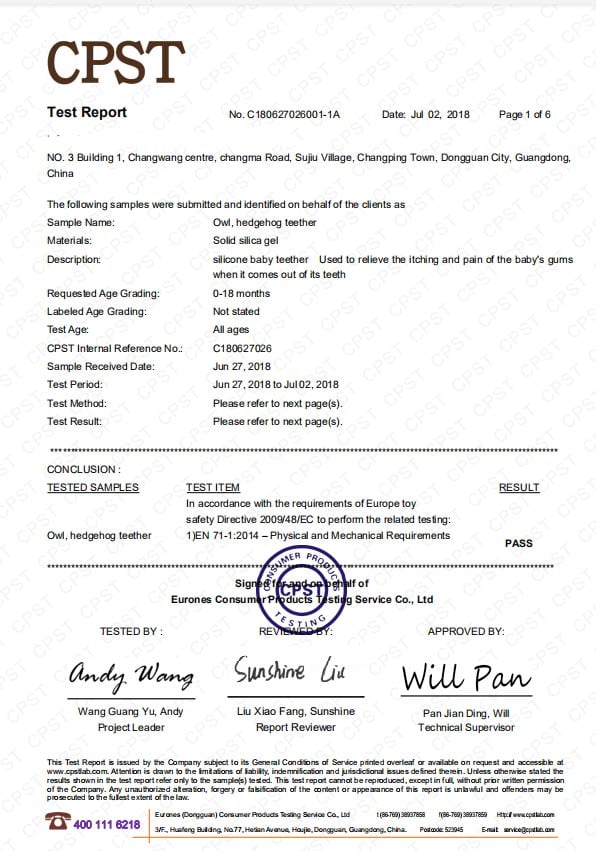

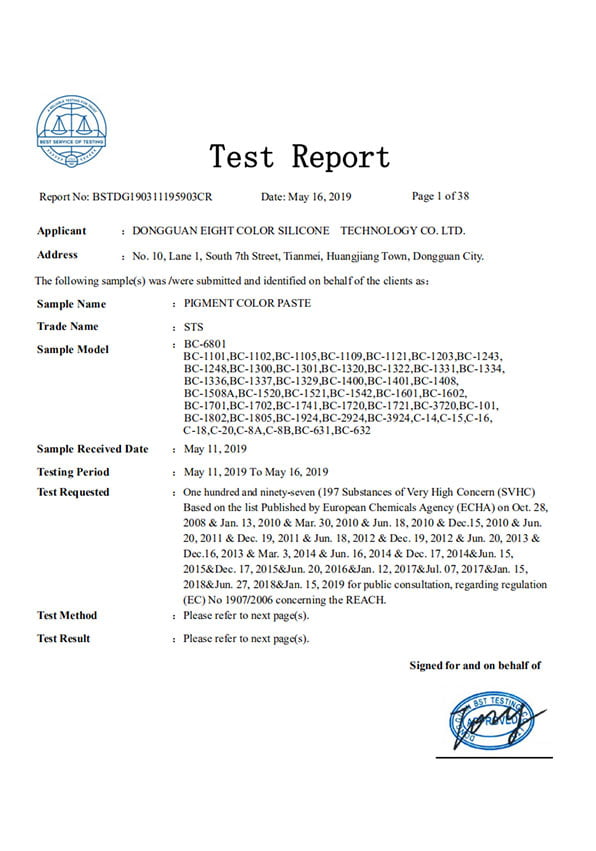

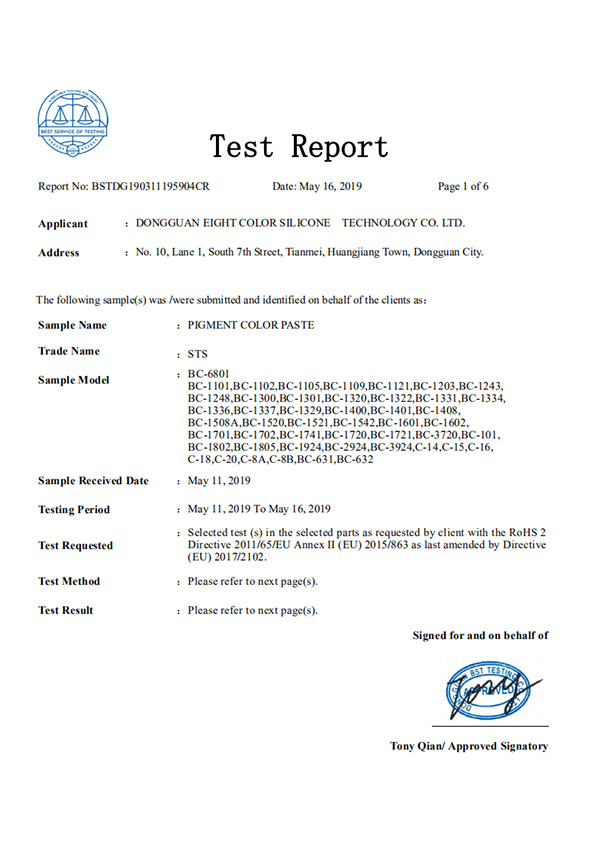

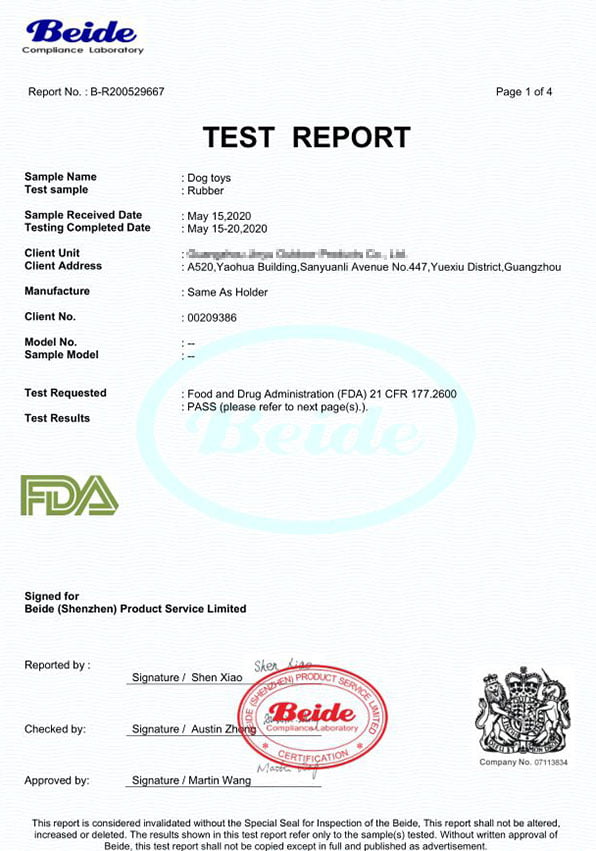

- Certifications

- Top Quality Control

Your Reliable Rubber Seal Manufacturer in China

Baiwe is a professional rubber seal manufacturer in China. We have more than 15 years of experience in rubber seal production. As a professional manufacturer, our goal is to provide customers with the best purchasing experience.

We manufacture limitless rubber seal designs. You can purchase our Hydraulic Rubber Piston seal, Rubber Oil Seal, NBR Rubber Skeleton Oil Seal, Windshield Rubber Rear Gasket Seal, EPDM Rubber Seals Strips, Automotive Rubber Seal, and more.

Baiwe produces all our products through excellent production methods. We also use state-of-the-art manufacturing facilities and advanced technology to provide you an exceptional solution. Therefore, Baiwe can always satisfy your needs.

Baiwe is also an OEM rubber seal manufacturer. We offer custom-made products based on your exact specifications. If you purchase from us, we can incorporate your logo upon your request. Just send us your drawings, specifications, and details.

We manufacture different rubber seals, including lid seals, ribbed profiles, triangle sections, co-extruded pedestals with sponge rubber bulbs, and more. You can use Baiwe rubber seals for sound enclosures, heavy machinery, tonneau covers, and more applications.

Our rubber seals are your perfect solution for protecting your vehicle, drowning out noise, or eliminating vibration. We have a wide range of rubber seals for doors, windows, garages, trims, and more. Here in Baiwe, we have complete dedication to helping you find suitable rubber seals for your business and projects.

Baiwe specializes in the design, development, and production of rubber seals. We manufacture precision rubber seals through extruding and molding methods. Our diverse range of rubber compounds allows us to manufacture the highest quality rubber seals.

For more than 15 years, Baiwe has been the most trusted rubber seal manufacturer in China. We offer competitive prices, high-quality products, excellent services, and after-sale services, and on-time delivery. Small quantities and bulk orders of rubber seal are both welcome. Contact us for more information. We will cater to your needs immediately.

Choose Baiwe as your no.1 rubber seal manufacturer. Send your inquiries today!

Rubber Seal – Ultimate FAQs Guide

Rubber seals are essential parts in equipment and act as connectors between joint components. The following is a detailed guide to rubber seals and their roles in different industries.

This guide will answer frequently asked questions that detail essential information about rubber seals, their functions, their uses, and their manufacturing.

- What Is A Rubber Seal?

- What Are The Applications Of Rubber Seal?

- What Are The Benefits Of Rubber Seal?

- How Long Will Rubber Seal Last?

- How Are Rubber Seals Manufactured?

- What Material Is Used For Rubber Seals?

- How Does Rubber Seal Work?

- Is A Gasket And A Seal The Same Thing?

- Is Vaseline Good For Rubber Seals?

- What Is The Best Lubricant For Rubber Seals?

- What Are The Different Types Of Rubber Seals Available?

- What Are The Designing Guidelines For Rubber Seals?

- What Quality Certifications Do Chinese Rubber Seal Manufacturers Have?

- What Is The Quality Of Chinese Rubber Seals?

1. What Is A Rubber Seal?

Rubber seals are tools used in equipment that stop gases or liquids from leaking out of a particular container or set of equipment.

They are used to prevent leakage of lubricants in precision bearings and machines.

The mechanical function of a rubber seal is to act as a lubricating barrier between the stationary and moving parts of a machine or a piece of equipment.

The seals help provide lubrication and stop friction damage in machines while stopping potential spillage and contamination.

Rubber seals are also called oil seals and rubber gaskets, so named because they target oil leakages and prevent corrosion in equipment from moisture, humidity, and other environmental factors.

The seals are often made for different purposes and can be made for pipes, valves, bearings, or other gaps and openings in any part of an equipment or machine.

Oil seals are especially needed for machines with oil in them as an added safety feature because any oil leaks could be a potential fire or environmental hazard.

Rubber seals are available in the market in many shapes, sizes, and capacities.

The predominant types of rubber seals in the market are U ring seals, bulb trim seals, O ring seals, bulb seals, accordion seals, and lip seals.

2. What Are The Applications Of Rubber Seals?

![]()

The applications of rubber seals vary according to the type industry, product, equipment, or rubber material.

Here are some examples of the main applications of rubber seals.

- Food Storage

Different types of rubber materials have different advantages in particular industries.

For instance, the food industry uses rubber seals to seal the lids, caps, or tops of jars and containers of food.

The rubber seals work well to provide air tight containers that do not let the food get contaminated.

The food storage industry also uses rubber seals, particularly silicone rubber seals, for their temperature control.

In fact, silicone seals are often used in refrigeration of food products for two main reasons.

The first reason is that silicone is devoid of carbon, a particular concern in food safety, and the second reason is silicone’s capacity of being an insulator and a freezer sealant.

- Vehicles

The automobile and aeronautical industries both depend on rubber seals to maintain the integrity of key equipment and to prevent leakage in oil-based mechanical parts as well as ensure air and temperature regulation.

Car doors use rubber seals to keep in air conditioning and heating and to avoid damage from the elements.

Further, engine parts in cars have nitrile rubber sealing to keep oil inside.

Nitrile seals are particularly useful in transport vehicles because of their temperature resistance.

Rubber seals also create vacuums to provide optimal conditions for airplanes.

For instance, aeronautical engineers use rubber seals on doors for the cabin to be pressurized and for plane to be able to rise up to high altitude levels.

Airplane electrical systems also depend on silicone or natural rubber seals or gaskets because they regulate temperature or avoid wear and tear.

- Electronics

Electronic devices and machines, including household devices, often use rubber seals to create vacuums and seal in air or lubricants from the outside.

Rubber seals and different grades of rubber are often needed as safety features in household equipment.

It gives the equipment an International Protection Rating and make the equipment suitable for regular use for all ages and types of people.

Natural rubber is often deployed in household machines because of the material durability and elasticity.

Silicone and natural rubber are the main seals in most equipment to provide problems of wear and tear, electrocution, and environmental damage.

3. What Are The Benefits Of Rubber Seals?

Rubber seals have varied functions and as a result have various benefits. The following is a list of important benefits provided by rubber seals.

- Durability

Rubber seals top the list for durable materials and are used in airplane’s because of their ability to absorb and even out pressures and forces applied to the seals.

Rubber seals are also known for their ability to avoid damage and corrosion.

In addition to their own durability, rubber materials also extend the lifetimes of the equipment they cover.

Rubber seals’ non-toxic, odor-free, and leakage-free properties allow the equipment to not get damaged by chemical reactions or weathering.

Silicone rubber seals can actually be extremely safe materials especially because they can withstand multiple sterilization processes.

- Flexibility

Rubber seal materials are used because of their flexibility, often to imitate the shape of the lids, openings or grooves they need to cover.

Rubber manufacturers like Baiwesilicone make sure that the seals are properly shaped for coverings.

Because a rubber seal is also a freezing sealant, its temperature endurance makes it a good material for low or freezing temperatures.

Since the rubber material remains flexible at very low temperature points.

- Insulation

Temperature resistance is one of rubber’s greatest strengths.

Silicone rubber materials can especially work well in extreme temperature ranges with a maximum temperature endurance of 310°C and a minimum temperature resistance of -100°C.

Rubber seals are therefore excellent for extremely hot or cold temperatures and are lauded for their versatility and endurance.

Seals can increase their temperature resistance, malleability, strength, and durability if they are also mixed with other materials.

Silicone rubber can even endure heat sterilization processes.

Once silicone seals are sterilized with methods like heat sterilization, gamma radiation or steam autoclaving, the silicone rubber seals can even be used in medical equipment.

![]()

4. How Long Will Rubber Seals Last?

Depending on the quality or type of rubber, seals can last up to 5 years. The best quality of rubber materials will go up to 20 years.

Natural rubber seals, for instance, can go for around 3 till 5 years. Nitrile, Butyl, and Neoprene rubber seals will last for 5 till 10 years.

It is Silicone rubber, however, that will last the longest time with a 20-year shelf life.

The longevity of a seal’s shelf life depends on the quality and type of rubber as well as the conditions in which the rubber is kept.

High quality silicone rubber, like the one provided by Baiwesilicone, happens to have a higher endurance and lifespan.

Rubber seals should be stored in optimal environments that have temperatures of 38° C or below and humidity levels of 75% or below.

Further, rubber should always be kept away from direct sunlight and ozone-generators like air purification systems.

Sometimes rubber gaskets can get damaged as they age or they can deteriorate faster as a result of their quality.

Furthermore, rubber itself is a material that can dry, get cracks, or get environmental damage overtime.

As a result, it will need replacement or repairs once in a while.

However, most rubber seals or gaskets are designed for longer periods and as components of essential systems like airplane wiring.

If a gasket happens to corrode or age, they can be fixed with tools by a maintenance staff or engineer.

5. How Are Rubber Seals Manufactured?

Rubber seal manufacturing starts with taking raw materials of uncured rubber and running it through a die while adding heat and pressure to the process.

Next, vulcanization, or heating, takes place to cure the rubber material and mold, reshape, or further process the cured rubber.

The extruded rubber from this process is forced to harden at any level between 40 and 90 durometers and reshaped into different components and shapes, like rubber tubing, gaskets, or round seals.

Manufacturing rubber seals also involves further grinding, drilling, milling, and processing the extruded rubber via different means.

Punching, for instance, is a method that requires bending rubber with the Rule Forme, or steel strip, and a hydraulic press that reshape rubber into the desired gasket, seal, or reels.

Water jet cutting, laser cutting, and hand cutting are three other methods of seal manufacturing.

The water jet method involves high pressure water to be forced through a sheet of raw material to shape the rubber.

Laser cutting uses a laser instead of water and hand cutting involves cutting and marking the rubber by hand or with knives or saddle punches.

![]()

6. Which Material Is Used For Rubber Seals?

Rubber seals and gaskets are made from different materials and for different purposes. Here are some examples of prominent rubber materials.

- Nitrile Rubber

Nitrile rubber seals are used for fuel tanks and automobiles.

They are made from a synthetic nitrile rubber material that can withstand temperature ranges of -40°C to 121°C and have a durometer level of 70.

They are useful for leakage prevention and chemical corrosion resistance.

- Silicone Rubber

Silicone rubber seals are used for multiple high-grade materials including medical equipment, equipment for the food industry, electronic devices, and automobiles and airplanes.

They endure temperature ranges of -60°C to 232°C and an average durometer level of 70.

Silicone rubber seals are known for their resistance to UV rays, ozone effects, environmental damage, and extreme temperature resistance.

- Neoprene Rubber

A Neoprene rubber seal is used in air conditioners and refrigerators because of their ability to withstand cold temperatures.

It manage heat and weather resistance, and have ability to prevent friction, corrosion, and abrasion.

The rubber seals can operate at extreme temperature ranges of -43° and 107°C and their durometer levels range between 40 and 90.

- EPDM Rubber

EPDM rubber is also a common material for rubber selas that allows chemical and heat resistance in medical equipment, automobiles, electronic devices, and appliances.

They have a durometer range of 40 till 90 durometer and have a temperature range of -51° till 150°C.

7. How Does A Rubber Seal Work?

Rubber seals work to prevent leakages of lubricants and gases from machinery and to prevent external elements from damaging the inside of the machines.

Rubber seals like O-rings are usually placed between two components in high-pressure devices.

Rubber seals are put into a channel or the indent of a groove between two parts of a machine that are to be linked, joined, or pushed together.

This could refer to components of an engine or the lid of a jar.

Because rubber is an elastomer, it allows elasticity and flexibility in joining and separating the components as well as allowing the spaces between them to become air-tight and chemically resistant.

As the name suggests, rubber seals then seal the components with a sealing force.

The seal would, however, require a balance between the internal and external pressure applied to the joints otherwise the seals can break.

8. Are A Gasket And A Seal The Same Thing?

Gaskets and seals are not entirely the same thing but they are similar.

Seals are the overall, broad category to which gaskets belong.

The seals category includes parts like O-ring seals and rubber gaskets, both used popularly in appliances, aeronautical and automobile industries.

The major difference between seals and gaskets is the fact that gaskets are used in static devices versus seals which are also used in mechanical and moving parts like engines and motors.

Seals are usually rounded and outfitted with rubber and metal inner and outer rings. Gaskets are similarly rings made through injection or compression rubber molding methods.

Gaskets and seals also have slightly different roles.

Seals are often used between rotating parts whereas gaskets become essential connectors for flanges and mechanical components with flat surfaces to avoid leakages.

9. Is Vaseline Good For Rubber Seals?

Vaseline, or petroleum jelly, is not a good lubricant for rubber seals.

It is actually an ill-advised move to use Vaseline on rubber because rubber or neoprene-based seals often damage or react with the petroleum components in Vaseline.

Rubber seals do often need lubrication to maximize their performance capacity however the lubricant must be carefully selected.

Most of the lubrication for rubber seals is done through silicone and Teflon lubricants because these materials are the least reactive.

Petroleum-based products like the Vaseline petroleum jelly often corrode all types of rubber equipment and devices.

They can also damage the structural integrity of the rubber products by causing wear and tear. Rubber can also get reshaped or stretched out if it reacts with Vaseline.

![]()

10. What Is The Best Lubricant For Rubber Seals?

The best types of lubricants for rubber seals depend on the stages of the seal’s shelf life.

The optimal lubricant for a rubber seal is silicone oil if the seal is being lubricated for a temporary period.

Molybdenum Disulfide and silicone oil are two of the lubricant types that can be used on rubber surfaces and function well as temporary coats for polymers and rubber seal assembly.

Both substances can be useful as temporary measures for lubrication however cannot be used for all materials.

The grainy Molybdenum Disulfide does not pair well with surfaces that need a smooth finish and silicone oil coatings react negatively to silicone-based rubber materials and seals.

PTFE coatings can be good semi-permanent measures for devices that need to be in top shape for functioning even though function at varying intervals, for instance fire safety systems.

For permanent measures, assemblers and engineers use chlorination for sealing internal lubricants and preventing abrasion in rubber seals.

This process is done to the surface of rubber seals and because of its permanent effects is called modification.

However, chlorination modification can only work with certain rubber seals because it can react negatively to materials like EPDM.

Rubber seals need lubrication at stages to prevent the seals from becoming ineffectual or to allow air compression systems to get lubricated as a whole.

It is important to understand the need for these lubricants at different stages. The reasons for lubrication are listed below:

- Rubber seals are lubricated to avoid friction, abrasion, and corrosion between joint parts.

- Rubber seal lubricants work to decrease breakaway pressure within the sealed components.

- Rubber seals are often placed in atmospheres that reduce lubrication’s exhaust in compressed air systems.

- Rubber seals require more lubrication because of insufficient initial lubrication.

11. What Are The Different Types Of Rubber Seals Available?

Seal types often depend on motion with static, dynamic, and rotary seals as the main categories of seals.

Each is so defined because of their lack of motion, slower motion or rotation, and high speed and dynamic movement, respectively.

The dynamic and rotary seal are differentiated through their speed of oscillation or rotation where the surface speeds for the dynamic seal must be below 50 fpm (15 meters/min) and higher for the rotary seal.

There are many different types of these rubber seals available in the market however the following are the major rubber seals.

- O-rings

O-rings are popular types of rubber seals and are regarded as flexible elastomer solutions for leakages in most every day and electronic equipment.

The O-ring, as the name suggests, is in the shape of an O or a torus and has a circular cross-section.

The elastomer is meant to be fitted into grooves or openings between joint components and to be compressed as a sealant to block liquid and gas leaks.

The O-ring is made to fit into the groove exactly so that the two joint components or surfaces remain intact.

- Accordion Seals

Accordion seals are made from extruded rubber and are so named because of their folds, folds that resemble an accordion instrument.

The seals have the ability to change shape through stretching and compression and they can protect vehicles from external contaminants and weather.

They are often made from EPDM rubber materials and sometimes have spring steel looms within their parts.

- Lip Seals

Lip seals are used in automobiles, motorized or electric pumps, mill equipment, engines for cars, and industrial equipment.

They have elastomeric compounds that can have varying levels of resistance to leakages, temperatures, and pressure.

The lip seal is so named because it usually has an opening and are placed on rotating shafts to act as a seal and avoid contamination of equipment.

- Bulb Seals

A bulb rubber seal is a round and open seal that sometimes come in moon or teardrop shapes and are constructed from sponge rubber material.

They are usually sealants between doors and are often used in the construction or automobile industries to reduce friction between a door frame and the door.

EPDM is often the material of choice for bulb seals to create tight seals for cars and buildings.

12. What Are The Designing Guidelines For Rubber Seals?

Rubber seals should not have complicated profiles and tool designs otherwise the costs will rise. However, the tools should be carefully selected for the method of seal production chosen and the requirements of the materials.

Sizing needs to be a major concern for designers and manufacturers to ensure proper dimensions and adequate axial compression with the cross-section of seals bigger than the gland depth.

All materials selected for rubber seals should be judged with respect to the environment they will exist in and the purpose they will serve.

Considerations like UV exposure, RF prerequisites, chemical compatibility, and temperature levels should all be considered.

- Seal Pressures

Rubber seals have pressure and forces acting upon them internally and externally.

This pressure, as well as environmental conditions that produces the pressure, should be kept in mind when designing and testing the strength and leakage prevention of a rubber seal.

If the seal is to be exposed to higher pressure environments, a soft rubber material should not be used.

Instead, rubber materials with higher levels of hardness and durometers should be included in relation to the temperature pressure ranges expected.

- Chemical Reactions

The seal’s material should be designed with consideration of the chemical compositions and compatibility of the seal itself as well as its complementing materials.

Other materials should be selected and applied to the seal with potential chemical reactions in mind.

For instance, silicone oil should not be used with silicone rubber.

- Temperature Changes

An environment’s temperature will have a physical and chemical effect on rubber seals so all of the seal materials should be selected with consideration of their expected temperature ranges.

If the seals cannot handle extreme temperatures, heat can harden the rubber and cold weather can cause the seals to shrink.

Both instances can cause leakage and problems in compression.

Compression, through heat, can cause the rubber to reshape and compression’s effect on the mating surfaces is yet another factor to be considered.

- Friction and Abrasion

Dynamic and rotary seals have movement and are therefore in danger of damage from friction and abrasion as a result of contact between their moving parts or mating surfaces.

What this phenomenon requires is cautious consideration of materials and lubrication to avoid lubricant and seal failure.

For instance, silicone or fluorosilicone should not be added to dynamic seals.

More movement in rotary seals can cause heat damage, seal expansion, and deformity of the seal as a result of the Joule effect of physics.

![]()

13. What Quality Certifications Do Chinese Rubber Seal Manufacturers Have?

Chinese rubber seal manufacturers like Baiwesilicone have multiple quality certifications and are approved by regulating authorities like the FDA, the SGS, and the LFGB.

As the company is a major exporter and producer of international silicone and rubber materials, including seals, it needs to follow safety and quality standards at an international level.

As such, they have to assure and properly label the International Protection Ratings of their rubber seal products.

For instance, Baiwesilicone will have an IP61 rating for its products if the rubber is dipped in water.

14. What Is The Quality Of Chinese Rubber Seals?

Chinese rubber seals are of the highest-grade quality.

Baiwesilicone in particular is an international level manufacturer of rubber seals and silicone rubber products.

The company has a mold making plant, a silicone rubber compression molding plant, and liquid silicone rubber injection molding plant. Each of the plants lives up to the standards of a BSCI audit and provides premium quality rubber seals.