Advance Equipment Rubber O Ring Factory

Baiwe is the leading rubber O ring manufacturer and provider in China. We can custom plenty of silicone rubber parts and components. We have an expert team that help us to produce a stable and flexible rubber O ring. We are the perfect manufacturer that you need for your business.

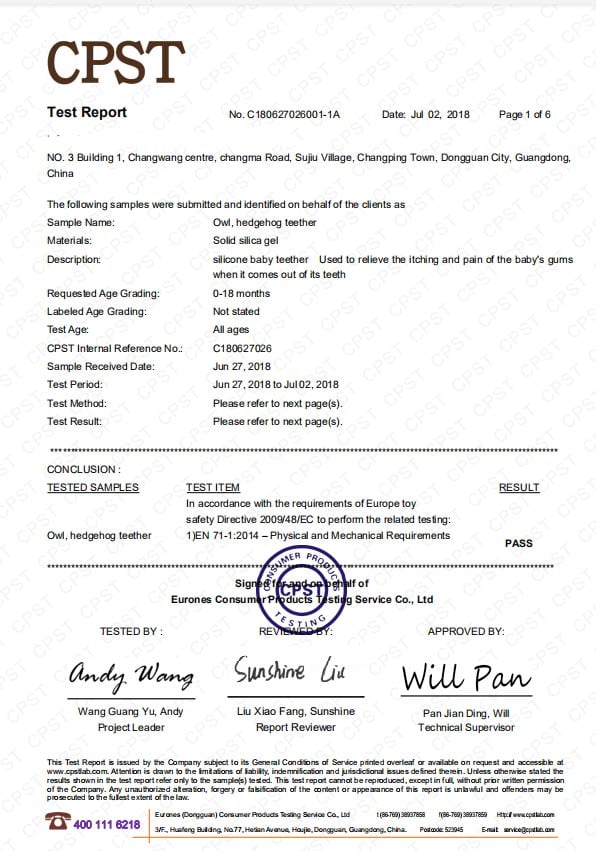

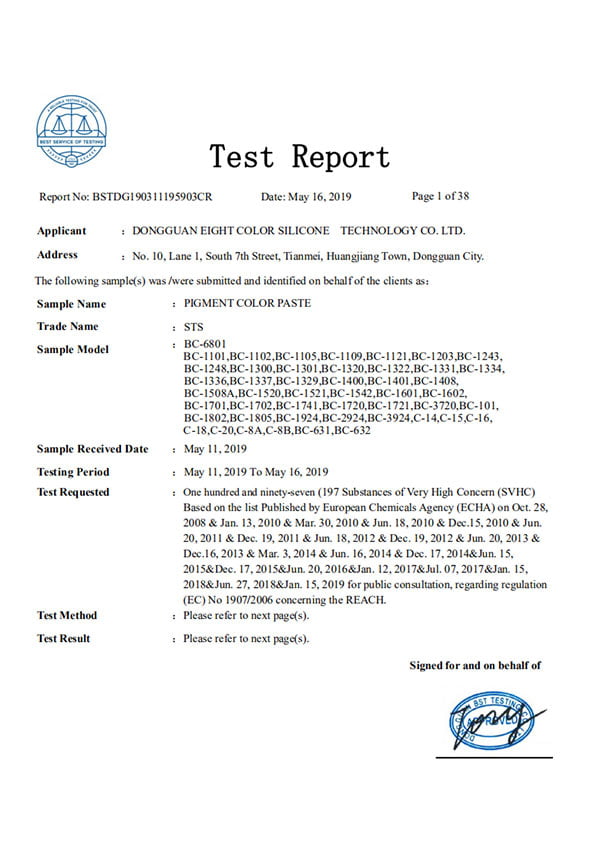

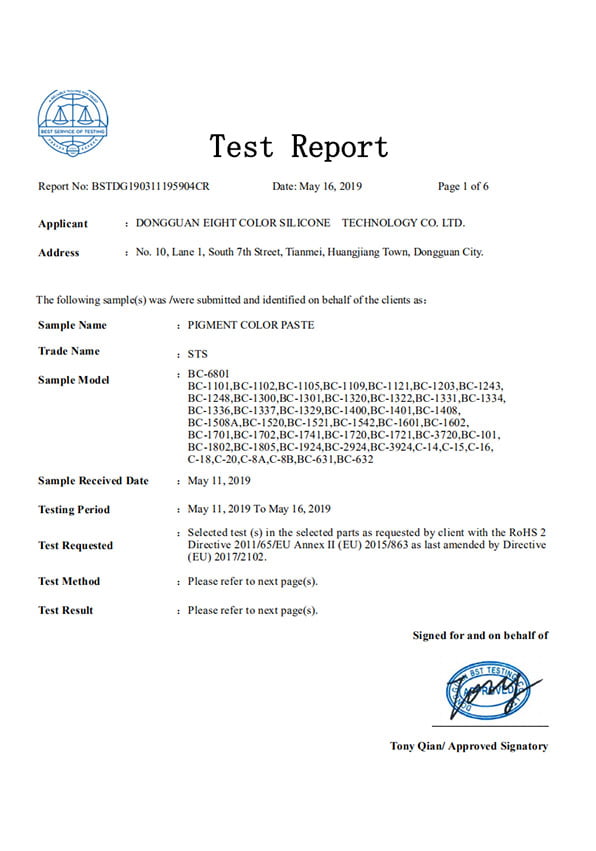

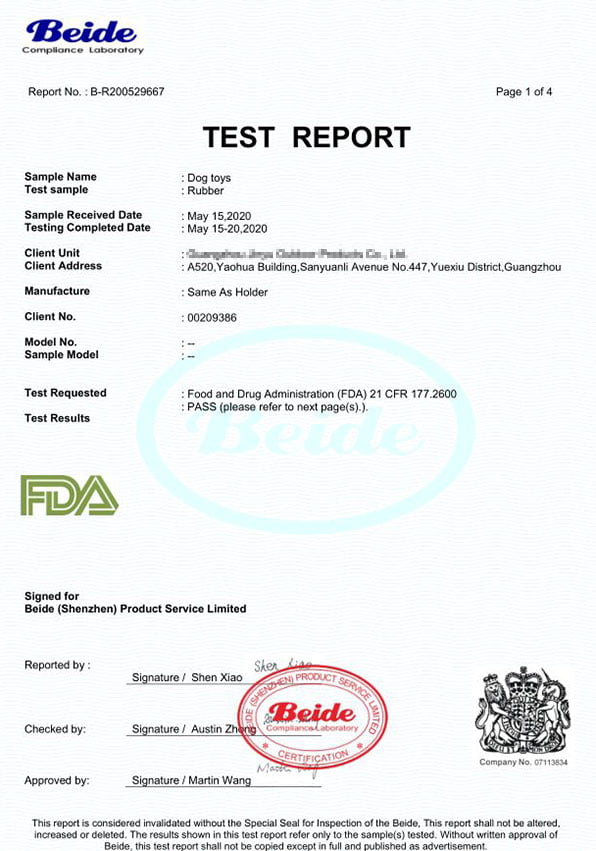

We got many certifications such as the BSCI, ISO9001, FDA, and LFGB. We can provide an efficient rubber O ring with the highest quality. Whether you need an extraordinary rubber O ring manufacturer, Baiwe is the best solution for you.

A rubber O seals ring is easy to clean and easy to replace. It composes of safe and durable rubber parts. Rubber O seals rings are perfect in a wide range of applications.

The rubber silicone O ring comes in various sizes. You can cope with multiple household needs since the rubber silicone O ring has great fitting sizes and features.

Nitrile rubber O ring features an oil-resistant, good sealing, more flexibility, and water abrasion. It forms by solid and high-quality nitrile rubber materials.

The rubber O ring gaskets seal has the best mechanical performance. Rubber o ring gasket seal is perfect for electrical fields and other applications.

This is a soft and flexible type of rubber O ring and is capable of using many times. It is available in a wide range of sizes, from 6mm to 30mm.

Natural elastic rubber O ring can effectively prevent and eliminates an air leak. This is available in color black in any size. It can also minimize finger fatigue.

1 mm rubber O ring features good airtightness and strong sealing. It is a smart rubber part that can prevent leaking for plumbing, hydraulic, machinery, and pneumatic repairs.

A matte rubber O ring without glitters can sustain heat temperature between a range of 86°F to 248°F. This is a unique rubber O ring that blocks any leak issues.

The colored rubber O ring uses environmentally friendly materials. It is available in various colors like violet, green, black, white, and more.

This is a multifunction rubber O ring with features pressure-resistant, oil-resistant, water-resistant. Ideal to use in different industrial applications.

Peroxide cured silicone rubber O ring has a soft structure but is not easy to deform. It is convenient and flexible to use for a wide range of purposes.

A hydraulic rubber O ring has quality assurance making it the best rubber O ring choice. Choosing the hydraulic rubber O ring brings extra benefits, and your cost will be worth it.

Baiwe: One-Stop Solution Provider For Your Rubber O Ring Project

If you find an excellent rubber O ring that brings extra benefits, Baiwe is the right place to count. We can provide a handy rubber O ring and any silicone rubber components that are suitable for various applications. Baiwe is well-known as a trusted and reliable rubber O ring manufacturer with rich experience.

Baiwe is a veteran rubber O ring manufacturer in China. We have an extensive in-stock of rubber O ring products that are ready to ship and deliver. For your wholesale and bulk orders for rubber bellow, rubber bumper, rubber gasket, rubber grommet, rubber washer, etc., we can fully support that.

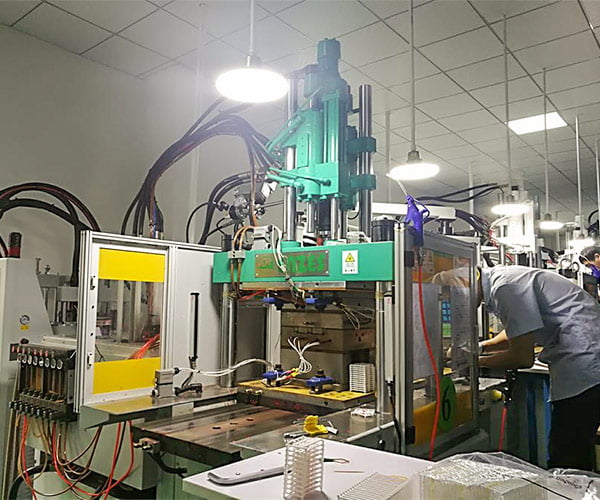

- Manufacturing

- Certifications

- Top Quality Control

Baiwe- Your Professional Rubber O Ring Manufacturer and Supplier in China

Baiwe is an ISO-certified rubber O ring manufacturer in the mainland of China. We commit ourselves to manufacture and supply an exceptional rubber O ring. Baiwe can provide an ultimate solution for those needing quality silicone rubber parts.

Baiwe rubber O ring is an accessible rubber part that perfect for a wide range of applications. It is applicable for plumbing, households, automotive, and machinery fields. Choosing a Baiwe rubber O ring will make your cost back guarantee.

Baiwe rubber O ring is flexible and durable, which meets the best sealing. They are available in various colors like violet, green, black, white, clear, and more. A rubber O ring has an excellent and superior trademark making them the best choice.

A rubber O ring features an oil-resistant, water-resistant, pressure-resistant, and so on. They have plenty of sizes range from 1 mm up to 30 mm. You can ensure that you can get a rubber O ring with suitable fitting sizes.

We have several types of rubber O ring such as the rubber O seals ring, rubber silicone O ring, nitrile rubber O ring, rubber O ring gaskets, and clear silicone rubber O ring. The natural elastic rubber O ring, 1mm rubber o ring, and colored rubber o ring are also available at Baiwe.

Baiwe is a master rubber O ring manufacturer that capable of providing an en exact and right one. We have more than 15 years of existing in this industry. Baiwe has enough experience, knowledge, and understanding in the silicone rubber parts industry.

Baiwe has complete confidence to offer rubber O ring products in different markets nationwide. Suppose you desire to have a versatile and elastic rubber O ring for your business count on baiwe. We will never hesitate to provide our services and quality products.

Please feel free to send us your inquiry!

Rubber O Rings – The Ultimate FAQ Guide

Do you want to start a business, but worry about gas leakage?

Are you not comfortable transporting gas cylinders with rings installed in order to ensure safety?

In this case, rubber O rings will come in handy.

There are some useful questions in the following guide about the properties, applications, and types of rubber O rings.

So let’s get started!

- What’s Are Rubber O Rings?

- What Are The Benefits And Features Of Rubber O Rings?

- What Is The Shelf Life Of Rubber O Rings?

- What Are The Applications Of Rubber O Rings?

- How Are Rubber O Rings Manufactured?

- What Are The Different Types Of Rubber O Rings Available?

- How Are Rubber O-Rings Sized?

- Do Rubber O-Rings Stretch?

- Can You Use Rubber Instead Of O Ring?

- Does Rubber Oil Swell O-Rings?

- How Much Should An O-Ring Be Compressed?

- How Do You Make O-Rings Seal Better?

- How And Why Do You Lubricate Rubber O-Rings?

- Do O Rings Stretch Over Time?

- What Are FFKM O Rings?

- What Are The Limitations Of Rubber O Rings?

- How To Choose The Best Rubber O Rings Manufacturer In China?

1. What Are Rubber O Rings?

Rubber O rings are the particular type of seal rings made up of the highest quality silicone. They are also called the mechanical gaskets for the gas cylinders having a specified cross-section.

Rubber o-rings are also considered packing joints that act as a stable loop for sealing the different applications.

In addition to this, these unique silicone O rings are mainly designed to be installed in the grooves or between the compressed parts of two different parts.

In such a way, the rubber O rings will create a seal for the package at the interface. These rings are mainly used in the parts where there are relatively static or dynamic motions.

They are also made up of the highest vulcanized solid material, which makes them resistant to other fluids, gases, and unfavorable environmental conditions.

![]()

2. What Are The Benefits And Features Of Rubber O Rings?

The benefits and features of rubber O rings are explained as under:

- They are available with a fixed cross-sectional area

- They are made up of a particular type of sturdy material, including silicone

- They are installed in grooves or in between the two different surfaces in contact

- They play the leading role to seal a prominent range of temperature and pressure

- The sealing property of the rubber O rings comes from the availability of the fixed cross-sectional area

- They don’t provide any kind of smearing and re-tightening

- There’s no need of installation tools for integrating the devices

- They don’t allow the gas or liquid to escape from the computer

3. What Is The Shelf Life Of Rubber O Rings?

The shelf life of the rubber O rings is estimated at up to 3 years. However, the shelf life of these silicone rings depends on the type and the material used in their construction.

Shelf life is defined as the time for which a manufactured product remains stable. In addition to this, the shelf life of the rubber O rings starts from the manufacturing day of these silicone rings.

Furthermore, the shelf life of the rubber o rings differs from manufacturer to manufacturer. Different manufacturers offer different rubber O rings with a varied shelf life.

The manufacturer uses the expertise and the judgment of the storage for determining the shelf life of the rubber O rings.

![]()

4. What Are The Applications Of Rubber O Rings?

The different applications of the rubber O rings are listed as under:

- They are used in the containers for preventing the leakage

- They are used when the temperature is the main working factor

- Silicone rubber O rings are used primarily to resist the high temperature

- They are also used in the abrasion industry

- The tearing, steam, water, and petroleum industries are some focus points for the application of the rubber O rings.

- They have both static and dynamic applications.

- Rubber O rings are also used in agriculture and the automotive industry.

- Silicone rubber O rings are famous for their applications in the dynamic and static fields.

BAIWE can be your go-to choice since they have wide applications of rubber O rings

5. How Are Rubber O Rings Manufactured?

The following steps manufacture the rubber O rings:

- The first step in the manufacturing of the rubber o rings is the special molding press

- In the molding step, the raw materials are directed to the particular molds for getting a desired contour of the materials

- Besides this, the compression molding includes the preparation of the rubber O rings by using an extrusion system

- The use of high temperatures and pressures yields the raw materials to make a circular shape called the O-ring

- After this, the manufactured O-rings are then separated from the burr

- The manufacturing of the rubber O rings is then followed by the inspection for making sure everything about the quality and accuracy of the product

BAIWE is also one of those Chinese manufacturers that use top-notch manufacturing methods for generating the premium quality of rubber O rings.

![]()

6. What Are The Different Types Of Rubber O Rings Available?

The different types of rubber O rings are listed as under:

- PTFE O rings

- Nitrile O rings

- Neoprene O rings

- EPDM Rubber O rings

- Fluorocarbon (Viton) O rings

- Silicone O rings

- Polyurethane O rings

- Ethylene propylene rubber O rings

- Viton O rings

All these O rings are distinguished by the different types of materials used in their construction. Other than this, they perform the same function to seal the containers.

7. How Are Rubber O-Rings Sized?

The sizing of the rubber O rings depends on the three dimensions regarding the application you’re using.

You need to keep in mind these three dimensions while sizing the rubber O rings include the Outside Diameter (OD), the Inside Diameter (ID), and the most important one is the Cross Section.

The manufacturers are suggested to compare these dimensions very carefully when sizing all types of rubber O-rings.

The sizing of the rubber O-rings is considered a pretty simple procedure. The engineers are advised to record all measurements of the O-rings in millimeters.

8. What Is The Difference Between Black O Rings And Green O Rings?

The primary difference between the black O-rings and green O-rings is the nature of the materials used in their construction.

Black O-rings are mainly made up of the highest quality of the Neoprene or Nitrile material. In some cases, there is a combination of two different materials.

Whereas the green-colored O-rings are made up of the premium quality of Hydrogenated Nitrile, also known as saturated nitrile or HNBR.

Besides the nature of the materials, the green and black O-rings also differ in their applications.

Black O-rings are mainly used for auto-air conditioning applications, whereas green O-rings deal with the high-temperature values and the intense working stress. They are integrated into the solar systems.

9. How Do I Know What Size O-Ring To Buy?

You can know the correct size of the O-ring according to the desired application.

The majority of the potential manufacturers in China offer various sizes of rubber O-rings for different applications.

Thus, you must have an idea about the insights of the application before choosing the right size of the rubber O-ring.

10. How Do You Select an O-Ring Cross-Section?

You can select the proper O-ring cross-section by following the given steps:

- You can take an estimate of the O-ring cross-section by taking an idea from the available sizes.

- The next step for selecting the right O-ring cross-section is to check the maximum clearance of your application.

- Check the radial seal of the application.

- Make sure that the calculated clearance must be acceptable for the application pressures.

- Now when you’re done with calculating the clearance of the application, the next step is to calculate the O-ring groove dimensions.

- Check the gland depth of the application for the Or-rings

- Don’t forget to check the groove width. It must be larger than the thickness of the backup ring

- Also, determine the maximum perfect gland fill of the application

- Also, calculate the seal squeeze for deciding the right O-ring cross-section

11. Is Rubber O-Rings Fuel/Oil Resistant?

Yes, almost all types of rubber O-rings are considered fuel/oil resistant. This is why they are used in a wide variety of applications.

The different rubber O-rings are resistant to many substances, including water, fuel, oil, gasoline, petroleum oils, crude oil, and even propane.

The resistance property of the rubber O-ring has made them perfect for a wide variety of applications under different temperature conditions.

![]()

12. Do The Color Of O-Rings Make A Difference?

Yes, the color of an O-ring makes a significant difference in its properties and applications.

The color of the O-rings comes from the material or combination of materials used in their construction.

That is why manufacturers like BAIWE provide an extended list of the O-rings depending on their length.

Furthermore, the O-ring color affects the material’s compression and the property of the O-ring, including the resistance and physical properties.

Do O-Rings Come In Different Thicknesses?

Yes, O-rings are available in different thicknesses depending on the type of applications they offer.

The thickness of the o-rings differs both in inches and millimeters. The cross-sectional area of the O-rings is directly related to their thickness.

The estimated Diameter of the rubber O-rings ranges from 0.040 to 0.275 inches. However, the insider diameter of these O-rings ranges from 0.029 to 25.940 inches.

13. Is Silicone O-Rings Better Than Rubber?

Yes, silicone O-rings are better than rubber O-rings because they can easily be applied to high temperatures without getting any substantial change in their properties.

In addition to this, the silicone O-rings aren’t affected by the other elements, thereby causing no problem in their applications.

Silicone O-rings give a better range of benefits, including high thermal stability and substantial chemical resistance.

14. Do Rubber O-Rings Stretch?

Yes, rubber O-rings can easily be stretched but only to a particular extent. By stretching them, you can fit them snugly in the groove of the applications.

However, the stretch in the rubber O-ring is estimated up to 1% to 5%, with mostly 2% in the majority of the applications.

The stress significantly accelerates the cross-section reduction and aging of the rubber O-rings due to stretch.

15. Can You Use Rubber Instead Of an O Ring?

Yes, you can use rubber instead of O-ring since it’s regarded as the best substitute for all types of seals.

The majority of the manufacturers prefer using the rubber seal gaskets instead of the O-rings in various applications.

Furthermore, there are also many other options that you can use as the best alternative for O-rings. These substitutes include flange seals, static radial seals, composite sealing plates, axial face seals, and press-in place seals.

![]()

16. Does Rubber Oil Swell O-Rings?

Yes, rubber oil causes the O-rings to swell. However, the amount of swelling in O-rings depends directly on the chemistry of the oil and the exposure temperature.

The greater the exposure temperature, the greater the swelling in the O-rings.

Besides this, the majority of the manufacturers in China have now developed elastomers that reduce the swelling extent in the O-rings when exposed to rubbers.

Other than this, the swelling of the O-ring will continue to rise unless the insider elastomer maintains a stable equilibrium.

17. How Much Should An O-Ring Be Compressed?

An O-ring can be compressed up to 1% to 5% depending on the pressure and the temperature applied.

The compression of an O-ring also depends on its inside Diameter. For compressing the O-ring to a substantial value, it’s suggested to have a smaller piston groove diameter.

Compression larger than 5% in the O-rings is not recommended.

![]()

18. How Do You Make O-Rings Seal Better?

You can make the O-ring seals better by following the given tips:

- Make sure to consider the environmental conditions, including the temperature, when selecting the elastomers

- Check the appropriate dimensions of the O-rings seal for their better working

- The size of the O-rings seal must be equal to the application’s size

- Calculate the volume/void ratio before installing the O-rings seals on the applications

- Test the working of O-ring seals before using them

- Consider the application type for making the O-ring seal perform in a better way

19. How And Why Do You Lubricate Rubber O-Rings?

You can use the highest quality of silicone oil or molybdenum disulfide for lubricating the rubber O-rings. The lubrication of the rubber O-rings must be carried out before or after molding while treating the seal.

In addition to this, the lubrication of the rubber O-rings must be carried out on the surface of the molded rubber products.

You should lubricate the rubber O-rings because:

- It helps to increase the lifespan of the O-rings

- It protects the O-rings from pinching and cutting

- The cracking is also reduced because of lubrication in the rubber O-rings

- The installation is also carried out quickly with the lubrication of O-rings

20. Do O Rings Stretch Over Time?

Yes, the majority of the O-rings become stretched or loose over time and need to be replaced or removed for the better working of the applications.

The properties of the rubber O-rings make them change their size over time, thereby leading to increased expansion.

Moreover, the O-rings also stretch over time when they are exposed to high temperatures.

21. What Are FFKM O Rings?

The FFKM O-rings are precisely described as Perflouroelastomer seals. Unlike the rubber O-rings, they are considered the best innovation.

The primary reason behind the increasing demand of the FFKM O-rings is their sufficient resistance towards chemicals and high temperatures.

Moreover, they are also resistant to the degradation caused by aggressive fluids and gases.

![]()

22. What Are The Limitations Of Rubber O Rings?

The limitations for the rubber O-rings are listed as under:

- They come with a rotary speed ranging up to 1500 feet per minute

- Rubber O-rings are available with the improper mating

- The mating of rubber O-rings is not compatible with the hardware design

- They are not compatible with temperature, pressure, and fluid chemicals

23. How To Choose The Best Rubber O Rings Manufacturer In China?

You can choose the best Rubber O-rings manufacturer in China by following the given tips:

- Make sure to go through the options available on the internet

- Choose the manufacturer that stands rightly on all your demands

- Try to contact the chosen manufacturer through their email or phone

- Explore the different options of O-rings present on the manufacturer’s site

- Check the manufacturing experience of the supplier or manufacturer

- Don’t forget to check the availability of R&D service for quality production of rubber O-rings

- Make sure about the presence of quality and safety certificates at the manufacturer’s site

BAIWE is the best manufacturer of rubber O-rings in China because they stand on all the production criteria.