Advanced Rubber Molding Technology and Proficient Production Process For Your Rubber Parts

The application range of rubber parts is very wide Nowadays. As a professional rubber parts manufacturer and supplier, we can customize industrial rubber parts, consumer rubber parts, chemical rubber parts, and medical rubber parts for you.

Baiwe has more than 15 years of experience in the production of various types of rubber parts and has become one of the best rubber parts manufacturers and suppliers in China. We have a strong production capacity for your rubber parts project.

Send me your specific request now and we will reply to you with the best price immediately.

Automotive Molded Rubber Parts

We can custom made molded rubber parts for you

Different shape and colors molded rubber parts made by rubber injection molding

Molded Rubber O rings

Custom molded rubber seal

We can custom made different silicone rubber keypad

Baiwe:We can Custom Made All Types of Rubber Parts To Skyrocket Your Business

If you are now looking for a rubber parts manufacturer, you are in the right place, we are the one of leading rubber parts manufacturers in China. If you cooperate with us, you can get the following professional services,

- One-stop solution for Rubber Parts: We have professional CNC mold opening equipment and abundant skilled workers, and can provide you with precise rubber molding services. We have qualified workers to produce big volume rubber parts for you, and a professional after-sales team here for you.

- High-precision rubber molding service: we can control very small abrasive differences. Our technicians have an average industry experience of more than 7 years. It can provide a wear tolerance of ±0.01mm for your silicone rubber parts project.

- Perfect parting line and smallest flashes: It is well known that improper parting line and flashes will affect the appearance and use of the rubber parts product. We can solve this problem for you and, we have the confidence to be your top list of a rubber parts manufacturer.

Call us or email us right now, our support team will reply to you in 4 hours.

- Manufacturing

- Certifications

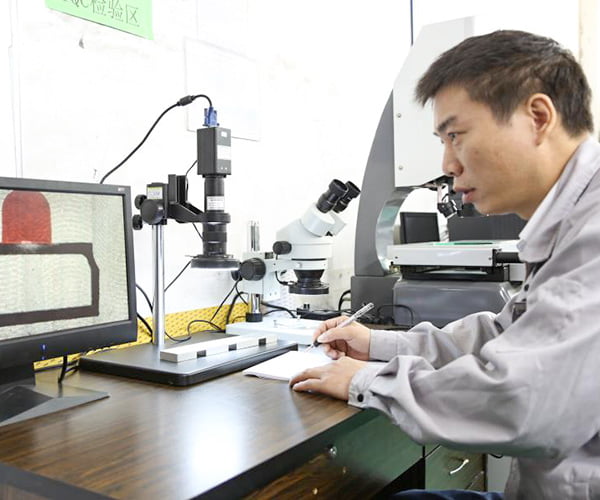

- Top Quality Control

![]()

We Can Offer You a Full Range of Rubber Parts For You

As the professional rubber parts manufacturer and supplier in China, we can custom made all kinds of, rubber bellow, rubber bumper, rubber gasket, rubber o rings, rubber grommet, rubber washer, etc.

Should you need support right now? Call Us!

Custom Rubber Parts– Ultimate FAQs Guide

Are you a businessman who is looking for some custom rubber parts in bulk?

If that is the case, then this ultimate FAQ guide will help you in that regard.

This guide covers all the edges of information for customer rubber parts that you need to know before starting your business.

- What’s Are Custom Rubber Parts?

- What Are The Advantages Of Custom Rubber Parts?

- How Long Custom Rubber Parts Last?

- What Is General Process Used For Custom Rubber Parts Manufacturing?

- What Are The Uses Of Custom Rubber Parts In Different Industries?

- What Are Different Custom Products That Can Be Manufactured From Rubber?

- What Are The Major Terms To Discuss Before Ordering Custom Rubber Products From China?

- What Are Different Types Of Rubbers To Choose From For Custom Rubber Parts?

- What Are Different Injection Molding Methods Used In Custom Rubber Parts Manufacturing?

- What Are The Tools Used In Injection Molding For Custom Rubber Part Manufacturing?

- What Are Custom Rubber Parts Used In Automotive Industry?

- What Are Custom Rubber Parts Used For Noise Reduction?

- What Are Custom Rubber Parts Used For Vibration?

- How Much Does It Cost To Manufacture Custom Rubber Parts?

- Who Manufactures Custom Rubber Parts?

- Are Custom Rubber Parts Easy To Manufacture?

- Are Silicon Products Better Than Rubber?

- Does Custom Rubber Parts Harden With Age?

- What Are The Quality Standards Of Custom Rubber Parts From China?

- Is Custom Rubber Parts Made In China Safe?

- How To Choose The Right Custom Rubber Parts From China?

1. What Are Custom Rubber Parts?

The custom rubbers parts are products made from injection or compression molding of rubber.

![]()

These parts are useful in machinery to avoid friction in some cases, whereas some are used to provide strength to a working mechanism.

The custom rubber parts are mostly used in automobile and extreme engineering industries where the need for rubber parts is helpful in reducing the friction of moving parts.

The widely used procedures for developing rubber parts are transfer molding process, injection molding process, and compression molding.

Compressing molding is a method of producing prototype or low-volume rubber parts, whereas injection molding helps to create high-quality and effective rubber parts.

Each solution provides high precision, low waste, and flash-less features.

2. What Are The Advantages Of Custom Rubber Parts?

There are three major advantages of using custom rubber parts.

They are Durable

The biggest benefit of the custom rubber parts is that it is durable.

They have good strength due to rubber material along with the composition of other materials that provide enough strength and stretch to improve the quality of the product.

They can last in high tension and pressurized situations where machines have to work under loads for hours.

They are not affected by heat or temperature unless or until the temperature is too high.

Enhance Performance

The custom rubber parts are designed specifically for their purpose of use which enhances the performance of a mechanism.

A part that completely fits its place in a working system can increase efficiency and reduce workload problems.

Custom-made rubbers are always better because they are precisely created to fit perfectly.

As a business, you want to provide the greatest product available so that your supplied part doesn’t dissatisfy the customer.

Versatility

Rubber has a high strength-to-weight ratio while being less stiff than many other materials.

On the other hand, it can withstand more tension and wear than other materials.

Custom Rubber parts are versatile and can also be used as an insulating material that is non-conductive.

3. How Long Custom Rubber Parts Last?

The normal lifespan or shelf life of a custom rubber part is around 3-5 years.

If it is kept at room temperature, then it may last for more years which depends on the storage conditions.

Custom rubber part’s quality and its shelf life can vary as it may even past the expiration date of its shelf life in some cases if kept in the right conditions.

The projected shelf life can be shortened due to poor storage conditions. Rubber items should be kept dry and cold and kept away from sources of heat and moisture.

Temperatures should be kept below 25°C, although temperatures below 15°C are desirable.

Rubber items can lose their physical qualities and become unusable as a result of storage.

Rubber products should be carefully reviewed for possible usage as originally intended if the shelf life has expired.

4. What Is General Process Used For Custom Rubber Parts Manufacturing?

The general process that is used for custom rubber parts manufacturing is the injection molding process.

It is a process used to build the rubber parts that are formed by using pure rubber with the bonding of other components.

![]()

The process consists of the following steps.

- A nozzle, base with an ejector system, and a runner plate, along with the cavity plate make up a basic injection mold that is used to eject the parts after molding.

- A strip of the rubber material is naturally supplied into the molding machine in the process.

- The raw rubber is pushed via an injection nozzle by a screw-type plunger once it has been heated in the barrel.

- The rubber enters the nozzle plate, travels through the runner plate, through gates, and finally into the mold cavities.

- After the cavities are filled, the mold that is heated is then sealed under high pressure for the amount of time necessary to cure the rubber.

- When the rubber is bonded to other components, they are put into the heated mold cavities by hand or with a loading apparatus.

- The mold cavity is closed after that, and the injection molding process can commence.

- The mold is opened, and components are removed after the process is complete.

- In setup for the next molding cycle, the treated rubber in the runner is removed.

- The rubber that is left in the injection nozzle is purged, and it is formed in custom shape, after which the mold cavities are cleaned.

5. What Are The Uses Of Custom Rubber Parts In Different Industries?

There are lots of uses of custom rubber parts in various industries based upon their design and structure.

Some major uses industries and their uses are.

Automotive Industry:

![]()

In the automotive industry, custom rubber parts play a major role in engine mounts, vibration reduction, door and window seals, extruded tubing, etc.

They are also produced as bushings, sound damping rubbers, and wiring.

Construction Industry:

Custom rubber parts are useful for noise control, engine mounts, bushings, making belts for machinery, buttons, and knobs in the construction industry.

Defense Industry:

There is a vast use of custom rubber parts as vibration reduction mounts in heavy machines.

They are also made for tracks and rifles or other such equipment that help to reduce metal collision.

Mass Transit Industry:

The use of custom rubber parts in the mass transit industry fits well for making grommets, bumpers, tubing, window seals or door seals, and other such things.

Medical Industry:

These custom rubber parts also play a major role in the medical industry, where there is the use of tubing, extrusions, syringes, catheters, and gaskets.

Agriculture Industry:

There are huge mechanical systems in agricultural industries due to which custom rubber parts are produced for vibration reduction and noise control.

Environmental seals are frequently made of rubber or rubber-like materials.

Rubber is an excellent choice for sealing because of its natural ability to conform and compress.

It can be used for off-road vehicle battery compartment seals to digital equipment wire organizers.

6. What Are Different Custom Products That Can Be Manufactured From Rubber?

There is a variety of custom products that can be easily manufactured using rubber material.

Car Parts

The rubber material can be molded into various car parts on custom choice, depending on the size and shape required.

They come in all sizes and shapes to fit every type of necessity in the manufacturing of cars.

Custom Rubber Spare Parts

The formation of custom spare parts using rubber help to fulfill the need of any specific part required for any vehicle or machine.

Custom Rubber Grommets Parts

Rubber has wear resistance and temperature resistance, due to which it is well suitable for making custom rubber grommets.

Seals Parts

Sealing is important in every aspect when there is a machine working or when there is a construction for which custom rubber parts always fit the need.

Custom Molded Rubber Parts

Based on the demand or desire of a customer or business, the custom molded rubber parts can be formed into a multiple shape.

Industrial Custom Rubber Grommets Parts

Industries have their specific use of machines in which they require custom rubber grommet parts to reduce friction or noise.

Universal Custom Rubber Parts

The universal custom rubber parts are desirable for universal applications like in electronics, the automobile industry, or household applications.

7. What Are The Major Terms To Discuss Before Ordering Custom Rubber Products From China?

In case you want to place an order for custom rubber parts from a Chinese manufacturer, you will need the necessary documents.

![]()

- You will need to discuss customs declaration, insurance policy, invoice, bill of lading, shipping list, along with the sales contract.

- You will also have to discuss the specialized document for the import quota certificate to allow your shipping for general products.

- An import license, safety license, inspection certification, and quality certification are also necessary to be discussed before placing orders.

8. What Are Different Types Of Rubbers To Choose From For Custom Rubber Parts?

There are different types of rubbers that can be used for manufacturing a product for custom rubber parts. These types include.

- Natural Rubber

- Silicone rubber

- EPDM Rubber

- SBR (Styrene-butadiene)

- Synthetic Rubber

- Neoprene rubber

- Nitrile rubber

- Butyl rubber

9. What Are Different Injection Molding Methods Used In Custom Rubber Parts Manufacturing?

There are three basic injection molding processes that are basically used for making custom rubber parts.

Organic Rubber Injection

Material preparation is critical for the process of organic rubber injection molding.

The rubber is measured into the screw after it has been blended and peeled.

Once the barrel is filled with the correct amount of material, it is injected into the mold’s cavities, where it cures.

This procedure has the power of eliminating the requirement for operators to place pre-forms and preheating the rubber.

This can also lengthen the cycle time and finally form the shape of rubber.

Liquid Injection Molding

In Liquid injection molding, there is a mixer, where a two-part liquid silicone compound is combined.

After curing, the mixture is placed in an injection unit.

The flow of the prepared rubber compound is directed by runners and gates installed into the mold cavity.

Before the next step of the molding process, all rubber part materials cure inside the mold and are then evacuated.

This method has the advantage of limiting contamination due to closed systems and shortening cycle times.

Thermoplastic Rubber Injection

In this process, Elastomers are processed similarly to plastic and perform similarly to rubber.

Thermo Plastic injection is a similar method to injection molding.

The time and effort of mixing and vulcanizing are eliminated by not using actual rubber material.

TPEs, or thermoplastic elastomers, are used in injection molds and can be colored and recycled.

The fact that these are only useful in high-temperature settings is a disadvantage.

These three options are the most popular and useful in the application of standards.

10. What Are The Tools Used In Injection Molding For Custom Rubber Part Manufacturing?

Cavity plates, Bolts, Ejector plate feet, risers, ejector locating plate, bolster sleeves, guide bushes, ejector plate retainer, and moving half support plates are used in injection molding.

The components that are used in injection molding for rubber are natural rubber, silicone, neoprene fluoro silicone, and nitrile, along with others.

11. What Are Custom Rubber Parts Used In Automotive Industry?

The most commonly used custom rubber parts used in the automotive industry are tires, hoses, gaskets and covers, bushings, seals, and covers.

The tires are one of the most visible pieces of a car composed of rubber.

Anyone who has ever opened a car’s hood has undoubtedly noticed a tangle of tubes flowing through the engine.

Rubber is used in a wide array of applications in the automotive industry.

This includes fluid transfer systems, body sealing systems, transmission systems, and automotive anti-vibration systems.

They are also used in the parts for sealants, adhesives & coatings, O-Rings, molded parts, etc.

Other uses of custom rubber parts in the automotive industry are for body parts, spare parts, and so on.

Noise and vibration dampening, muffler hangers, bumper stops under seats can also be considered.

12. What Are Custom Rubber Parts Used For Noise Reduction?

Rubber bushings are the custom rubber parts to absorb shocks and reduce noise and vibrations between components.

![]()

Rubber, polyurethane, and other materials are used to make bushings that reduce noise.

They’re installed on automotive suspension and steering joints to absorb road shocks, limit joint movement, and decrease noise and vibration.

It is a form of vibration isolator that connects two stiff pieces with a flexible contact.

Shock absorbers’ rubber functions as a buffer, absorbing and damping the energy generated by the interaction of these two sections.

13. What Are Custom Rubber Parts Used For Vibration?

The most commonly used custom rubber parts for controlling vibration are anti-vibration pads.

These pads are made for pumps, motors, laboratory equipment, consumer appliances, and HVAC systems.

They help to reduce vibration in the systems.

When we consider the automotive industry, the rubber bushings are made to control the vibrations of movement in the vehicle.

14. How Much Does It Cost To Manufacture Custom Rubber Parts?

The manufacturing of custom rubber parts includes a great deal of procedure, due to which they are expensive.

It can cost about $500 to a high range of $3500 based upon the type of custom rubber part and its manufacturing process.

A Chinese manufacturer for custom rubber parts can always provide a cheap production at minimal rates.

15. Who Manufactures Custom Rubber Parts?

There are lots of manufacturers for custom rubber parts around the world, but Chinese manufacturers are specialized in this process.

Baiwesilicone is the best example as a leading custom rubber parts manufacturer that provides top-quality parts in less time.

The parts produced by this manufacturer are pretty cheap but very tough and effective to use.

16. Are Custom Rubber Parts Easy To Manufacture?

The production of custom rubber parts requires a whole process of molding, which is not easy to handle to manufacture.

It requires expertise and specialization to properly manufacture the best custom rubber parts for the market.

The Chinese manufacturers put their efforts and time into completing the manufacturing process for custom rubber parts through long processes.

17. Are Silicon Products Better Than Rubber?

Silicone products are not better than rubber because both of them have their differences, and each of them has the benefit over the other one in different terms.

The main distinction between rubber and silicone is that most rubber forms have carbon-carbon bonds in their backbones.

The atomic structure of silicone distinguishes it from rubbers. Silicones also have more unique qualities than regular rubbers.

Rubbers are either naturally occurring or may be synthesized, whereas silicon is only found in synthetic form.

Silicone differs in this case because it has silicone and oxygen in its backbone.

Elastomers include rubber and silicone. They are polymeric materials that show viscoelastic behavior, or elasticity as we know it.

The natural rubber can withstand temperatures as low as -50 degrees Celsius.

Silicone, on the other hand, can withstand significantly higher temperatures than natural rubber.

Natural rubber begins to degrade at 80 degrees Fahrenheit and melts at 120 degrees Fahrenheit.

Silicone can be designed to work at temperatures as high as 230°C.

Silicone also outperforms natural rubber in terms of flame resistance.

Silicone is unquestionably the better choice for high-temperature applications.

Hydrocarbon fuels and lubricants are not well tolerated by silicone or natural rubber.

Silicone, on the other hand, has a higher chemical resistance than natural rubber, making it a superior choice for chemical sealing.

In chemical applications, however, the material chosen will be determined by the specific chemicals with which the material will come into contact.

Both materials are put in piping and tank lining applications.

The natural rubber has far stronger tensile, tear, and abrasion resistance than silicone.

It’s employed in applications with a lot of wear, such as tire treads and conveyor belts.

Silicone has a limited abrasion resistance; thus, natural rubber is a preferable choice in conditions where a part will be subjected to abrasion or strict wear.

Silicone is commonly used in outdoor applications such as door and window seals because of its high weathering and UV resistance.

Natural rubber, on the other hand, weathers quickly and is unsuitable for outdoor use.

Silicone is the best choice if your application is exposed to the elements.

18. Does Custom Rubber Parts Harden With Age?

Custom rubber parts harden with age when the softening chemicals known as plasticizers leak out.

![]()

Plasticizers keep rubber pliable, so they can be used more effectively.

The process of hardening can take years, but it can be stopped before the rubber becomes too brittle to handle.

Rubber is a versatile and easy-to-work-with material.

Rubber, like most materials, will degrade over time as a result of common environmental elements such as heat, light, and ozone.

19. What Are The Quality Standards Of Custom Rubber Parts From China?

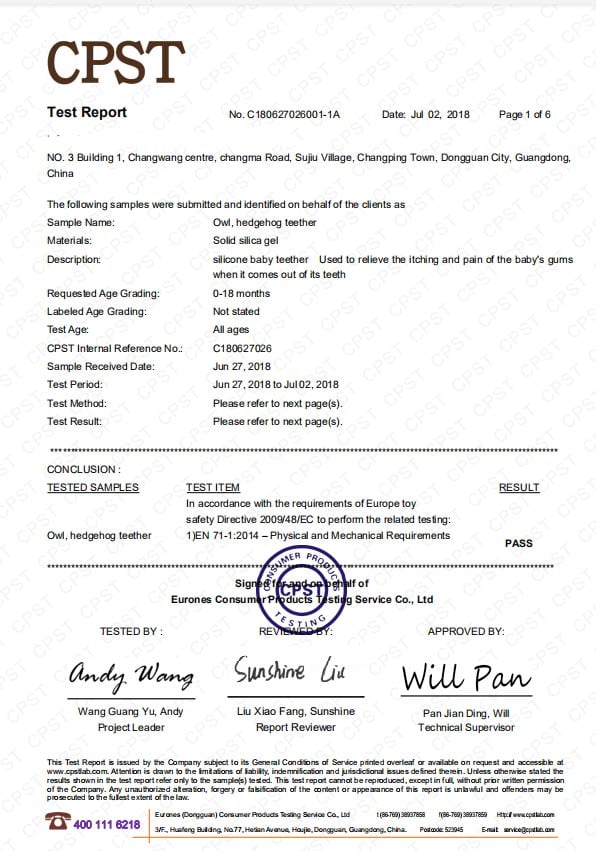

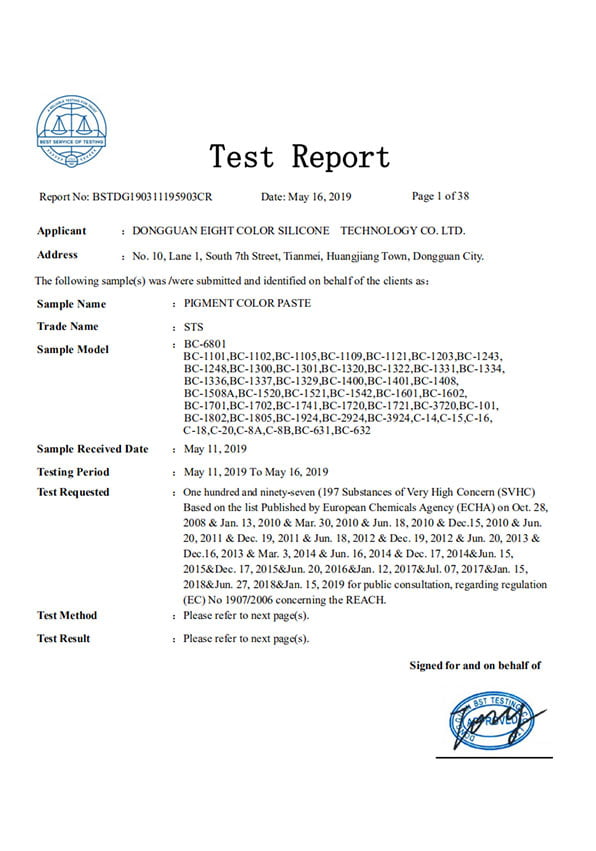

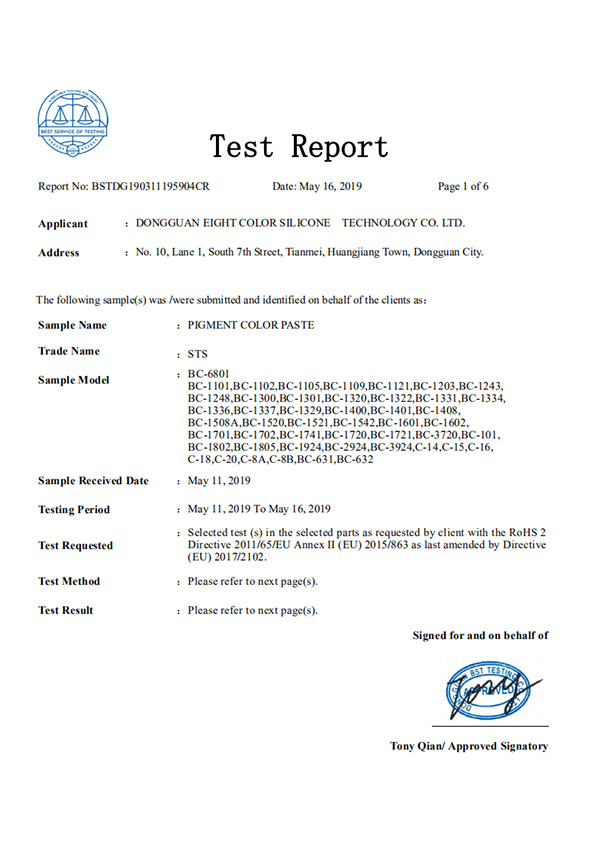

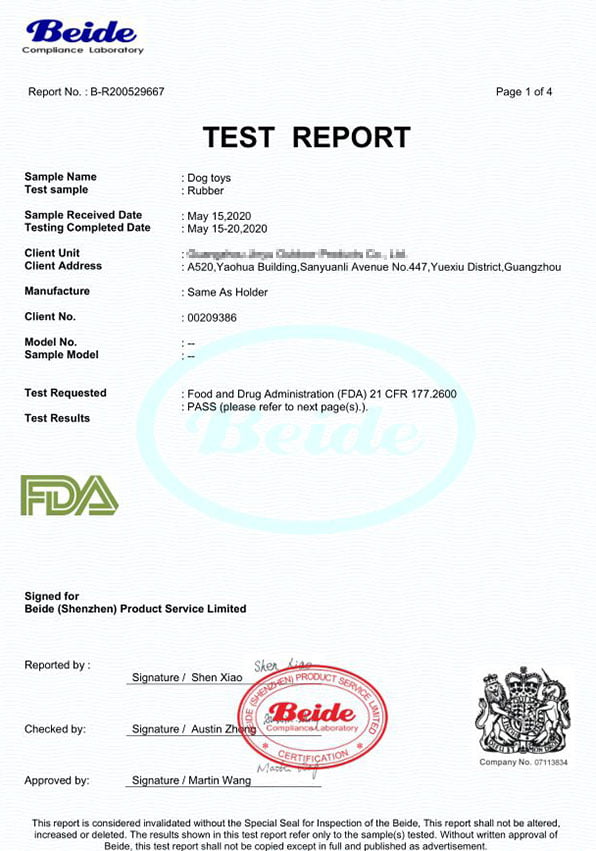

The quality standards that the manufacturers from China use to produce custom rubber parts are EN71, Reach-197, Rosh, and FDA.

![]()

Baiwesilicone is a qualified and certified manufacturer from China that provides the top-quality standard products for your business.

20. Are Custom Rubber Parts Made In China Safe?

If you order your custom rubber parts from a trusted manufacturer in China, it’s always a safe choice to consider.

There are a number of trusted suppliers who manufacture and supply top-quality custom rubber parts all over the world from China.

You just need to confirm and make sure that the manufacturer that you are dealing with must have a good customer dealing history by reading reviews and talking to other people.

You can also select try Baiwesilicone, They are one of the best manufacturers in china.

21. How To Choose The Right Custom Rubber Parts Supplier From China?

To choose the right custom rubber parts supplier from China, you need to consider the following things.

Plan Your Business:

The first and most thoughtful step is to plan your business in which you will highlight what your business is working on and what type of rubber parts you need.

Meet the Supplier:

After planning, you need to find the best manufacturer for supplying your desired custom rubber parts with a trusted contract.

Check Its Quality Control:

You need to make sure that the manufacturer that you are dealing with will provide the top-notch quality that you are looking for.

Sign The Agreement:

At last, finalize your documentation and agreement in the contract by stating every condition with legal approvals.

Order Samples:

Before you order in bulk from the manufacturer, you can choose to order samples first to see what you will get for your money.

In case the quality is satisfactory for your market business products, then move on with the agreement and choose that manufacturer as your supplier.