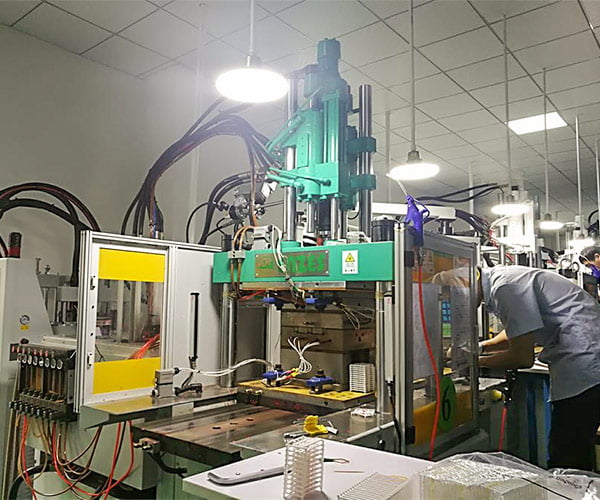

Rubber Injection Molding Factory

Baiwe is your primary source of high-standard rubber injection molding equipment. We accept any manufacturing standard of rubber product, even if it is OEM and ODM. all of our rubber injection molding is an ISO, RoHS, REACH-197, and EN-71 certification passer. We take up all the production processing procedures of rubber injection molding in our factory. Such as rubber compression molding, rubber transfer molding and Rubber Extrusion.

Baiwe consistently implements regular check-ups of rubber injection molding. We can provide you with every single sample and manual of rubber injection molding as we give you the privilege to check its quality—a 1-year warranty for each rubber injection order. Baiwe is always your best choice for your rubber injection molding.

Rubber injection molding silicone is perfect for shaping an object out of fixed silicone and rubber materials—High-efficiency rubber injection molding equipment for rubber moulded components.

It has a unique element that enables it to form an object’s double-colored and frequent appearance. It is a high-resistance rubber injection equipment that works even in heavy-duty applications.

Each rubber foam injection molding has the most extensive part size that measures 1500*1500mm. Every model surpasses the ISO-9001 product certification.

Baiwe is your perfect option for rubber ear-pod case injection molding equipment. The component in each molding equipment manufactures from fixed aluminum and steel materials.

Easy to operate rubber slipper strap injection molding that aids you to mold a bulk of slipper strap. Any style and formation of slipper strap can be processed using this equipment.

Rubber round ball injection molding has a unique mechanical power that is useful for generating all sorts of round balls with matching designs, styles, and colors—a perfect partner for the growth of your business.

This rubber earbuds tip injection molding set its high capacity to operate with high power voltage that gives a factor to produce massive earbuds tip. It comes in different models and sizes.

Rubber nipple injection molding gives you a 100% satisfying and stable performance. It is not easy to be rusted nor damaged; hence it will operate conditionally even in heavy-duty applications.

A vast selection of washer gasket rubber injection molding is accessible here at Baiwe. It gives you the most precise and satisfying result of your gasket molding materials.

Custom rubber rain boot injection molding manufacturers from 100% sturdy aluminum and other raw materials. It will help you to develop every version of rain boots, whether OEM or ODM.

Baiwe provides a type of molding equipment that is useful in producing a potable water system material. Rubber hose injection molding in anti-corrosion equipment can sustain even in high-pressure surroundings while operating.

Each category of rubber watch strap injection molding comes in different sizes and measures. It is a practical watch strap molding since it can produce multiple watch straps in a single operation.

Rubber Injection Moulding Process | Custom Rubber Part

Rubber injection molding refers to the production method of heating the rubber material through an injection machine, then injecting it from the barrel into a closed model under pressure, and then pressing and vulcanizing it into a product. After plastic is plasticized in the heating barrel of the injection molding machine, it is injected into the cavity of the closed mold by the plunger or the reciprocating screw to form the plastic processing method of the custom rubber products. This method can process products with complex shapes, precise dimensions, or with inserts, and has high production efficiency.

It’s pretty challenging for you to seek an expert rubber injection molding manufacturer and supplier. Try to avail yourself here at Baiwe cause we have a skillful molding team who will help you seek the best rubber injection molding. We enhance to provide a series of molded rubber products.

Baiwe presents the most upgraded version of rubber injection molding every week. Quickly place us your rubber injection molding parts orders or LSR molding parts as we can deliver them to your locations as soon as possible!

- Manufacturing

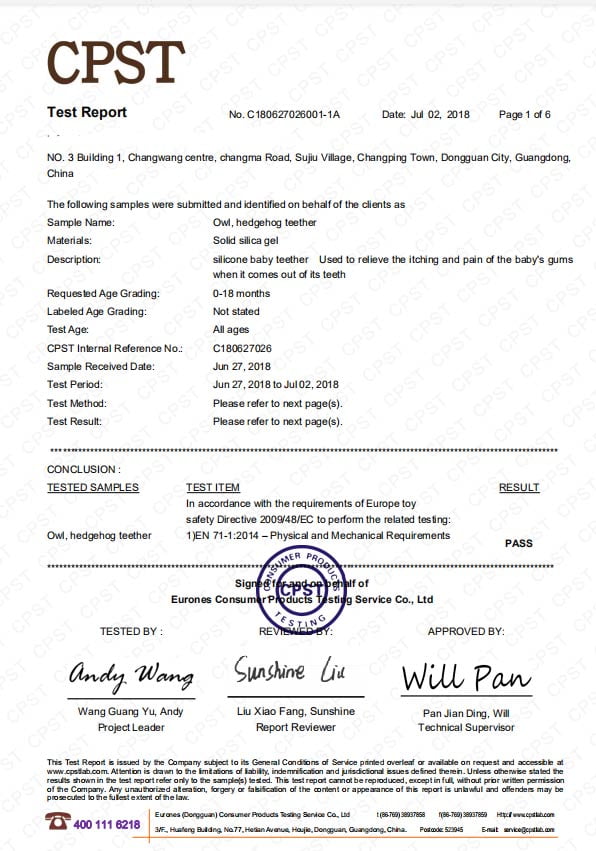

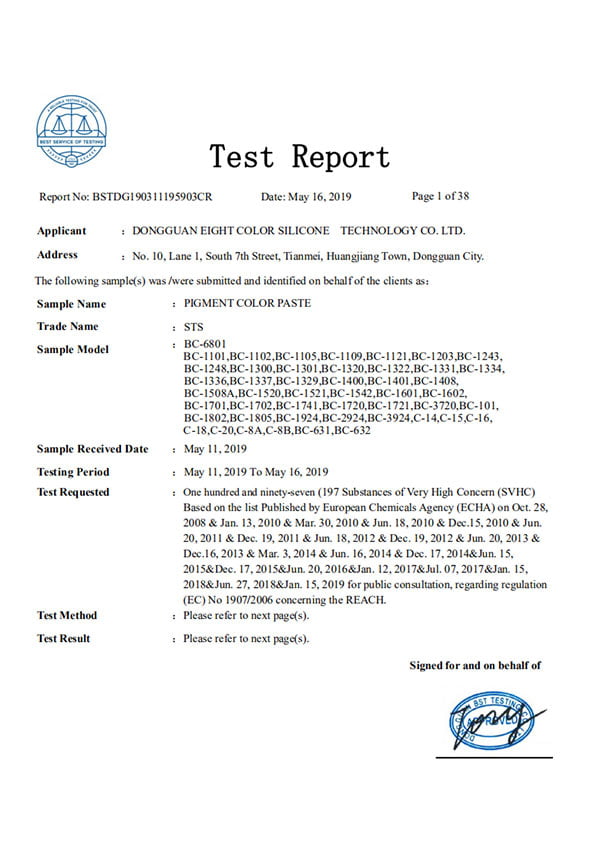

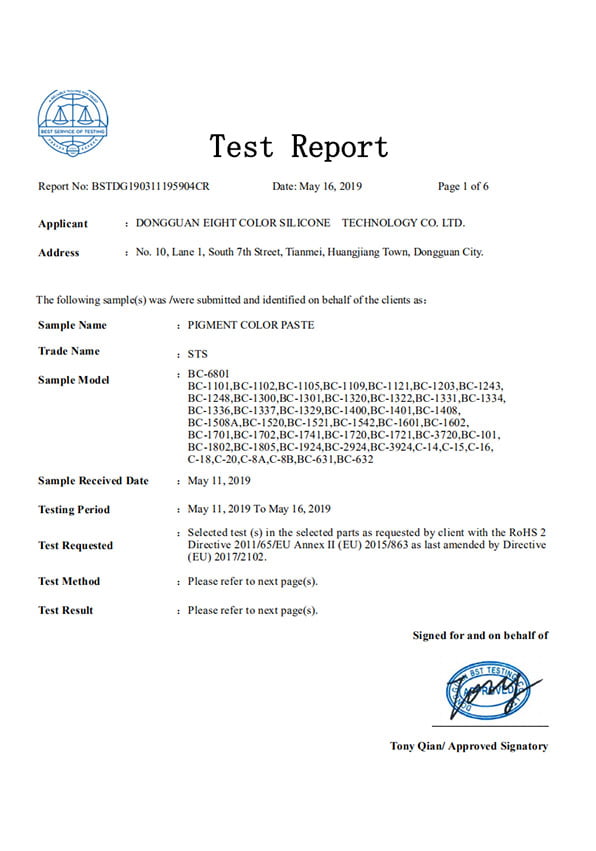

- Certifications

- Top Quality Control

Baiwe: Your Outstanding Rubber Injection Molding Manufacturer and Supplier in China

Baiwe has taken part in the field of molding production business for almost 15 years. We have sufficient knowledge, understanding, strength, and talent in manufacturing and supplying rubber injection molding that makes us trusted in this industry.

Furthermore, managing a massive rubber injection molding production business is not that easy. But as a prominent foundation, we keep manufacturing a bulk of rubber injection molding as we strive harder to comply with all your requirements. Baiwe continues creating a successful name and notorious brand in rubber injection molding.

In addition, we widely offer the lowest purchasing rate of rubber injection molding and yet are functional for all molding applications. Perfect for rubber molded rubber bellows, rubber bumpers, rubber grommets, etc. It hugely helps you, especially for your mold-making business, where it makes it possible for you to produce plenty of molding products.

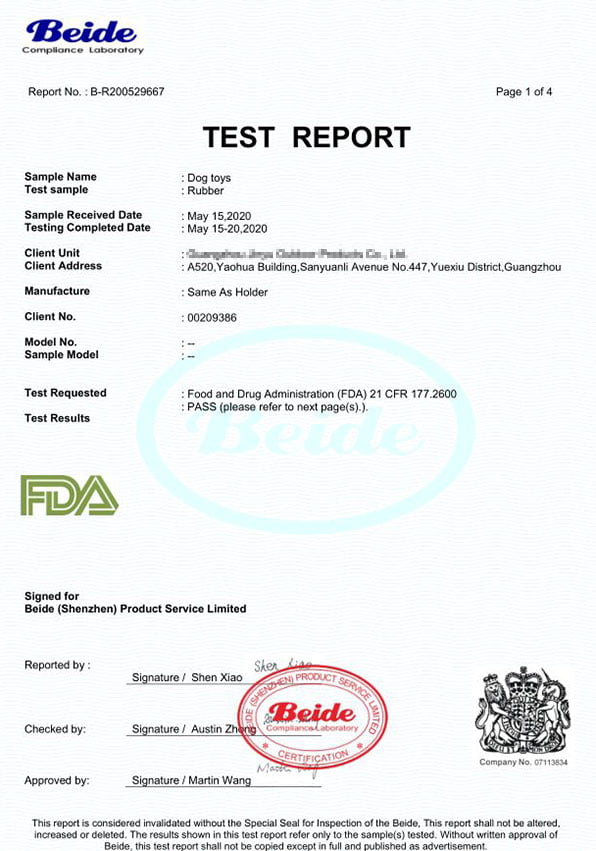

Our rubber injection moldings already submitted all the product management certifications, specifically the Phthalate Free, ISO, EN-71, RoHS, and REACH-197. A solid and adequate proof that our product is eligible to use. We have these skills and experience engineers who take part in this production line. Every stage we have taken, from layout, product analysis, materials, procedure, and delivery, is 100% guided by management inspectors.

Within 15 years, plenty of shareholders and customers believe in what our rubber injection can do to reach a wealthier molding business. As a prominent manufacturer and supplier, we only provide a world-class solution of rubber injection molding equipment. Baiwe engages in distributing rubber injection molding to all worldwide famous markets.

Baiwe is your best choice for manufacturing rubber labels, rubber O Rings, rubber seals, and rubber washers.

For the latest update about rubber injection molding, check our official website!

Rubber Injection Molding Temperature

Temperature is a necessary condition to ensure smooth injection and rapid vulcanization of the compound. The choice of barrel temperature is related to the characteristics of the extruder and the vulcanization characteristics of the rubber compound. Generally, the temperature of the plunger barrel is controlled at 70~80°C, and the temperature of the reciprocating barrel is 80~100°C, which should generally not exceed 120°C. The injection temperature should be as close to the mold temperature as possible under the premise of scorch safety. The mold temperature is generally selected to be 3~5°C lower than the scorch temperature of the rubber compound, and the maximum vulcanization temperature of natural rubber can be 180~200°C.