Advanced Equipment Rubber Grommet Molding Factory

Baiwe has complete selections of a rubber grommets for your various applications like automotive purposes, furniture industry, fitness, and equipment applications. We prioritize quality rubber grommet and related products but offer an affordable cost to lessen your budget.

Auto industry applications of rubber grommet are more durable and effective to protect wirings etc. Guaranteed acceptable prices for your business.

Choose a black rubber grommet, which one of the popular colors in this application. It has a variety of sizes and shapes that will meet your project needs.

We supply bulk orders and low MOQ of a rubber grommet with your ideal colors and shapes. Affordable prices according to your choices.

Send your ideal rubber grommet from sizes, colors, shapes, applications, and more. We will offer one-stop solutions for your business.

A dustproof rubber grommet for your final applications will be more useful for your final applications. Tear-resistant that provides long-life service.

Easy to fabricate, easy to use, and an affordable rubber grommet that Baiwe offers for your final applications. Provide quality production at a cheaper price.

We are one of the leading rubber grommet manufacturers that produce to the fitness industry and custom according to your requests which offer friendly cost.

Looking for a reliable rubber grommet for the furniture industry and visit Baiwe is your great choice. We have plenty of shapes, sizes, and more selections.

Different machinery purposes with a quality rubber grommet. We can manufacture and custom your sizes and shapes at lower prices.

Silicone rubber grommet for the automotive industry, constructions, and more applications apply to the quality molding process.

We manufacture standards sizes of rubber grommets. Using rubber compression molding, we produce a quality rubber grommet appearance.

Baiwe rubber grommet is waterproof that keeps wires and cable secured. It has great thickness, colors, and appearance that you can choose.

Baiwe: One-Stop Solution Provider For Your Rubber Grommet Project

Baiwe is a professional rubber grommet manufacturer and supplier in China that will fulfill your demands quickly. We will custom your rubber grommet request.

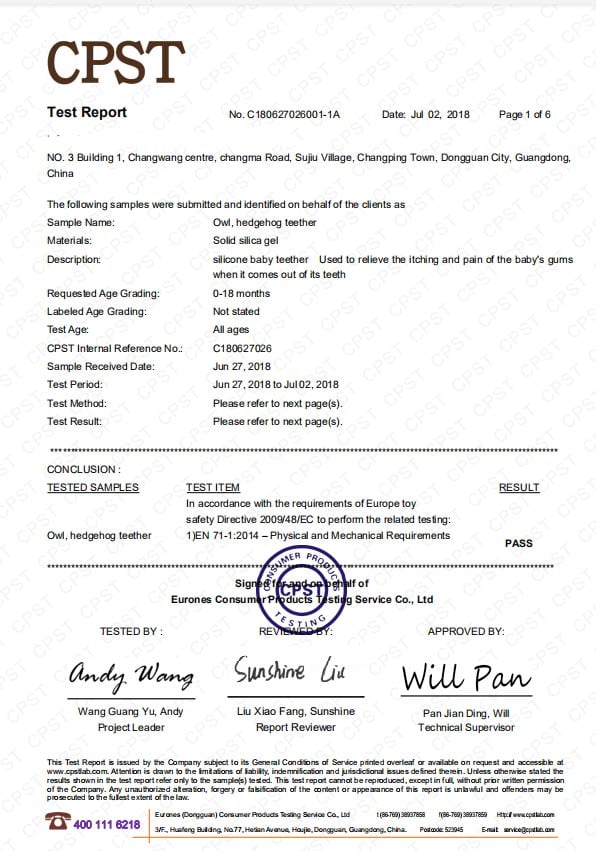

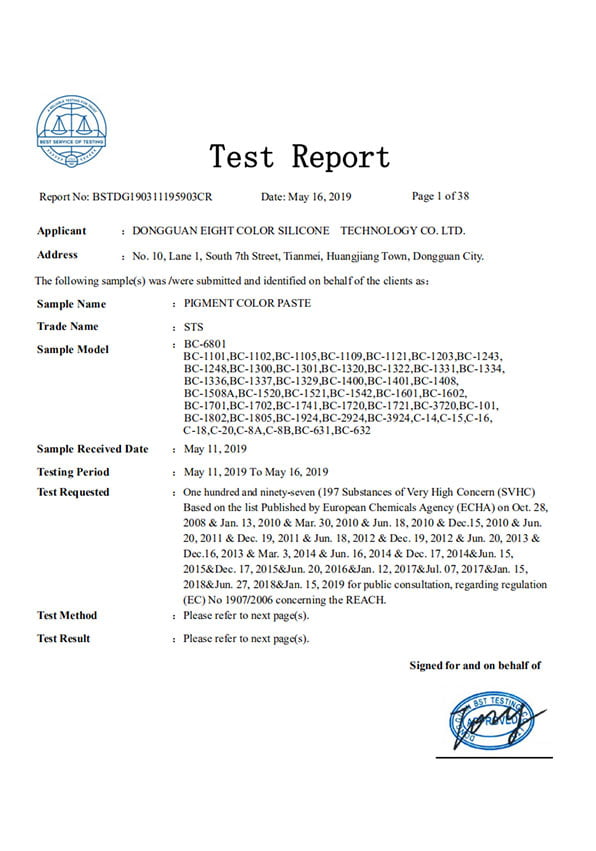

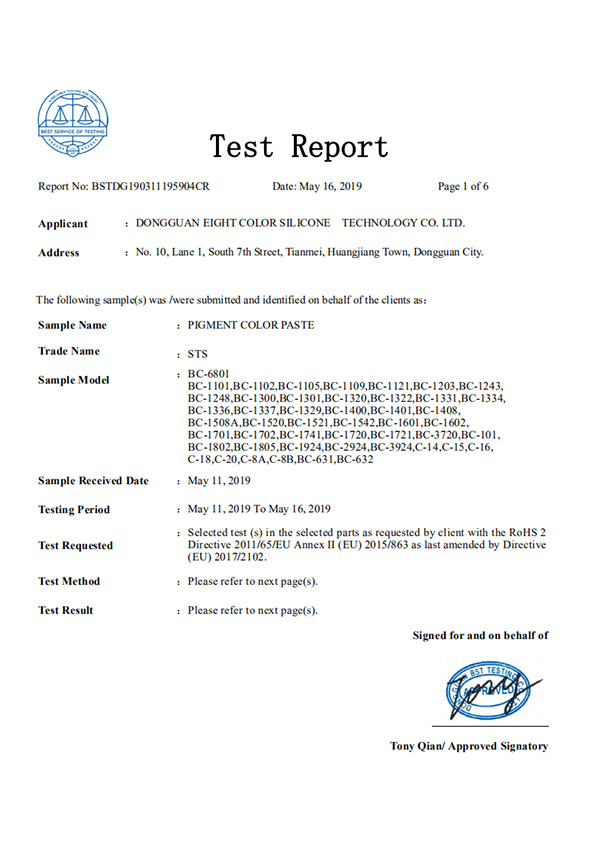

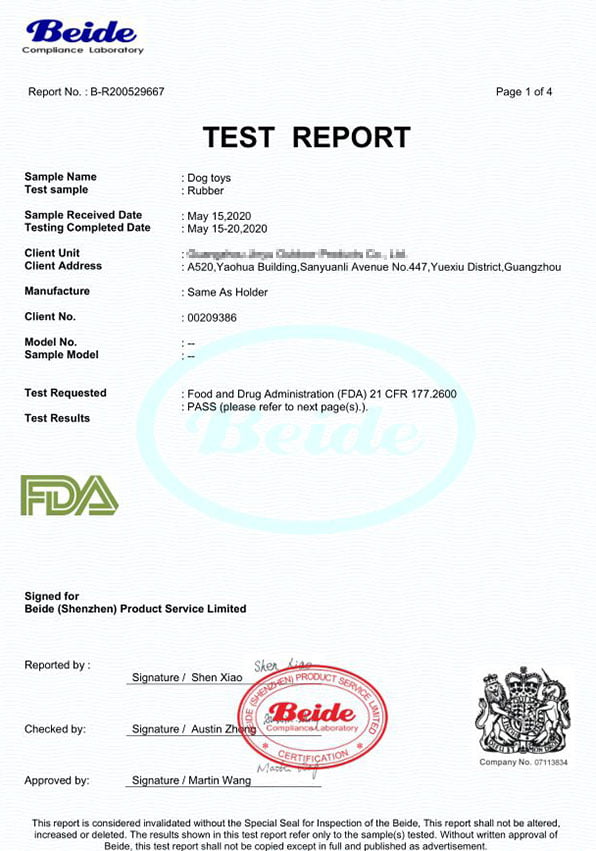

As your professional producer and partner, we will ensure great benefits for your handled business. Our rubber grommet is certified that you can trust to provide amazing performance to your project. Our rubber grommet is FDA and SGS approved that surely guarantees high-quality and long-life service.

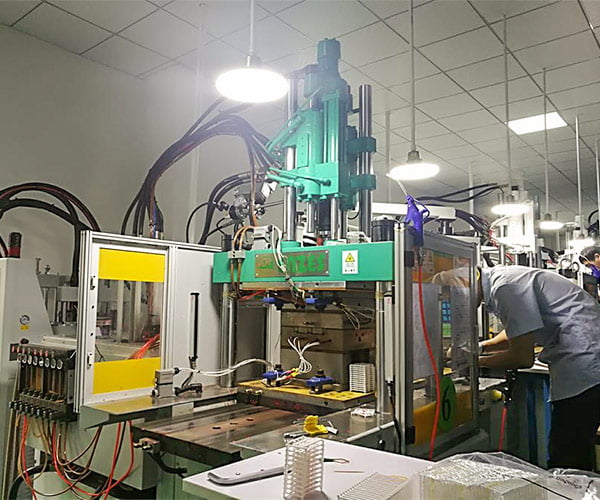

- Manufacturing

- Certifications

- Top Quality Control

Baiwe Rubber Grommet

Are you looking for a durable and effective rubber grommet in China? Well, this is the best place you visit.

Baiwe is a popular manufacturer of rubber grommets and related products and producers that can reach many countries and regions around the world. We supply excellent quality rubber grommets applicable for plenty of applications that can hide rough and sharp edges. It protects the wires and cables in holes from sharp surfaces.

Baiwe rubber grommets have various applications that give importance to all applications that serve plenty of purposes. It can protect the cable from passing through the holes. It is important to all constructions applications, automotive applications, and more.

You can choose a lot of selections and consider a lot of advantages. Rubber grommets are weather resistant that far from UV and ozone effects. Rubber grommets have perfect heat resistance and tear resistance that more durable for many purposes. It will not lose easily because of the perfect fit that can handle different temperatures.

Baiwe rubber grommets are easier to install and replace, which is a more economical and perfect solution. You can get different sizes, colors, shapes, and types of applications. You can choose the black color which commonly people in business choose because of dirt resistance ability. We have rectangular, round rubber grommets, oval, and different sizes like 16mm, 20mm, and more sizes selections.

Ensure to meet your business special requirements and ensure to get the best support with Baiwe. Whether you need them for personal purposes, retail business, wholesale business, supplying different stores, and even owned factories, we will assure you 100% support.

We have more than 15 years of experience providing excellent service and one-stop solutions. You can rely on us and free your time worrying about the whole process. You can directly connect with us.

Get in touch now!

Rubber Grommet– Ultimate FAQs Guide

Are you working in an industry that involve the use of Rubber Grommets?

If yes, then you might be looking for where to buy Rubber Grommets in bulk for you industrial use or looking for the best deal.

In any case this ultimate FAQs guide for Rubber Grommet that will help you sort out everything about Rubber Grommets.

- What Is Rubber Grommet?

- What Are The Uses Of Rubber Grommet?

- What Are The Benefits Of Rubber Grommet?

- How Long Will Rubber Grommet Last?

- How Are Rubber Grommets Made?

- What Are The Different Types Of Rubber Grommets?

- What Are The Physical Properties Of Natural Rubber Grommets?

- What Are The Material Options For Rubber Grommets?

- How Do You Size Rubber Grommets?

- How Do You Apply Rubber Grommets?

- Are Rubber Grommets Waterproof?

- How Do You Remove Rubber Grommets?

- How Do You Stretch Rubber Grommets?

- Can You Use Rubber Grommets On Fabric?

- Do Chinese Manufacturers Offer Custom Grommet Design Service?

- What Is The Quality Of Chinese Rubber Grommets?

What Is Rubber Grommet?

Rubber grommets are a piece of a part made out of Rubber that finds their use in covering any sharp edges of a machine or part.

They find their most of the use in electrical engineering, and they provide additional protection and safety from water and dust.

![]()

There are several functional benefits of using these grommets in machines as they help to avoid frictional damage.

They protect the wires, cables, or pipes from any cuts or pressure impacts that may influence a process.

They are fitted along with flared collars so that they can stay in place and keep safe for use.

Some grommets like edge strip rubber help to provide a decent appearance to a machine in order to use for any process.

Rubber grommets are usually found in black, but they are also available in grey as well as in transparent material too.

They are also called Eyelets, Edgings, bushings, or insulating bushings.

These rubber grommets have good resistance to Moisture, Heat, Low temperatures, Weather, Ozone, UV light, etc.

They also have resistance to Hydrochloric, saltpeter, phosphoric, and sulfuric acid along with Strain and Alkali environments.

The rubber property doesn’t let them crack or come loose easily.

They don’t require screwing or any such way to be inserted upon anything, and they also don’t need locking nuts.

They are meant to be pushed on a surface to fit properly with their stretchable properties with external pressure.

What Are The Uses Of Rubber Grommet?

Rubber is a tough substance and offers a few advantages in contrast with other grommet materials.

Rubber grommets are flexible items that are generally utilized in purposes to fix holes and avoid impacts in components.

Their chief uses include:

- They help to covert sharp edges of openings in metal plates to shield links and lines from cuts and scraping harm.

- Rubber grommets give strain help, grasping wiring set up and limiting the harm.

- They avoid interruption that may happen if the rope or link was unintentionally pulled.

- They play a good role in reducing motor vibration in vehicles and different machines.

- They are used in Electronics to avoid conductivity to unusual places and protect the board from damage.

- They are used in the construction of projects to avoid impact and friction between components.

- They are vastly used in Automotive designing, Aeroplane designing, and aeronautics and also in Telecommunication industries.

- They are used in developing Medical hardware for safety purposes.

What Are The Benefits Of Rubber Grommet?

There are many advantages of utilizing rubber grommets over different sorts of grommets.

![]()

- This sort of Grommet is additionally tougher and tear-safe.

- It doesn’t evaporate, break and come loose at any point without force.

- Rubber grommets are more climate safe.

- They are not effected much from Ozone and UV Rays.

- They have high warmth opposition.

- Rubber grommets are more impervious to hydrochloric, sulfuric, phosphoric, and Saltpeter corrosives.

- It can deal with higher temperature unlike other types of grommets.

- Rubber grommets are quicker to install and they can be put on one side with a force.

- It is the best Grommet to utilize when space is confined since it doesn’t distend and gobble up a ton of room.

- It is better in design since you don’t need to physically screw it to fit into a place.

- Rubber grommets are more efficient and down-to-earth products.

In development, grommets are generally used to cover sharp edges of any holes in metal substances.

This is done to secure one more component as it has gone through this hole.

This sort of Grommet completely and securely holds the wire and helps you to pull a wire in case you want to.

They are also significant and beneficial in-car applications.

They are utilized to protect and keep lines, wires, or the cables safe from scraping with rough surfaces.

They can successfully reduce the vibration effect and are utilized to seal some points in the engine as well as in the body.

As a general rule, these grommets are used to cover holes and to cover the wires as well from sharp corners.

How Long Will Rubber Grommet Last?

A rubber grommet’s average property is very good due to its material used in the construction.

The average life of a rubber grommet to stay in its original position is about 9 months.

These rubber grommets can last for years if they are left untouched or disturbed at any point.

How Are Rubber Grommets Made?

Rubber grommets are normally produced out of rubber that can expel.

This can allow the manufacturers to shape them in any form they like.

Rubber expulsion is the interaction by which crude Rubber is compressed through hardware with heat to form a shape.

![]()

When the Rubber becomes liquid, it is constrained through a pass-on, which is an apparatus intended to shape crude materials into usable items.

At the point when the Rubber arises on the opposite side of the apparatus, it is permitted to cool and solidify once.

So, all things considered, it is cut and turns into a completed grommet.

Extrusion isn’t generally an appropriate grommet manufacturing process, but it can allow the creation of extremely straightforward shapes.

Infusion and pressure-forming cycles can create more muddled shapes.

The two cycles start the same way as expulsion; the Rubber is warmed to a liquid state.

Maybe than utilizing a pass-on, however, shaping cycles include the infusion of liquid Rubber into a pit.

Once constrained into a hole, liquid Rubber adjusts to the forms of the pit.

Pressure forming gives a new shpae to the Rubber, which guarantees that the Rubber will have good contact with the surface.

After the trim is finished, the Rubber is launched out from the shape, and it is permitted to cool and solidify.

The component is then cleaned of defects if required and then it is shipped or sent for extra handling.

What Are The Different Types Of Rubber Grommets?

Rubber grommets can be categorized into different types, and they are all listed below.

Insulation Grommets

Insulation grommets are those rubber grommets that help to protect the components used in industrial areas.

They are helpful in avoiding vibration isolation, and they provide abrasion protection as well as noise control too.

There are thousands of grommet styles in insulation rubber grommets with a lot of sizes and shapes.

Mil-Spec Grommet

Mil-Spec Grommet is formed in two compositions, and they have different formulas used for manufacturing.

The composition A requires Nitrile composition and such grommets find their use as resistant to any oil, UV rays or Ozone.

Composition B requires Silicone for its manufacturing, and they are widely used to resist low or high temperatures with UV rays and Ozone.

Rubber Blanking Plugs

This type of rubber grommet is helpful in sealing holes, and it can hold pressure in components from below and above.

They are mostly used for tubing and high-pressure UK devices for their properties.

Open Rubber Grommets

This type of rubber grommets have a central role in their structure, and they are one of the most common designed grommets.

![]()

They play an important role in covering and protect pipes and cables in any use of metal plating situations.

Closed Rubber Grommets

In this type of rubber grommets, there is a tight seal for the holes to avoid any kind of dust entering the component.

The air-tight seals of the grommet help to prevent dust which is why they are mostly used in electronic components.

Rubber Grommet Strips

These are distinct types of rubber grommets that have a unique design.

In this type, the strips sit along the edge of the plate so that it can smooth out and doesn’t cause any damage to the surrounding.

They are easier to cut and design, and there is a huge variety of these rubber grommet strips.

Tapered Rubber Grommets

Such type of rubber grommets is helpful in providing a blank hole for the seals in plates or metal panels.

They have a tapered design which is why they are very useful in thick panels.

Stepped Rubber Grommets

This type of Grommet has a tapered coned shape that comes at different intervals that are marked on it.

Through this, the users know from where they can cut the sizes of this rubber grommet.

It is used in making ideal multiple cable sizes according to the need or use in industries that produce cables and wires.

White Rubber Grommets

This type of rubber grommet is made from silicone in distinctive variety, which has good resistance to temperatures.

It has high and low temperatures resistances varying from -55°C and 180°C.

The special version of white rubber grommets can have good silicone-resistant temperature properties that can be around 800°C.

Custom Rubber Grommets

The custom rubber grommets, also called as special shape grommets, that are made on customer’s specifications.

This can involve the addition of rubber sizes, materials, and designs.

Easy Tight Rubber Grommets

This type of rubber grommet is utilized to ensure the edges of openings and the joints are secure.

This rubber grommet is made of adaptable Rubber material and points, keeping links set up safely.

This is helpful for rack installation, while neoprene/Rubber expulsions are reasonable for screens, windows, and vehicle security doors.

Multiple Port Rubber Grommets

This type of rubber grommets help to protect the corners of the holes on the cables or wires.

They have various ports which help to protect the product from contact damage or any external pressure.

The rubber material is used with adaptable properties in the construction of these grommets helping points keeping links set up safely.

These are good for rack introduces, while neoprene/Rubber expulsions are appropriate for screens.

U-Shape Rubber Grommets

This type of rubber grommets is used on boards to protect or shield the cables, ports, and wires from any edges of slots.

They are installed on the slots at the corners of a board so that any external contact or impact doesn’t harm the board.

The links and cable contacts are safe and free with this type of rubber grommets.

Rubber Grommets Style A

This type of rubber grommet is made with a collar on one side, and the opposite side is a conelike structure.

The other side of the Grommet can be changed to a conelike structure from barrel shape because of its flexibility.

They find their use in places where they are to be embedded into slots where there is no need of having two collars on a grommet.

They are used in places where wires, cables, links, or lines pass through any substance like glass.

They are also used in materials made of metal sheets, plastic, and other such substances to give good resistance to the component.

Rubber Grommets – Plug Style B

The Plug Style B rubber grommets are made with PVC or TPE, and they are used to provide more toughness to the component.

They can be used for both inner and outer applications due to their versatile properties.

They are excellent rubber structure that can be helpful in tough and pressure conditions machines.

What Are The Physical Properties Of Natural Rubber Grommets?

Natural rubber grommets have very good physical properties.

The temperature range that natural rubber grommet can bear is -70 to 80 ℃ or -96 to 170℉.

It has excellent tensile strength properties and elongation at the break.

![]()

The natural rubber grommet has very good abrasion resistance and rebounds resilience, along with a strong tear strength.

You can expect it to be a very strong and useful material that can be used in a lot of physical applications.

It can be turned into an oval, square, oblong, round, and rectangular shape for the use of multiple kinds.

Baiwesilicone ensures that customers get the best rubber grommet in all sizes and shapes.

You can now get your desired packages in bulk from the best manufacturer in China.

The rubber grommets that you will choose from this manufacturer is useful in various industrial applications.

This may include construction, defense, transportation, healthcare, and aerospace, as well as automobiles too.

What Are The Material Options For Rubber Grommets?

Rubber grommets are made from different materials by different manufacturer.

Some manufacturers use rubber, plastic, and metal.

While some are even made by using Nylon and Polyvinyl Chloride by using special grades of SBR, Silicone, Neoprene, and EPDM.

Other grommet materials that are used for rubber grommets are.

Natural Rubber

This material plays an important role as it provides resistance to tears and strain along with tensile strength.

It is also very good for strong electrical insulation.

Nitrile Rubber

This type of material makes the product highly oil-resistant, which makes it excellent to use in situations where a component has exposure to oil.

Having electrical conductivity properties being semiconductor that works between the insulator and a metal.

Fluorocarbon Rubber

This type of rubber material is stable and has effective properties to withstand strong acid, high temperature, and alkali environments.

Neoprene

It is the material that can resist flame heat and ozone corrosion, along with weather condition.

This is why it’s ideal for making rubber grommets that can be used outdoors and in areas of fire risk.

Silicone

It is an odorless material that also provides bright colors to the component.

It is a safe material that doesn’t affect human skin when it gets into contact with any person.

It is the best material to make rubber grommets that can be used in kitchen devices or any medical equipment and food processing machines.

How Do You Size Rubber Grommets?

Rubber grommets can be in different forms and shapes.

The thickness of a panel plays a major role in sizing the rubber grommet.

Once the ideal size is obtained, the company manufactures the rubber grommet for that size.

Different measurements can be utilized to quantify grommets.

For rubber grommets, the most essential are:

- The greatest cable breadth – for example, the biggest link that will go through the hole

- The board hole breadth – the size of the hole for embedding the Grommet

- The greatest board thickness – the profundity of the metal plate into which the Grommet can be embedded related to its length

The accompanying grommet graph records probably the most common sizes of rubber grommets.

| Max Cable Diameter | Panel Center Diameter | Max Thickness of Panel |

| 3mm | 6mm | 2mm |

| 4mm | 6.4mm | 2.5mm |

| 6mm | 9mm | 4mm |

| 10mm | 12mm | 2mm |

| 25.5mm | 25.5mm | 2.4mm |

| 31mm | 40mm | 2.5mm |

| 48mm | 60mm | 2.5mm |

How Do You Apply Rubber Grommets?

In case you want to apply rubber grommets to fabrics, then this involves a whole procedure.

It starts from applying interfacing to the fabric, assuming you need to make it tougher.

Metal grommets can at times tear out of textures, which is why rubber grommets can avoid the trouble.

Lay the fabric on a board with the back or side looking up.

Now place the fusible side of the interface onto the fabric or texture, then, at that point, try to squeeze fabric on top of it.

Then you need to apply pressure on the fabric with a hot iron for 10 to 15 seconds.

Select where you’ll apply the rubber grommet and place a spot under it.

In case you’re installing more grommets on fabric, mark the area for that grommet on it.

This leaves an equivalent space for each of them.

Then mark with circle, using a pencil at the center of the rubber grommet.

Make a hole in your texture or fabric utilizing a slot shaper.

Spot the slot shaper over the imprint you made on your fabric, and set it up so that you can hold it tight in your hand.

Now use some force to poke a hole in the texture.

You might have to strike the slot shaper more than once.

Set the rubber grommet on blacksmith iron, so that you can slide it through central hole in the fabric.

Spot the blacksmith’s iron on a level first.

Now slide the fabric slot over the rubber grommet at its peak.

Slide a washer at the top of rubber grommet after making a point to slide it easily.

This washer doesn’t need to be at the highest point of the Grommet; it totally should be secure enough that it will not slide off.

Utilize a mallet, pound these 2 pieces together and then spot the adjustable piece over the top of washer and grommet.

This allows the adjustment for the blacksmith’s icon under the texture.

Hit it with a hammer, then you can tilt the setter a bit to a quarter turn to hit it once more.

Continue to strike more so that the washer and grommet are solidly joined to one another.

Another easy procedure of applying rubber grommet is by using the Grommet stretching tool, and it can be done in an easy way.

- Put the rubber grommet at the end of your Grommet Stretching Tool.

- By using the handle, you can squeeze it gently to spread the rubber grommet.

- Then, you can use the cable or wire to insert it through the rubber grommet and then leave the tool handle.

- Then, you can remove it from the grommet stretching tool by sliding it off from the ends.

Are Rubber Grommets Waterproof?

Rubber grommets have great resistance properties, which is why they are very good resistors to water.

Rubber grommets are a sort of frill of the wiring gear too.

![]()

The objective is to protect the cables or wires from being cut at any point by sharp edge cuttings.

This also allows the object to become dustproof and waterproof.

These rubber grommets have waterproof properties, which is why they are extraordinary for car, marine, rough terrain, and sporting vehicle applications.

The rubber grommets are utilized to seal the hole that is recently made, and they give safety from water and residue.

All the rubber units are waterproof, which is why you don’t need to add an additional layer for safety and assurance at any point.

How Do You Remove Rubber Grommets?

Rubber grommets are stretchable products, and sometimes they can be tricky to remove from any point.

Removing the rubber grommet is not very difficult if you know how to do it.

Removing rubber grommets can make it hard to be removed and introduce the next Grommet.

So you can remove the rubber grommets with these easy steps.

Getting to the Rubber Grommet

First of all, to start with, you should access the rubber grommet, which may be the hardest part.

In case that the Grommet is in the engine of your vehicle or in a hard drive, reaching it tends to be somewhat troublesome.

The main thing to recollect here is to not apply force on your hardware while attempting to locate it.

The last thing which you need to do is harm the tool or component that you are dealing with while looking for the old Grommet.

Utilize A Screwdriver

After you have located the rubber grommet, you have to eliminate or remove it.

There are two essential approaches to eliminate a rubber grommet, and each relies upon what the Grommet is being utilized for.

In case that your Grommet is being utilized in an outside application, then you can use a screwdriver to remove it easily.

Stretch the rubber grommet by pushing its one side with a screwdriver and getting it on top of the nip of a screwdriver to pull it off.

Cut The Rubber Grommet

In case that it is not possible to remove it with a screwdriver, then you have to cut it.

When the rubber grommet is situated on the inside of an application medium, where it’s hard to reach, then cutting is the only solution.

In an electronic gadget, you might have wires or different parts going through it, which is why you need to be careful.

So you have to cut the rubber grommet in order to remove it nice and slowly and apply a new one on that surface.

You can get a new rubber grommet for your product from Baiwesilicone at reasonable prices and also bulk orders from China.

How Do You Stretch Rubber Grommets?

The rubber grommets can be stretched if you have the right tool, such as Grommet Stretching Tool.

- Use the Grommet Stretching Tool to put it up with the rubber grommet you want to stretch.

- By using the handle, you can squeeze it gently to spread the rubber grommet.

- Then, you can use the cable or wire to insert it through the rubber grommet and then leave the tool handle.

Can You Use Rubber Grommets On Fabric?

Rubber grommets can be used on fabric.

These grommets are awesome for fabrics that brawls or tears without any problem.

Lightweight materials like fabric require rubber grommets.

Rubber grommets are used on fabric by a whole process.

It starts with cutting from one side of the rubber grommet with a disposable cutter or sharp blade.

![]()

It makes it able to be folded with a hole grommet over the wire or tubing.

Then silicone sealant is applied along with the cut and pressed together tightly.

When it dries, it holds the Rubber in a position as an encased article.

Then installation of rubber grommets on the fabric takes place.

It starts with drilling the hole for the Grommet to be embedded into.

A power drill is used to penetrate and make a hole according to the suggested size.

Then utilizing a handheld deburring tool, the hole is smoothened down before embedding the Grommet.

Then start to push the rubber grommet from one side to the other in a round circle.

Approach the contrary side of the hole by applying force in a sequence that will allow the rubber grommet to set well in the hole.

Do Chinese Manufacturers Offer Custom Grommet Design Service?

Baiwesilicone is the best Chinese manufacturer that offers custom grommet design services for customers.

The customer can order custom rubber grommet designs from this company in bulk, and the stock can be shipped to other countries as well.

What Is The Quality Of Chinese Rubber Grommets?

The quality of Chinese rubber grommets is good as compared to European market.

They provide a good quality in less price because all the raw materials are sourced within the country.

You can have a few checks before buying:

- How much experience do they have?

- What is the price?

- Which material do they use?

- Delivery time

- Which certifications do they have?