Advanced Equipment Rubber Bush Factory

As one of the trusted and professional rubber bush manufacturers and suppliers in China, Baiwe ensures full support and provides effective solutions. In more than 15 years, Baiwe handles improved quality products and services.

Baiwe is the best partner to rely on, especially when needing support for your own brand. Send your specific details now! We will give you the best price offer.

The best performance, tested, and proven anti-vibration rubber bush is a guaranteed international certified product. Durable rubber bush for excellent service.

We fully support automotive rubber bush applications ensuring certified and easy to install. It has a great appearance and features for long-life service.

Choose one of the popular colors of rubber bush and many related products for different applications. We can produce your desired quantity.

We manufacture rubber bush for captive cab mounting applications. Different colors, shapes, and more to meet your special needs.

We can custom rubber bush for your final applications and business demands. We will produce the best quality, features, and suitable specifications.

According to your final applications, we can make your ideal sizes perfect for automotive purposes, which are negotiable and affordable for saving money.

Send your ideal rubber bush applications. We manufacture different colors and able to custom your own colors according to your needs.

We manufacture rubber bush for engine mounting purposes. We produce shapes and sizes according to your request made with durable raw materials.

For gearbox mounting applications, rubber bush is a more useful product with great performance at a very affordable cost to help your growing business.

Get the best selections and ensure to produce all your business needs by choosing the right sizes, shapes, features, and more at a cheaper price.

The best anti-vibration rubber bush is applicable for vehicle purposes. A perfect insulator with a variety of sizes and shapes that you can choose.

Vehicle suspension applications of rubber bush can ensure to minimize vibration and noise. We manufacture easy to set up and long life span.

Baiwe: One-Stop Solution Provider For Your Rubber Bush Project

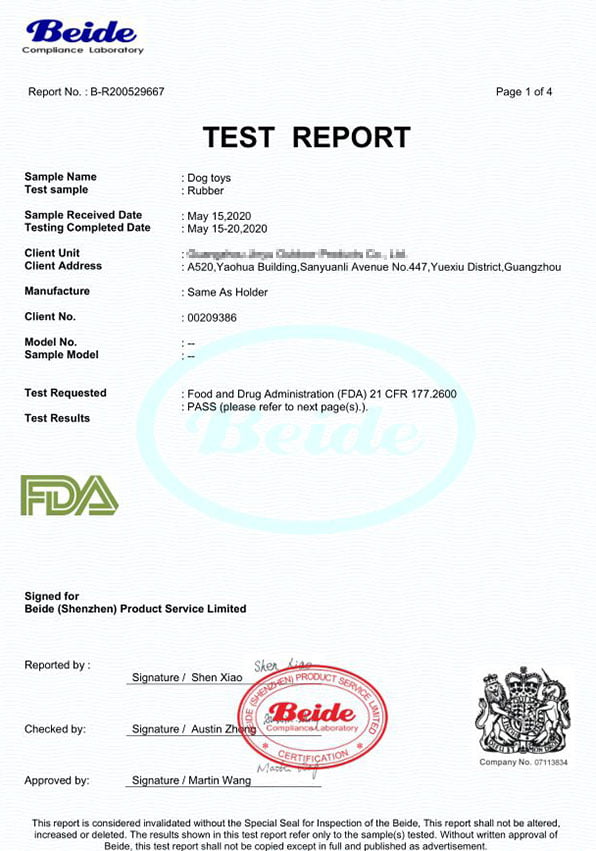

Choose the right rubber bush manufacturer and producer to meet your business demands in China. Baiwe handles silicone rubber products fabrications like kitchenware, baby products, and more. Our rubber bush is an SGS and FDA approved that support all types of selections.

As your leading rubber bush producer, we will assure a certified and cost-effective offer. Baiwe can custom your rubber bush desired sizes, colors, applications, and more. We handle complete service from manufacturing, sales, deliveries, and more.

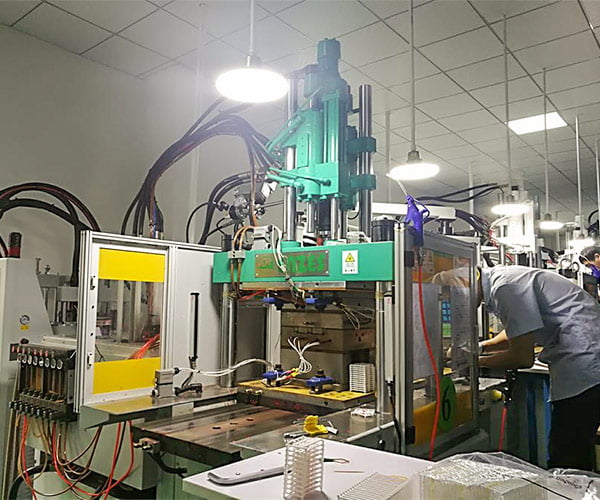

- Manufacturing

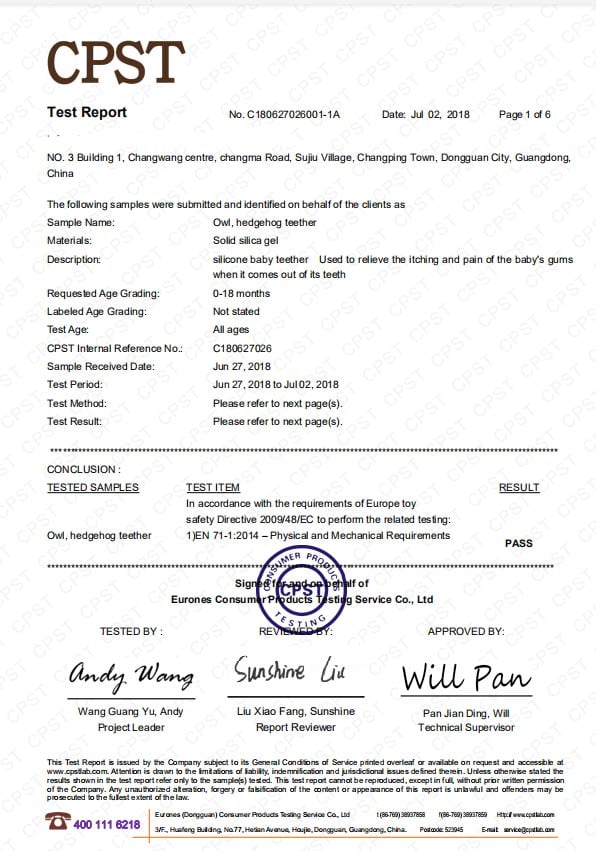

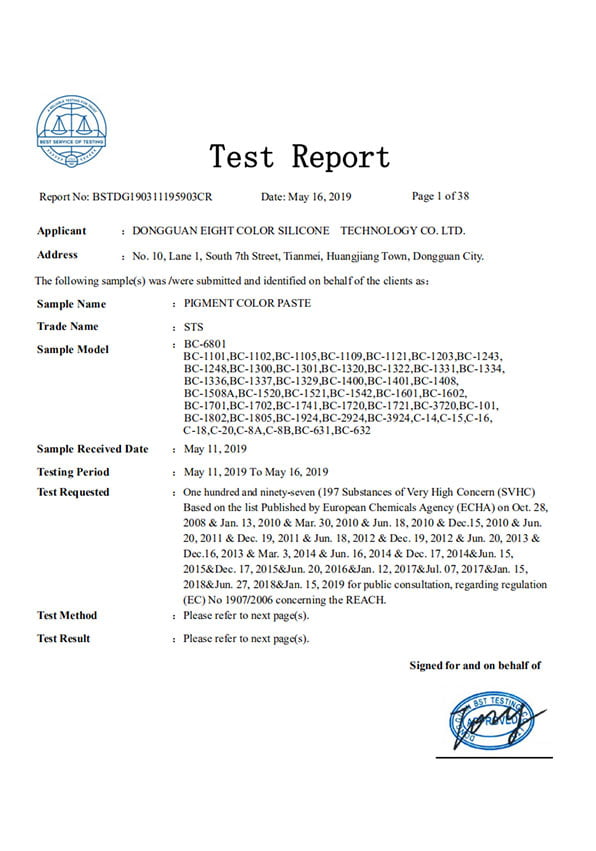

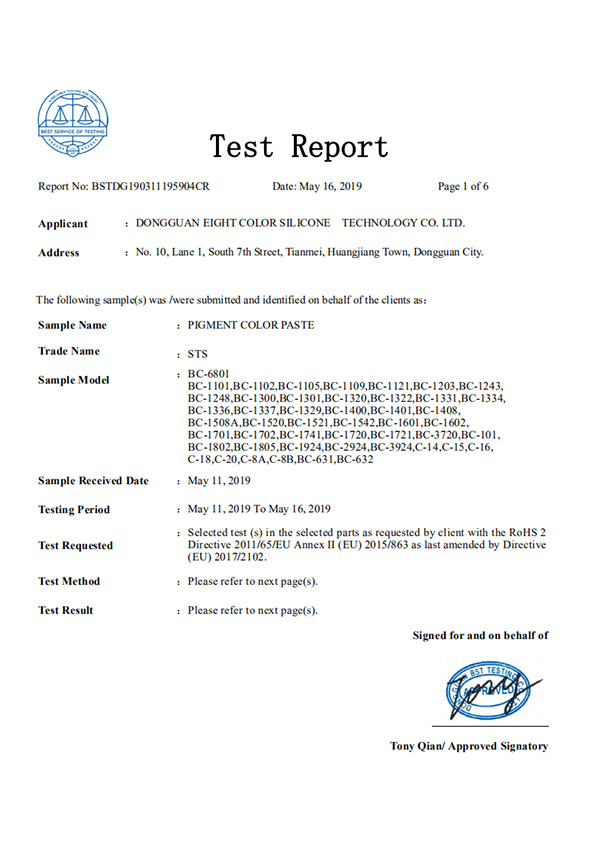

- Certifications

- Top Quality Control

Baiwe Rubber Bush

Searching for a trusted and responsible partner for your rubber bush orders? Well, Baiwe is one of the great producers and manufacturers in China that will handle the rest of your worries. We have a reach of experience providing one-stop solutions for your rubber bush orders.

Rubber bush is a vibration insulator that interfaces two parts and limits each movement to lessen the noise caused by vibration. We manufacture a variety of forms that eliminates two parts of lubrication. It is widely used in-vehicle applications.

Baiwe rubber bush is commonly applicable for anti-roll bars, suspensions, mountings, and more, aside from vehicle applications. You can consider advantages and different functions as well. It can be a shock absorber, resistor, and vibration insulator. We have complete sizes from standard to custom sizes according to your needs. It has a great appearance and features that support long service.

The rubber bushing is applied with wires, tubes, and pipes that complete fabrication and more. You can get perfect sizes, colors, features, specifications, and more that can meet your final application needs.

Rubber bush has a variety of functions that fit different applications. We will custom according to your final applications. Engineer offers custom anti-vibration for your different applications and purposes. We will find the best solutions.

Whether you need rubber bushing for your personal project applications, retail and wholesale business, and more types of purposes, Baiwe will be a great choice for you. We ensure the best quality products and assure you of strict quality inspection before delivering to your location.

In more than 15 years in service, we gained amazing customer’s trust and get their repeat orders because of product durability, quality, and cost-effectiveness. We will fully support your expandable business and produce negotiable rubber bush.

Send your inquiries. We offer a faster response and satisfying customer service for you. Get in touch now!

Rubber Bush – The Ultimate FAQs Guide

Are you wondering how important rubber bushes are in the automobile industry?

Confused about how they work like shock absorbers in different areas of vehicles?

Rubber bushes may raise several questions in your mind. Therefore, you should read this guide to clarify your doubts.

Let’s get started.

- What Is Rubber Bellow?

- What Are The Other Names For Rubber Bellow?

- What Are Bellow Boots Used For?

- How Rubber Bellows Are Manufactured?

- What Does A Rubber Bellows Boot Cover?

- What Component Does A Rubber Bellow Boot Protect?

- How Many Bellow Boots Does A Rack & Pinion Have?

- What Are The Different Types Of Convolutes Used In Molded Rubber Bellows? And What Are Their Advantages?

- How To Determine The Best Length Of Travel For Rubber Bellow Boot?

- What Are The Best Ways To Secure The Both Ends Of The Rubber Bellow?

- What Is The Role Of Envelops On The Rubber Bellows?

- What Are The Different Types Of Rubber Materials Used To Make Rubber Bellows?

- Do Rubber Bellow Manufacturers Offer Customization (OEM)? And What Is Their Requirement?

- What Is The Structure Of Rubber Bellow?

- What Is The Purpose Of Holes In Rubber Bellow’s Base?

- What Are The Applications Of Rubber Bellow?

- Which Rubber Bellow Do I Need?

- Custom Rubber Bellows And Boots Provides Protection Against What Thing?

- What Are Different Profile/Shapes Of Rubber Bellows?

- What Is The Average Life Span Of A Rubber Bellow?

1. What Is A Rubber Bush?

A rubber bush is a vibration isolator in different parts of vehicles.

Mainly, it helps in maintaining limited movement between two metallic parts while separating them.

In this way, vibration or unnecessary sounds are minimized to enough levels.

Moreover, it acts as an interface between two parts of machinery and absorbs transmitted energy.

In cars and other vehicles, they can suddenly manage the uncontrolled movements when vehicles are near to meet an accident.

The elastic properties of rubber bushes permit automobile suspensions to absorb sudden jerks.

And so, they are efficient at maintaining parts of engines while blocking harmful heat energies and vibrations.

![]()

2. What Are Rubber Bushes Used For?

Rubber bushes have wide use in shock absorbers of automobiles.

Rubber as their constituent particle makes them a useful product in large areas of the automobile industry.

Among their many uses are anti-roll bars, shock absorber mountings, generation resistors in metallic machinery as they can isolate them and save them from technical harm.

Skateboards are also equipped with rubber bushes while tilting trucks and turning boards.

They are highly effective at reducing friction and vibration.

They are helpful products for maintaining stress and high loads of goods while transferring them from one place to another.

In pipes or tubes, rubber bushes can serve the duty of sealing or be used as joints.

Their main use occurs as an insulator for vibration, and so they can be used in all machinery parts where a soundproof gadget is needed.

3. What Are The Advantages Of Rubber Bushes

There are many advantages of rubber bushes; some are listed below.

● Provide Enhanced Safety

Getting rubber bushes can enhance the safety of vehicles.

Rubber has excellent alignment properties, so you can gain a strong grip when used on steering wheels.

Furthermore, rubber cannot break when expanding, so it can resist temperature changes.

However, rubber bushes need to be in good condition to provide maximum safety.

● Reduce Damage By Absorbing Vibration

Automobile engines can suffer damage from vibrations of moving parts.

Extra movement weakens their machinery, ultimately causing wear and tear.

This is why rubber bushes are used since they can absorb a great deal of vibration.

By doing so, the movement of metallic parts is limited, and damage is less likely to occur.

● Wide Use For All Types Of Vehicles

Since they can fit any vehicle, they are highly valued. Almost every type of vehicle can be equipped with these.

A product like this is a great addition to all the mechanical components of automobiles, including gears, joints, and pivotal arms.

4. What Are The Qualities Of Rubber Bushing

Rubber bushes have excellent qualities that make them valuable for the automobile industry. They are listed below;

● Sound Absorbing Quality

Sound absorption is the most important quality of rubber bushings.

Due to this quality, it is used in combustion and shock-absorbing components of machinery.

The rubber is the best noise control product and makes bushings useful as an insulator.

● Stress Bearing Ability

Rubber bushings can increase the strength and durability of any component as they are capable of bearing stress.

Rubber’s elasticity allows it to be fitted with different metal components and provide strength in different directions.

● Friction Reduction

As rubber is a perfect insulator, it can reduce friction by absorbing any negative energies.

In this way, it increases the life of mechanical components by saving them from extra rubbing.

Moreover, vibrations at high frequencies are limited by using these bushes, which reduces friction.

If you are looking for high-quality rubber bushes, then Baiwesilicone is a go-to choice, which has an experience of about 15 years of experience.

5. What Are Different Types Of Rubber Bushes?

There are different types of rubber bush depending on the structure and area of use. Several of them are described below.

● Control Arm Bushes

A control arm bush is attached to the frame and arm of a vehicle. Consequently, they are highly effective at reducing friction and vibration.

These elements’ main function is to control the wear and tear of tires on the road while the vehicle is in motion.

![]()

● Flanged Bushes

A flange bush is a sleeve bearing that has a “flange” or shoulder on one end. There are many functions for the flange.

This can aid in the mounting and alignment of the bearing. In addition, it facilitates layer installation.

● Pivot Bushes

The purpose of pivot bushes is to provide the minimum amount of torsion resistance.

An extremely low torsional resistance can be achieved by securing the elastomer between one arm and a permanent lubricant.

● Spherical Bushes

The Spherical Bushings are small and heavyweight flexible.

They can endure very high loads and accommodate torsional as well as conical movement.

In contrast to typical bushings, no lubrication is necessary for the Spherical Bushings, and maintenance is minimal.

They are appropriate for different applications, for example, vehicles off-road, building equipment, and applied rail.

6. How Long Do Rubber Bushes Last?

The average life expectancy of rubber bushes is 15 to 20 years.

It has been found that rubber bushes typically last as long as rubber does.

But environmental changes can shorten the life expectancy of rubber and so the rubber bushes.

Rubber does not break easily; however, it can degrade when exposed to ozone.

Some rubber bushes that work in combustion engines of vehicles can relatively be worn out more quickly by constant heat.

The case is different for rubber bushes that are designed to bear loads. Their degradation does not depend upon the amount of time but on the amount of load.

Higher loads make these bushes weak, and so they may not work longer.

Automobiles and cars are affected more by distance traveled than by time.

That’s why the bushes used in control arms and trailing arms cannot work efficiently after their 50,000kms of traveling. This case is more likely to occur in heavy cars like BMWs.

After some time, rubber over bushes becomes hardened or rotted, but it may not cause any safety or technical issues.

However, it results in a stiffer ride, which is appreciated by some people.

The bushes can work perfectly until they get completely worn out, which in some cases depends on time or sometimes on their workload.

![]()

7. How Are Rubber Bushes Made?

The following steps are involved in making rubber bushes.

Step 1: Rubber extruders in Baiwesilicone are used to make any rubber extruded items.

Step 2: Raw rubber material, sometimes called stock, is collected and stored by extruders.

Step 3: During loading, the stock is transferred from hopper to channel.

Step 4: A long screw is used to push the stock down when an extruder’s transmission channel spins.

Step 5: Furthermore, the stock is pushed and transformed into a semi-liquid state.

Step 6: Following proper preparation, the stock is ready to die. In raw materials, a die serves as a tool for transforming them into usable items.

Step 7: Rubber that has just been extruded from the die will harden as it cools.

Step 8: Extruders can either be cut or transported in their current condition or undergo more processing as needed.

8. Where Is A Rubber Bush Used In Plumbing?

A rubber bush can be used in plumbing by coupling it with pipes.

You can use it while connecting a pipe to a component having a different diameter than the pipe.

Rubber bushes also solve the problem of an increase or decrease in the size of pipes.

It is due to their availability in a variety of sizes and shapes.

Rubber bushes are effectively suitable for specific applications in plumbing, one of which is the sealing of pipes.

The rubber elasticity enables bushes to be molded in any shape according to need and fit size while sealing any leakage or open end in pipes or tubes.

Their general use in plumbing is by coupling it with different pipes for various purposes.

An underground drainage system can provide watertight connections for any chemical resistance due to their isolation ability.

These bushes are also robust while dealing with concrete or clay pipes as you don’t need any adhesive for their installation.

Their small size, lightweight, different alignment flexibility, and weather resistance are cars due to great use in the plumbing field.

![]()

9. Which Type Of Rubber Is Used In Bushings?

The rubber used in manufacturing rubber bushes is natural rubber called polyisoprene. But it is made with alternative elastomers and different grades.

Neoprene is also common in the making of bushings.

Neoprene is like rubber, but with its qualities, it is an entirely different substance.

There are over 200 species of plants and trees used in the manufacture of latex rubber.

Comparatively, Neoprene is a synthetic substance made by polymerizing chloroprene.

Despite the technical terminology, Neoprene is an ideal material for bushings as it is tougher and stronger than rubber.

Rubber is sensitive to heat, whereas Neoprene can resist temperatures as high as 200 degrees. Contrary to rubber, Neoprene will not degrade when exposed to oil.

This rubber formulation has a high heat strength, excellent anti-air aging properties, moderate hardness, and a good stress rate. The metal and material rubber are combined with a damping drill.

The load capacity of a rubber section is high and good in mechanical properties; product quality is improved for shock-absorbing ability.

![]()

10. How Does Rubber Bushing Work?

Rubber bushings work by expanding their rubber. The car has suspension at various points.

The suspensions of the car have to move up and down whenever the engine is running.

While doing so, they produce vibrations, which are transferred to the cabin of the car. This vibration makes a lot of noise and harshness in the car.

Here comes the use of rubber bushings. They serve as a connection between suspensions and cars. In this way, the vibrations and noises are isolated from the cars’ cabins.

Here The actual work performed by rubber bushings is like a shock absorber. It absorbs extra movements, when used on steering wheels ultimately protecting engines and metallic components.

Without the use of rubber bushes, the engines of vehicles cannot work properly. Otherwise, the serenity of cars would be disturbed.

11. How Often Do You Need To Replace Rubber Bushings?

You should go for bushing replacement when the rubber becomes very old and worn out.

It is necessary that once in a car’s life, you should replace all the bushings. Bushes are designed according to the lifespan of a car, which is 15 years.

But it is much better for safety and car functionality if you replace them once in a car’s lifetime.

With time, rubber dries up and becomes hard due to the effect of oil leakage and temperature. This hard rubber can not absorb noise, and so it will be of no use for damping.

If your cars or vehicles start showing irritating noise and unbearable vibration, you feel a clear difference from previous peaceful rides.

It is a sign that your bushes need to replace bushes. When rubber is completely worn out, the isolation of metal from the metal finishes, and they come in contact.

It produces friction which can negatively impact the engine and decrease the lifespan of the vehicle.

Usually, we do not pay attention to such small components in our cars.

But these parts should not be neglected. Some difficulties we face during our rides, such as excessive engine heat up or constant vibrations, are due to these worn-out parts.

12. Do You Need To Grease Polyurethane Brushes?

Yes, there is a need to grease polyurethane bushes.

Greasing is necessary for the proper optimization of polyurethane bushes.

Polyurethane bushings are good for longevity and performance, but they need to be timely maintained to keep them quiet and in perfect condition.

Nothing degrades polyurethane bushings or harms them, but sufficient rubbing can destroy them without suitable lubrication.

Greasing will allow polyurethane bushings to function correctly and will work for your vehicles.

Greasing is waterproof and provides greater protection to rubber bushes. Greasing can be a proper solution if your vehicle engine is making extra noises and you don’t have new bushings meantime.

![]()

13. Which Lubricant Is Best For Bushing

Silicon-based lubricants, white lithium, or a special rubber lubricant are the ideal lubricants for drying rubber.

These different types of lubricants should be found in any engine goods shop.

Even polyurethane bushings should be lubricated with oil-based when used on steering wheels.

Silicon grease makes rubber soft and enhances its absorbing quality. They are waterproof and protect rubber and non-metal surfaces.

You can also get a silicone lubricant spray which is easy to use and can be done easily when needed.

![]()

14. How To Choose The Right Rubber Bush From China?

By reading following steps you can choose a rubber bush manufacturer that is right for you;

Step 1. Analyze The Quality Of Rubber

Choosing the right rubber bush from China is not a big deal unless you completely know about analyzing rubber bushes’ quality.

Step 2. Know About The Purpose Of Purchase

As rubber bushes come in a variety of sizes and shapes, so before going to find a manufacturer, you should know for which purpose you are buying rubber bushes.

Step 3: Research on Google

The next step is to find the best manufacturer of rubber bush in China.

You can use Google as a primary searching platform.

Although there are many rubber bush manufacturers in China, not all of them can provide better service quality.

Cheap quality rubber in bushes can destroy your vehicle’s engine and wear out after some time.

Step 4: Seal the deal with the Right Manufacturer

You should be careful while choosing the right rubber bush manufacturer.

In China, Baiwesilicone, with experience of over 15 years, is a familiar and professional rubber bush supplier. They are one of the top-rated manufacturers of rubber bushes in China.

Their quality products include rubber bushes of all types, silicone sleeves, silicone medical parts, and many other silicone and rubber toys.

![]()

15. Do Chinese Manufacturers Produce Good Quality Rubber Bushes?

Yes, Chinese manufacturers produce high-quality rubber bushes.

They handle rubber bushes efficiently, and then they provide high-quality products to your location when you need them.

It is Baiwesilicone which manufactures the best rubber bushes among all Chinese suppliers. By providing long-lasting services based on their extensive experience, they can bring value to your business.

Their skilled team can understand your requirements and provide you with rubber bushes to meet your specific needs.

Their team of experienced designers will provide you with 3D drawing design, which is a common bonus that not all manufacturers are able to provide.

![]()

16. What Is The Process To Order Rubber Bushes From China?

The step-by-step process of ordering rubber bushes from China in bulk amounts is given below.

● Know About Your Legal Rights

The first step in ordering rubber bushes from China is to know about your legal rights. Every country has its own legal rights.

Legal rights are different for every country and depend upon specific security numbers.

These legal numbers can tell you about your eligibility, whether you can import rubber bushes from China or not.

● Make Sure That You Are Allowed To Import Rubber Bushes

Not every product is allowed to be imported in every country. Different countries have their own rules for prohibited products.

As we are talking about bulk quantities, you should make sure you order rubber bushes from China to your country. Therefore, you should not ignore this factor.

● Calculate Landed Cost After Classification Of Product

For each item you are importing, specify the 10-digit tariff classification number.

Together with the Certificate of Origin, these numbers are used to establish the duty rate paid when importing. Then you calculate the cost of the land.

Before placing your order, be careful about the Income terms and compute the total landing cost. The next three together are, for example, added by FOB.

● Get The Company’s Product Pricing

Ask the agent for shipping costs (if it is to door shipping, that will be sufficient)

Get customs processing, tax, transportation to the warehouse from the landing.

● Find And Place An Order For Your Supplier In China

Place your order with the seller, sender, or exporter to determine the delivery conditions to be used.

After selecting your supplier, you will be asked to submit a P/I (Proforma Invoice or Quote Sheet) with the network number, description, and value per item in the harmonized system.

The weight, packing size, and purchase term must be displayed for your P/I.

● Arrange The Transportation Of Your Cargo

Shipping products, including container charges, packaging, management of terminals, and broker fees, include many costs.

Each of these aspects should be taken into consideration to some people appreciate gain a complete picture of shipping costs. Ensure that your shipment is fast and safe. ![]()