Moulded Rubber Bellows Factory

Baiwe is a rubber injection molding company in China, with experts in producing rubber products. We utilize compression, transfer, and injection molding to make high-quality moulded rubber bellows. Being one of the best moulded rubber bellows manufacturers, we can help you process selection, and molded bellows in various sizes. We perform rubber-to-meal-bonding and die-cutting for set rubber bellows production. Please send us your inquiry!

Baiwe Rubber Bellow Cover Telescopic is highly customizable as per request. You can send us your product requirements, such as your 2D or 3D drawings.

It has EPDM exhibits with hot and cold water, fireproof hydraulic fluids, and alkalis. It also exhibits unsatisfactory compatibility with most oils, gasoline, etc.

They are applicable in auto, machinery, air condition, valves, toys, water pumps, pipes, coffee machines, etc. Our rubber bellows are accessible at affordable prices.

The product is customizable as per request. They are suitable for medical applications and can be available in many colors.

We can customize your ideal rubber bellows based on your designs, sizes, shapes, and other configurations. We can also put a logo on it for your branding.

The common usage for this product is to seal sand, dust, and other environmental elements from moving parts of machines. It also removes vibration between equipment.

We manufacture flexible Rubber NBR Bellows with advantageous features, such as fatigue resistance, anti-aging, great flexibility, anti-toxic, and good ventilation.

Actually, round-shaped rubber bellows are also available. No matter what, we can produce custom rubber bellows if you request at a very reasonable price.

You can find different designs, sizes, and other specifications for Dustproof Rubber Bellows. We are using high-quality raw materials for durability and high quality.

It can work as an expansion or cover joint to protect machines or devices. We realize rubber compression molding, extrusion tool, or rubber injection mold.

They are thermally stable, easy to fit, absolutely watertight, and can resist emulsion, mineral, or oil.

We ensure that you can get rubber bellows with great benefits. It features abrasion resistance, healthy aging, long-life, durable, low, and high-temperature resistance.

Baiwe: One-Stop Solution Provider For Your Moulded Rubber Bellows Project

We are your value-added moulded rubber bellows manufacturer in China, offering services such as design reviews, drawing development, prototyping, testing, and tooling. Baiwe has a complete supply chain solution through our packaging, inventory management, and worldwide shipping for moulded rubber bellows products.

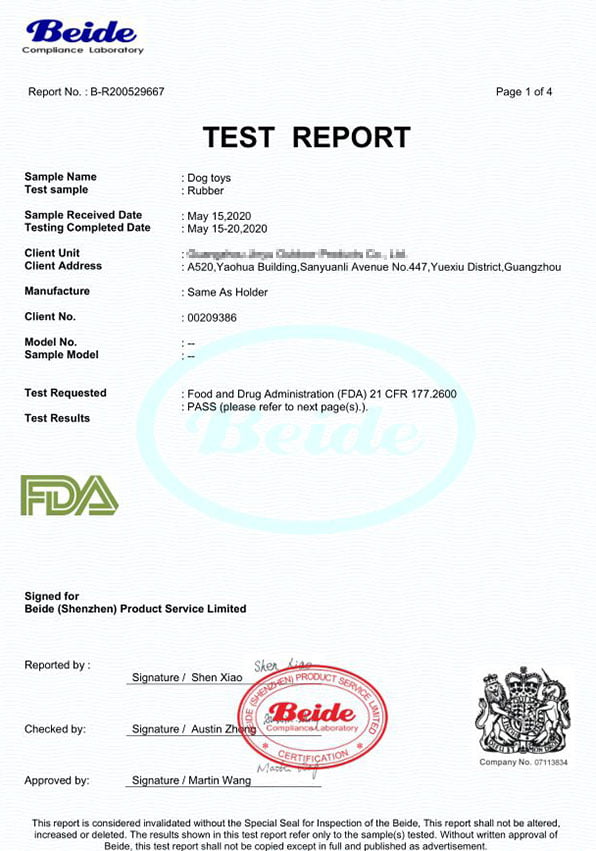

Our professional designer and skilled technical team use high-performance materials to produce custom molded rubber bellows that meet FDA, ASTM, UL, and military specifications. Baiwe is committed to improving our process, products, and systems according to external and internal inputs to meet our customer’s requirements.

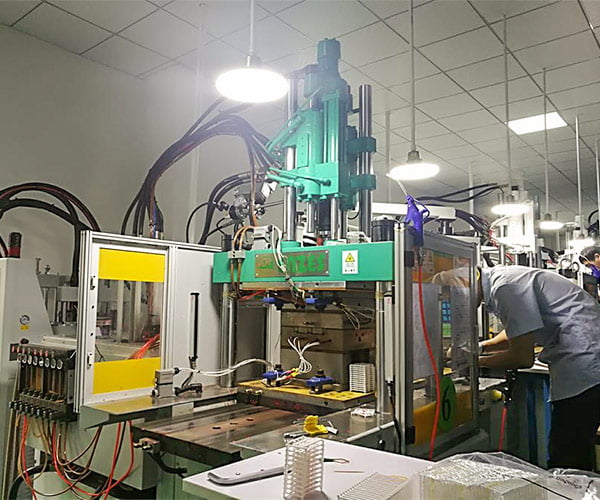

- Manufacturing

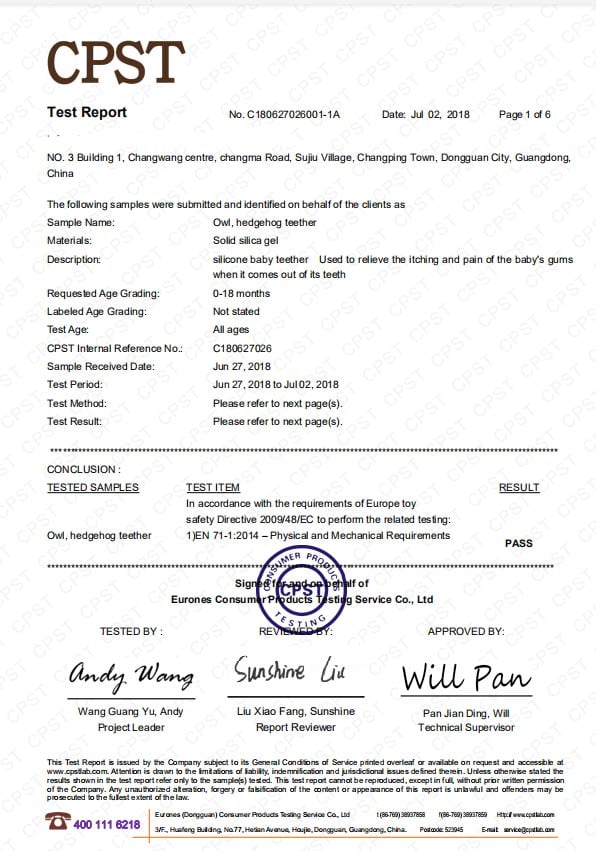

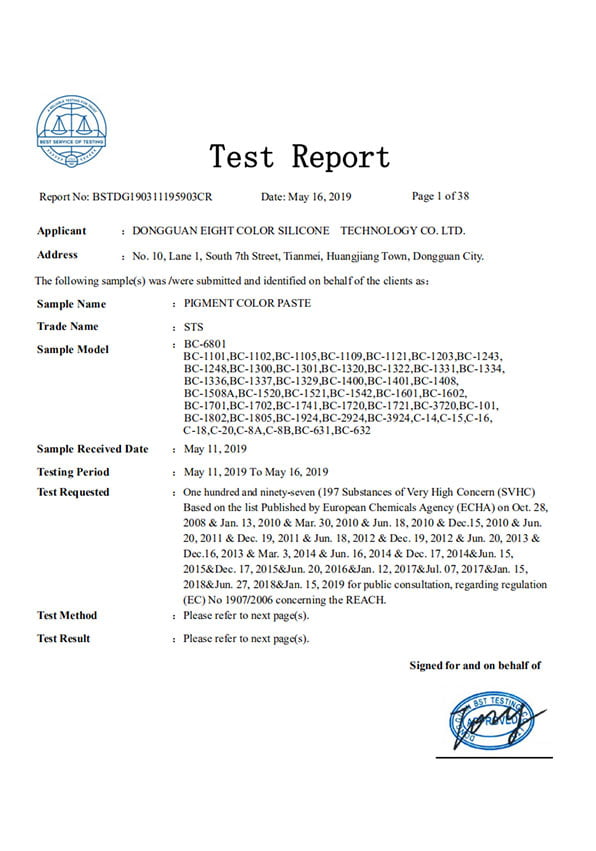

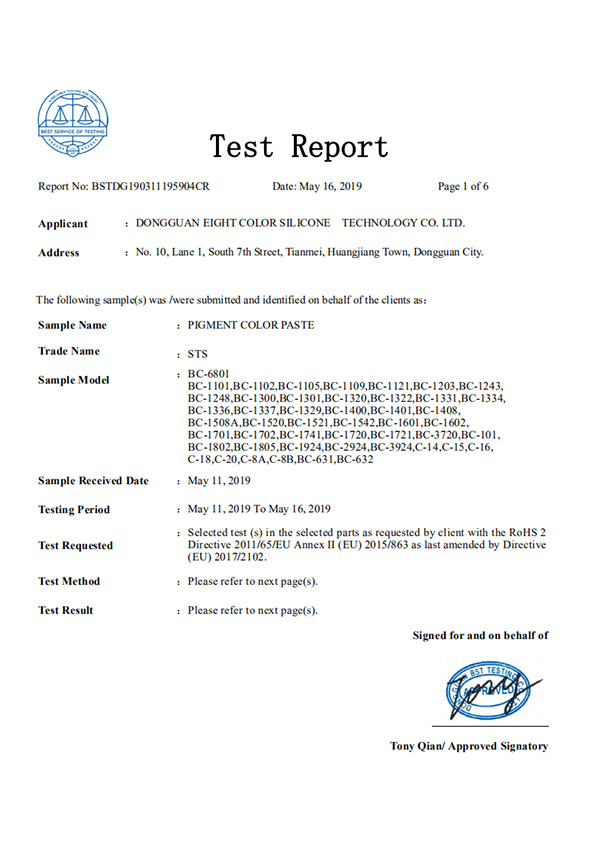

- Certifications

- Top Quality Control

Baiwe- Your Professional Moulded Rubber Bellows Manufacturer

A flexible seal moulded rubber bellows that permitting a range of motion can protect mechanical structures from the environment. It is applicable in transportation, industrial, and many other applications. The moulded rubber bellows can cover against water, dust, grease, chemicals, oil, and environmental elements like splatter, mud, and snow.

If you’re a moulded rubber bellows brand that needs to import for your business or project, Baiwe has a considerable solution. We are manufacturing moulded rubber bellows for over 15 years. Baiwe moulded rubber bellows ensure noise reduction, shock resistance, resist vibration, withstand ozone and sunlight while maintaining flexibility at changing temperatures.

Being the most trusted moulded rubber bellows producer, our team uses transfer, compression, and injection molding to create custom and standard moulded rubber bellows. We can offer you our moulded rubber bellows in a wide range of shapes, materials, and sizes.

Whether you need small or large diameter rubber bellows, Baiwe can mold quality rubber bellows for you. We, Baiwe, can accommodate all your needs regarding rubber bellows products. Besides, we can help you with material selection and offer value-added services like design assistance.

BAiwe is an expert in designing and manufacturing molds for any size and shape of rubber bellows. Most business owners and significant companies trust our expertise in designing moulded rubber bellows that protect and simplify end-product assembly.

Since the beginning, our company is committed to the customers’ satisfaction. We can guarantee extraordinarily durable and versatile moulded rubber bellows to meet your expectations.

All our moulded rubber bellows meet different industry standards and norms. Baiwe has complete certifications for all markets to offer you our best support, including EN71, SGS, Phthalate-free, and REACH197.

You can trust Baiwe, your trusted moulded rubber bellows manufacturer in China. Our quality controller strictly follows our quality control system to deliver trusted quality moulded rubber bellows to our customers from different countries.

If you’re interested in moulded rubber bellows, please don’t hesitate to call our one the sales engineers.

Rubber Bellow – The Ultimate FAQs Guide

If you are looking for rubber bellows, then this is the guide for you!

This guide will answer all your questions and give you a quick rundown on what exactly they are.

Along with that, it will also make suggestions of different types of bellows to use in different scenarios.

Whether you’re working with food or chemicals, there’s bound to be something here that can help.

So scroll down and enjoy this ultimate FAQs Guide on Rubber Bellows!

- What Is Rubber Bellow?

- What Are The Other Names For Rubber Bellow?

- What Are Bellow Boots Used For?

- How Rubber Bellows Are Manufactured?

- What Does A Rubber Bellows Boot Cover?

- What Component Does A Rubber Bellow Boot Protect?

- How Many Bellow Boots Does A Rack & Pinion Have?

- What Are The Different Types Of Convolutes Used In Molded Rubber Bellows? And What Are Their Advantages?

- How To Determine The Best Length Of Travel For Rubber Bellow Boot?

- What Are The Best Ways To Secure The Both Ends Of The Rubber Bellow?

- What Is The Role Of Envelops On The Rubber Bellows?

- What Are The Different Types Of Rubber Materials Used To Make Rubber Bellows?

- Do Rubber Bellow Manufacturers Offer Customization (OEM)? And What Is Their Requirement?

- What Is The Structure Of Rubber Bellow?

- What Is The Purpose Of Holes In Rubber Bellow’s Base?

- What Are The Applications Of Rubber Bellow?

- Which Rubber Bellow Do I Need?

- Custom Rubber Bellows And Boots Provides Protection Against What Thing?

- What Are Different Profile/Shapes Of Rubber Bellows?

- What Is The Average Life Span Of A Rubber Bellow?

What Is Rubber Bellow?

![]()

Rubber bellows usually consist of a sheet or pile of vulcanized rubber, which is bound between two sections.

When the sections are compressed, the rubber bends and stretches in much the same way as during molding.

Rubber bellows are used to create an airtight seal or cushioning for mechanical equipment, piping systems, and other structures.

Typically, rubber bellows are pliable enough that they can be compressed/popped back into shape after deformation (e.g., tapping).

It is these properties of rubber that make it widely utilized in sealing engineering applications like pipe hangers, vibration isolation mounting for motors and electronic equipment, automotive applications like gas tank baffles & door weatherstrips, etc…

What Are The Other Names For Rubber Bellow?

Rubber bellows are often referred to as rubber expansion joints, rack and pinion boots, and rubber boots.

They may also have different names according to their type, shape, and brand.

What Are Bellow Boots Used For?

![]()

Unlike other products, rubber bellows are often employed in industrial and automotive applications to protect against dust or light-duty environmental factors.

They have a variety of different uses, such as:

- Being used for sealing out air while allowing specific strokes from an engine’s valves on car parts (filters);

- Protecting electronics by blocking fluids leaking past them when they’re not installed correctly – sometimes even acting like drag rugs at race tracks!

A similar use would be expanding joints found within structures where it connects two pipes together, so water doesn’t escape into spaces you don’t want to be flooded over time.

How Are Rubber Bellows Manufactured?

There are numerous method to manufacture rubber bellows, some of them are as follow:

- Injection Molding: Best for manufacturing rubber bellows with different materials in varying sizes, thicknesses, and shapes.

- Compression Molding: Best for manufacturing rubber bellows with different materials in varying sizes, thicknesses, and shapes.

- Transfer Molding: Best for manufacturing rubber bellows with different materials in varying sizes, thicknesses, and shapes.

- Latex Dip Molding: This method is perfect for producing rubber bellows with seamless and uniform wall thickness.

- RF welding from thin vinyl films or urethane: It is used to manufacture rubber bellows that can be made in any length, with varying strengths, weight, and flexibilities.

- Fabric Reinforced Method: It is a method that’s used to manufacture fabric bellows.

These require the additional strength and protection of rubber coating, which are common in industries such as aviation or auto racing, among others where it’s necessary for durability reasons.

You can also watch the following video for the Rubber Bellow manufacturing process:

What Does A Rubber Bellows Boot Cover?

![]()

The Rubber Bellows Dust Boot is environmentally friendly and effective protection for your equipment.

It’s widely used in applications requiring dust, moisture, or oils resistant to chemicals like UV rays from sunlight (which can cause fading).

This rubberized cover also provides a measure against other elements such as oil spills by preventing dirt particles from reaching the insides of machinery where they might be harmful!

How Many Bellow Boots Does A Rack & Pinion Have?

They have two rubber bellows, one on each end of the rack and pinion.

What Are The Different Types Of Convolutes Used In Molded Rubber Bellows? And What Are Their Advantages?

![]()

Following are the two main types of convolutes used in molded rubber bellow along with their advantages:

- Concentric Convolute: For motion that is both straight up and down or out-and-back, the best rubber bellows are those with concentric convolutes.

They’re easier for machines to mold in the first place so you can produce a more consistent product every time.

Moreover, these types tend not to lose much shape over time as they flex back and forth from being pressured by air against their walls (or vice versa).

- Spiral Convolute: For motion with any articulation to it, spiral convolutes are the best. They don’t kink or pop out of shape when bent in the middle – as concentric ones often do!

How To Determine The Best Length Of Travel For Rubber Bellow Boot?

Rubber bellows are available in two basic styles that the application’s constraints can accommodate.

The delta between peak and valley needs to have ample space, requiring more zones for deployment.

Conversely, if there is less ground surface available around an area, then smaller numbers of convolutes will suffice.

This direction may also work well when you’re trying not to take up too much room with your equipment!

Designers have to be very careful when designing the rubber bellows.

They need a lot of material between each peak and valley for it not to become distorted.

Otherwise, if one is stretched beyond its limit, they can easily buckle inward or, even worse-not return back into shape once pressure has been released from them!

What Are The Best Ways To Secure The Both Ends Of The Rubber Bellow?

The ends of the rubber below can be secured in numerous ways depending on the application and end section of the bellow. Some of the prominent ones are as follow:

- A rubber bellow with an extended straight section can be secured by the retaining bead and a hose clamp on both ends.

- A rubber bellow with a locking grommet feature on its ends can work best for connecting bellows into a panel or metal sheet.

- A rubber bellow with an integrated flange extending out beyond the convolutes with mounting holes can be secured using bolts.

- A rubber bellow being used to protect an up-and-down moving application can be left secured on its end.

What Is The Role Of Envelops On The Rubber Bellows?

![]()

Although rubber bellows are flexible enough to perform into any tight space, the outside constraints or envelops have a significant impact on their functioning.

Therefore, you must use the proper design of the rubber below depending on its external constraints.

A tapered rubber bellow is often used to accommodate mechanisms inside the bellows shaped like a taper.

A straight-style or cylindrical kind of bellows may be employed if space constraints exist outside. And the different number of convolutes dictates which peak OD corresponds more closely to valley form. Meaning the tightest outer limits require smaller pieces (smaller “block”).

What Are The Different Types Of Rubber Materials Used To Make Rubber Bellows?

Rubber Bellows can be manufactured from numerous kinds of rubber materials depending on their application:

- Ethylene-Propylene (EPDM): This rubber compound is relatively cheaper than other materials.

It has excellent flex fatigue and water swell resistance, as well UV and Ozone Resistance.

However, its oil and grease resistance is poor. Nevertheless, it can easily withstand the temperature between -60F and 300F.

- Nitrile (NBR): This rubber compound is relatively cheaper than other materials but a bit costlier than EPDM.

It can withstand the temperature between -30F and 250F.

NBR has a fair amount of flex fatigue and poor Ozone and UV resistance.

However, its excellent resistance to water swelling and petroleum-based oils and hydrocarbon fuels makes it perfect for many rubber bellow applications.

- Neoprene / Chloroprene (CR): It is one of the inexpensive materials with excellent flex fatigue and fairly good Ozone and UV resistance.

However, its resistance to water swelling, oil, and grease is not that impressive.

Nevertheless, it can withstand temperatures ranging between -60F to 220F, making it perfect for FDA applications.

- Silicone (VMQ): This rubber compound is relatively expensive than most other materials.

However, it has excellent flex fatigue and water swell resistance, as well UV and Ozone Resistance.

However, its oil and grease resistance is low compared to others.

Nevertheless, it can easily withstand temperatures between -175F and 450F, making it perfect for medical and aerospace applications.

- Fluorocarbon (FKM): This rubber compound is relatively expensive than other materials.

It can withstand the temperature between 5F and 390F.

FKM has a fair amount of flex fatigue.

However, its excellent resistance to water swelling and petroleum-based oils and hydrocarbon fuels, as well as Ozone and UV, makes it perfect for many rubber bellow applications.

Do Rubber Bellow Manufacturers Offer Customization (OEM)? And What Is Their Requirement?

Yes, a reliable manufacturer like BaiweSilicone offers complete product customization to their client.

However, clients are encouraged to fulfill the following requirements for best results:

- 2D/3D design file, samples, ideas, or details for your requirement. In case you don’t have them, you can also request the manufacturer for their assistance.

- State your material demands such as Silicone, Nitrile, Chloroprene, etc. Or you can state your application requirement to the manufacturers for the best recommendation.

- Besides material requirements, you must also define its class, such as food-grade, medical-grade, industrial-grade, flame-retardant materials, etc.

- Describe your working environment to your manufacturer where custom rubber bellow is to be used. For example, it can be working temperature, chemical environment, etc.

- Define your harness demand. It can range between 10 and 80 Shore A (Durometer).

- Order Quantity and Annual Order Quantity.

What Is The Structure Of Rubber Bellow?

![]()

Rubber bellows can be engineered in many structures to meet various application requirements.

The most common structure is composed of either of two connecting parts and an expansion region these components provide the assembly interface.

Or one piece that fits over another like lips on either side. For example, when it needs less movement between design features.

This type might not always have much volume, though, so make sure you know what your specific situation demands!

What Is The Purpose Of Holes In Rubber Bellow’s Base?

The purpose of Holes in Rubber Bellows is Ventilation.

Ventilation is an important design feature to prevent pressure or vacuum conditions when the rubber bellows are actuated in many applications.

In many cases, ventilation can be accomplished by adding breather holes into your system below ground level and above it with something like an insulation board.

This will allow exhaust airflow while preventing other potentially dangerous substances from entering through these openings.

What Are The Applications Of Rubber Bellow?

Rubber bellows have plenty of applications in numerous industries. Some of them are mentioned below:

- HVAC

- Ventilation

- Automotive

- Expansion Joint

- Motion Coupling

- Petrochemical

- Semi-Conductor

- Pipe Expansion Joints

- Aerospace

- Heating

- Air Conditioning

- Marine

- Chemical

- Electrical Contacts

- Fluid Coupling

- Pharmaceutical

- Power Generation

- Gas

- Water

- Food

- Construction

Which Rubber Bellow Do I Need?

In order to determine the right rubber bellow for your application, it is best to contact the manufacturer’s representative.

A reliable Manufacturer like BaiweSilicone has the most competent team to analyze your application and recommending the best according to it.

What Are The Advantage Of Using Rubber Bellows And Boots?

Rubber Bellows and Boots provides numerous benefits to its application. Some of them are as follow:

- They are used as extension joints to remove vibration, thermal movements, and noise and allowing elastic alignments.

- They solve problems like shock, corrosion, abrasion, stresses, load stress in numerous applications.

Besides, they also fix issues like vibration, pressure pulsation, and movement in the piping system.

- They protect against pollutants, such as humidity, dirt, toxins, and UV rays, present in manufacturing or any environment.

They also protect against grease, acids, bleaches, water, spatter, and pressure.

- Rubber Bellows acts as a shield for moving parts. They prevent dust and debris from entering and extending the service life and minimize the risk of interruption.

- They protect workers and others from injuries due to accidental contact with moving parts.

- Besides providing a shield to moving machine parts, they also act as cover for some applications.

What Are Different Profile/Shapes Of Rubber Bellows?

![]()

Following are the prominent shapes/profiles of rubber bellows:

- Round

- Oval

- Rectangular

- Tapered

Besides, BaiweSilicone can also design rubber bellows in customized shape/profile according to your application needs.

What Is The Average Life Span Of A Rubber Bellow?

The high-quality rubber bellow manufactured by reliable manufacturers like BaiweSilicone can last up to 1,000,000 cycles of travel.

What To Consider While Designing Rubber Bellow?

Designing a rubber bellow is not an easy task.

It would be best if you considered the following factors when designing your own:

Wall thickness, angle of convolute on bottom of the cavity, and deepest point for each curve to meet up with another at top.

If they are too far apart, it will cause unnecessary wear from repeated contact.

Also, take care that there aren’t any sharp edges that could tear or cut through this delicate material during the molding process.

Please ensure all undercuts have been removed so costly tool design costs won’t climb unexpectedly high due to their absence!

You may also consider:

- Required Direction of Travel: Whether it be a straight line motion or articulating motion

- The length needed for Travel: It is the large or small delta between peak and valley of convolutes.

- Interface between two Parts: It is the interface between two rubber bellows ends and mating parts.

- Outside Constraints: It is the envelope of Rubber Bellow’s working space.

- Working Environment: Select the suitable material according to the working environment, considering the temperature, pollutants like grease, oil, humidity, etc.

![]()

What To Consider When Choosing Custom Rubber Bellow?

When choosing a custom rubber bellow, you must first consider the direction in which it should expand or contract.

Next, determine its length of travel and then choose between different locking systems that will hold your equipment securely in place while allowing for fast transitions back-and-forth throughout each day’s use at work!

The right kind of material is essential according to how many cycles are expected per day as well as media inside said device.

These factors also go hand-in-hand with selecting what type would best serve this need.