Custom Rubber Gasket Factory

Baiwe has a complete production line for producing the best quality custom rubber gasket. We also have expert engineers and a professional R&D team. Thus, you can assure that Baiwe has the full capabilities to provide for your needs. Our expertise and high knowledge about the industry also guarantee you the highest quality and superior performance custom rubber seals . Choose Baiwe as your trusted custom rubber gasket supplier. Would you mind sending us your requirements?

We manufacture Custom Made HNBR Rubber Gasket made from Silicone, Neoprene, EPDM, and other high-quality rubber materials.

Biawe specializes in manufacturing all kinds of Custom Rubber Composite Gasket. We manufacture these products using high-quality rubber materials.

We offer Custom Rubber Gasket for Hurrier with waterproof features. It provides good sealing performance for a long-lasting application.

Our premier molding and cutting processes allow us to manufacture Custom Die Cut Rubber Flat Face Flange Gasket with a high-quality and customized logo.

Biawe manufactures Factory Price Custom Rubber Washer that features ozone resistance, weather resistance, waterproof, and wearable.

We offer ISO9001 Certified Custom Silicone Rubber Gasket that features chemical resistance. These are suitable for electrical, office machines, aerospace, and other applications.

Our Weather Windshield Rubber Rear Gasket features high-temperature resistance. These are made from EPDM rubber materials to ensure durability.

Biawe offers Silicone Flange Rubber Gasket with different colors like orange, blue, white, and more. It is suitable for auto parts applications.

We manufacture T Shape Rubber Gasket Seal using EPDM material to ensure tough environment resistance. It features accurate dims and a smooth surface.

You can purchase Custom Rubber Extrusion Gasket made from NBR, Silicone, Neoprene, and more. The colors and sizes of our Custom Rubber Extrusion Gasket can be customized.

We offer custom-made Molded Rubber Gasket Seal based on your drawings. We supply Molded Rubber Gasket seals made from EPDM, Silicone, NBR, and more.

Biawe offers a Customized Round Flat Rubber Gasket with skid-proof properties. It comes in customizable colors and sizes.

Baiwe: Your Premier Custom Rubber Gasket Manufacturer in China

Baiwe is a well-known rubber gasket manufacturer in China. We serve customers with the highest quality, excellent services, and great deals. Thousands of customers trusted Baiwe as their no.1 supplier of custom seals and gaskets because of our high experience.

Our reliable and robust commitment to quality will provide excellent solutions to your custom rubber gasket needs. Thus, giving you 100% satisfaction. Please send us your inquiries today!

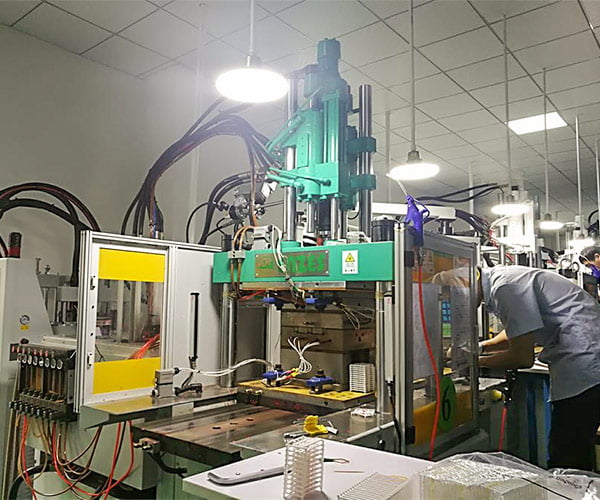

- Manufacturing

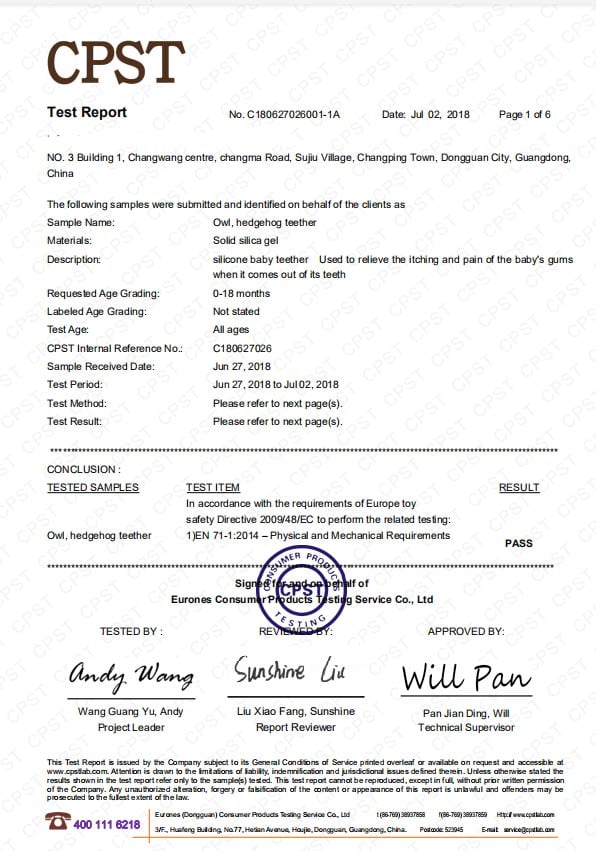

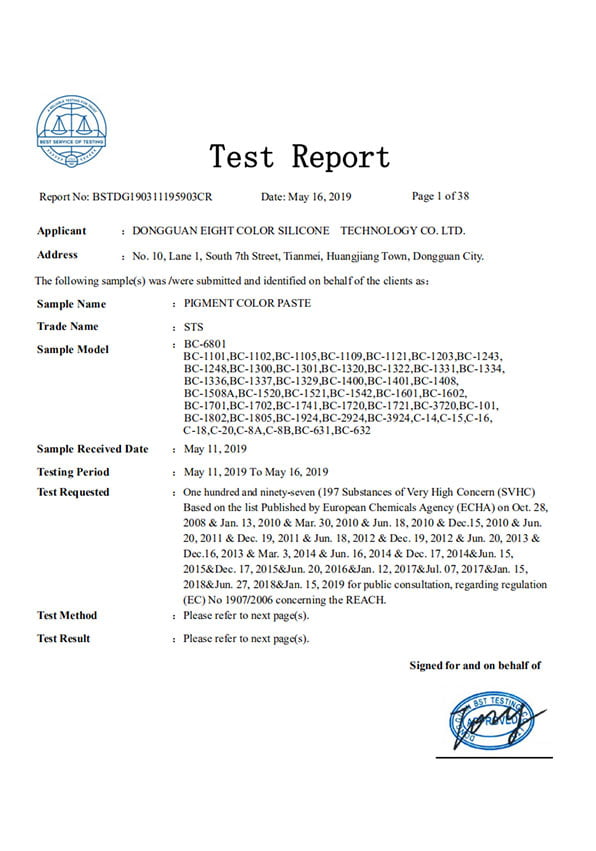

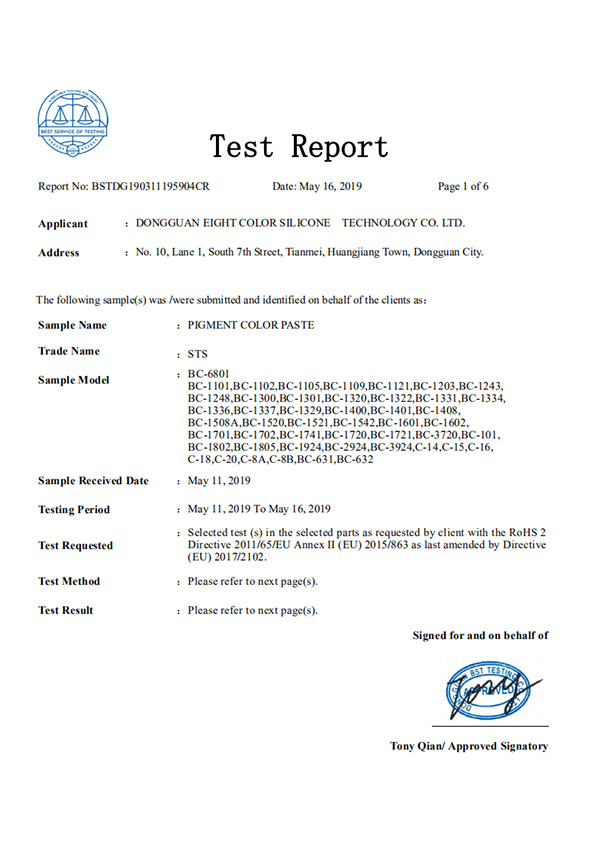

- Certifications

- Top Quality Control

Your Trusted Custom Rubber Gasket Supplier in China

Do you need a molded rubber seals for your business or project? Baiwe is your perfect choice! We can provide you a one-stop solution to your needs. With our over 15 years of experience, you can guarantee the best quality products and unmatched services.

We are well-equipped with advanced technology and complete production lines. Our state-of-the-art equipment allows us to manufacture special custom rubber gaskets. We also have highly experienced and knowledgeable engineers to design your orders.

Baiwe custom rubber gaskets offer many advantages. Our custom rubber gaskets can be three-dimensional. These products also feature tighter dimensional tolerances, no splices, and unique engraving for your logos and brand.

We offer customized rubber gaskets to meet the particular needs of your industry and business. Just contact us for your specifications. Here in Baiwe, we can help you in finding the right custom rubber gasket.

We design custom made rubber seals for making a tight seal between two components. Our engineers use a diverse range of rubber materials such as Neoprene, SBR, Silicone, Polyurethane, FDA Approved rubber, conductive rubber, natural rubber, and more.

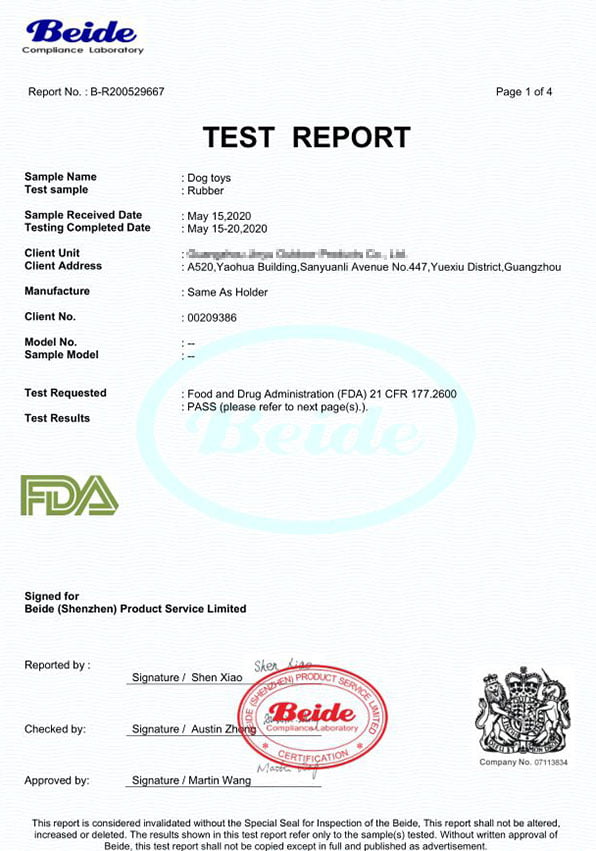

Baiwe also uses excellent production options to meet the most challenging sealing applications.Custom made rubber gaskets is available to meet your high performance and specific applications. These products also have certifications from REACH, RoHS, CE, and more standards.

Choose Baiwe as your trusted custom rubber gasket supplier for your business. We serve customers with the highest quality, excellent services, and great deals. You can also guarantee fast-lead time, low MOQ, fast delivery, and superior after-sales services.

Baiwe can give you 100% customer satisfaction. Here in Biawe, you can ensure the best purchasing experience if you buy a custom epdm gaskets, custom viton seals, and custom neoprene gaskets at Baiwe. Our professional sales team will provide 24/7 assistance to your needs and inquiries.

Enquire now for your next custom rubber gasket orders!

Rubber Gasket – Ultimate FAQs Guide

Thinking of buying a batch of rubber gaskets for your application? Need help in selecting the material for the gasket?

Therefore, we have crafted a guide to provide you with all the essential information related to rubber gaskets.

In the end, you will get in-depth knowledge about rubber gaskets and how to choose the right one for you.

Let’s start.

1. What’s Is Rubber Gasket?

2. What Are The Industrial Applications Of Silicon Gasket?

3. What Are The Advantages Of Rubber Gasket?

4. How Long Will Rubber Gasket Last?

5. How Are Rubber Gaskets Made?

6. What Are The Different Materials Used For Rubber Gaskets?

7. What Are The Most Used Rubber Gasket Cutting Methods?

8. What Is The Difference Between Custom Die Cut And Flash Cut Rubber Gaskets?

9. What Is Gasket Rubber Made Of?

10. How Does A Rubber Gasket Work?

11. When Would You Use A Rubber Gasket?

12. How To Choose The Best Rubber Gasket Manufacturer From China?

13. Do Chinese Manufacturers Produce Good Quality Rubber Gasket?

14. How Much It Take To Deliver A Batch Of Rubber Gasket To My Country?

15. How Much Does Rubber Gasket Cost?

16. Do Rubber Gaskets Need Sealant?

17. Does Rubber Make A Good Gasket?

18. Can I Get Customized Size Rubber Gaskets?

What is Rubber Gasket?

A rubber gasket is a mechanical seal used to prevent leakage of liquids and gases from various appliances.

Consequently, it can also be used as a barrier between two chemicals or metals to keep them separated from each other.

Technically, these rubber gaskets are customized according to the requirements and needs of the appliances.

There are hardly any two applications that might use the rubber gasket’s same design, shape, and size.

Usually, these mechanical seals help protect gadgets from dust and moisture to ensure perfect results.

For instance, camera lenses require mechanical sealant for protection as well as stay focused and get clear images every time.

Typically, the rubber gaskets are shaped and cut into desired sizes from large rubber sheets.

According to the application or industrial requirements, the engineers choose the rubber type that suits the most in a specific scenario.

The material selected for the rubber gasket must have tolerance of the surroundings it has to be kept.

Conditions such as tensile strength, compound percentages, temperature exposure, and hardness play a vital role in rubber material selection.

![]()

What are The Industrial Applications of Silicon Gasket?

The industrial application of silicon gasket is widely spread all over the place due to their versatile nature and resistant properties under harsh conditions.

Technically, these silicon gasket formulations are available to fit in many applications at budget-friendly rates.

Some of the significant applications are discussed below.

1. Aerospace Industries

The silicon rubber gasket’s resistance against elevated temperatures, UV rays, and ozone makes them an ideal material for airplanes and space and air-bound equipment.

From engine gaskets to ventilation ducts, insulating doors, windows, instrumental sealings, and thermal insulation, silicon gaskets is helpful everywhere.

2. Transportation Industries

Silicon rubber gaskets are capable of tolerating environmental stress with their solid and robust nature.

To that end, they are widely used in buses, trains, personal, industrial, and commercial vehicles, and high-power machinery.

3. Other Commercial Applications

Despite other industries, silicone gaskets are used in construction industries for sealing HVAC doors and systems.

Furthermore, these sealants are used in food industries for food processing machines and oven sealings.

What are the Advantages of Rubber Gaskets?

The advantages of rubber gaskets are many due to their long-lasting and resistant characteristics.

Here are some of the beneficial aspects of rubber gaskets.

1. Physical Characteristics

Rubber gaskets possess high electrical resistance, water resistance, and high electrical conductivity, making them superior to others.

Moreover, these rubber gaskets are corrosion-resistant and flexible enough to revert to their initial size and shape.

2. Color Availability

The customization of rubber gaskets into various colors has made them beneficial for use in terms of safety aspects.

Fortunately, the colored rubber gaskets can be used commercially for aesthetic appeal or indication purposes.

3. Safety Measures

Using rubber gaskets, industrial safety can be ensured for the long run because of its tolerance against tear and wear and demanding industrial environments.

Consequently, the rubber gaskets are manufactured to comply with medical standards and the FDA to ensure electrical and thermal conductivity and other specific properties.

4. Gradings

For commercial and industrial use, the rubber gaskets are available in different grades to meet the requirements.

Industries use hard and soft rubber gaskets according to the need for equipment.

![]()

How Long Will Rubber Gasket Last?

Rubber gasket lasts for about 3 to 5 years, depending on the use and handling of the substance.

However, it depends on the material quality and grading of the rubber gaskets, and sometimes it can last for 20 years.

The durability of the rubber gasket depends on the factors mentioned as follows.

1. Selection of Material

Seemingly, choosing a rubber gasket material might be a simple and obvious task, but every application can not be incorporated with the same type of rubber.

If the chemical compatibility of rubber and applications go wrong, or the material is exposed to unfavorable temperature conditions, it will reduce its life span.

2. Quality

Though everyone looks for cost-effective material, sometimes buying a cheap material leads to a low-quality product.

To that end, a material used in such a product might not be reliable and durable enough to last longer.

3. Installation

Correct installation of a rubber gasket plays a vital role in increasing the life span of the product.

Unfortunately, an inefficiently installed rubber gasket is more likely to crash prematurely while interrupting the workflow and replacement costs.

![]()

How are Rubber Gaskets Made?

Rubber gaskets are made with the complete sequences of cutting and punching procedures.

Some methods are stated as follows:

1. Punching

A rubber gasket is a traditional punching technique that involves bending a special steel strip into the desired shape.

Consequently, a hydraulic press comes into action from the top and forces the strip to pass through the cutter, yielding the desired shape.

Originally, this method was based on “Rule Forme” and was typically used for shoe manufacturing.

2. Water Jet

Water jet cutting is preferable over punching due to its quick yielding property, and it is because of its working dynamics.

Technically, a water jet of extreme high pressure is applied over the parent material and moves to cut in the desired shape.

Moreover, the process is applicable over hard, soft, cellular, and solid materials to produce infinite shapes in minimum time.

3. Laser Cutting

The working mechanism of laser cutting is similar to a water jet, but instead of a water stream, it’s the laser that cuts the workpiece.

Overall, it is a beneficial technique with flammability risk when exposed to potential wetting.

What are The Different Materials Used for Rubber Gaskets?

The different materials used for rubber gaskets are briefly described as follows:

1. Nitrile Rubber

Nitrile is a general rubber, purposely used for suitable temperatures ranging from -65 to 300 degrees F with efficient wear-resistant properties and can not crack easily.

2. Ethylene Propylene

Such materials are suitable for hydraulic fluids that are dangerous and corrosive when in contact with human skin.

Due to its high resistance against corrosive properties, it is well-suited for applications related to contact with other liquids.

3. Polyurethane

It is another type of rubber used under low temperatures and has worse resistance under elevated temperatures.

Typically, it is used in cold climates. Even in chilling winter, it won’t get brittle or crack.

4. Silicon

Silicon is the most common rubber gasket used at high temperatures, but it is not a reliable option for higher movements and tearing applications.

What are the Most Used Rubber Gasket Cutting Methods?

The most used rubber gasket cutting methods are discussed below.

1. Hand Cutting

Traditionally, the hand-cutting method is used for less complicated jobs with highly experienced workers and plenty of friendly tools.

2. Die Cutting

Die-cutting is a customized method to punch out the desired shape from the parent material.

Primarily, the die is manufactured based on the drawings and single-dimensional, which is then sent for the gasket cutting.

Unfortunately, the process is restricted to use the specific thickness of the materials for cutting.

3. Molded

Customized molds are manufactured to make rubber gaskets. Usually, this method is best for the high-volume production of unique shapes.

4. Water Jet Cutting

For the precise and quick rubber gasket cutting, the water jet cutting technique is used. It is an efficient method for neat cutting of thicker rubber materials.

![]()

What is the Difference Between Custom Die Cut and Flash Cut Rubber Gaskets?

The difference between custom die cut and flash cut rubber gaskets is die-cuts are relatively less costly for higher production of similar sizes.

While flash-cuts are a relatively expensive method of producing rubber gaskets.

Moreover, die-cut is a process of punching the desired shape from the parent material.

On the other hand, flash-cut is performed by an automated CNC machining procedure that cuts the stock material through a stationary cutting tool.

Furthermore, the dies utilized in manufacturing the die-cuts are highly customizable.

While flash cutting is a fast method and works efficiently with uncomplicated designs, rapid prototyping, and small volume production.

Die-cutting provides uniformity of creating identical forms; on the contrary, flash-cuts generate smooth edges.

What is Gasket Rubber Made of?

Gasket rubber is made of various chemicals depending on the conditions they are exposed to and the climate over there.

Some of the materials are mentioned below, along with their characteristics properties.

1. Chloroprene

Chloroprene (also known as Neoprene) is the first synthetic rubber used under harsh environmental conditions.

Due to its robust resistance against petroleum solvents and oil, it is highly versatile and efficient.

The reason behind its popularity is its durability against sunlight, ageing, and other cruel climatic ups and downs.

2. EPDM

Ethylene Propylene Diene Monomer (EPDM) is one of the most famous rubber materials available till now.

It possesses extreme protection against sunlight, anti-ageing property, and heat-resistant characteristics.

Due to its color stabilization property, it is a popular choice for many outdoor applications.

![]()

3. Fluorocarbon

Fluorocarbon (commercially known as Viton) is considered all-purpose rubber due to its higher temperature resistance range.

Commonly, it has diverse applications in many industries such as fluids, oil, gases, and specific acid types.

How Does A Rubber Gasket Works?

A rubber gasket works efficiently if the machinery and rubber material are in perfect combination with each other.

Usually, some of the rubber materials perform well with dry film lubricants, while others are more effective with wetter ones.

To enhance the efficiency and effectiveness of the rubber gaskets, they are coated with other powders or liquids to keep them healthy and lubricated.

Typically, the coating is applied over the rubber gasket by spraying, brushing, dipping, or rolling.

However, the gasket coating is applied before applying on the machinery, and sometimes even before cutting, all depends on the type of machinery on which it is used.

Subsequently, a tight-sealing is formed when a rubber gasket is compressed and displaced amongst two surfaces.

The resultant sealing maintains its shape and efficiency and prohibits vibration, temperature, movements, and the presence of liquids to interrupt.

Moreover, the rubber material used as a gasket depends on the surrounding conditions in which it is used, such as temperature, tensile strength, and durometer.

When Would You Use A Rubber Gasket?

You would use a rubber gasket in various residential and industrial applications, as they are necessary for maintaining an isolated atmosphere.

Consequently, they prohibit the loss and leakage of pressure at connecting points of two rigid materials, such as the joining of two metallic pipes.

Other than that, rubber gaskets have many other uses that are advantageous for your business including,

- Regardless of the absorption of pressure, the rubber seal remains unaffected and lasts longer than other comparative materials in the market.

- With the force exerted on the rubber gasket, its strength increases with the maintenance of quality standards.

- Rubber gaskets are malleable and can be cut or torn into any shape to fit your requirements.

- The material is entirely non-toxic, which means it doesn’t participate in the reaction; hence the purity is not compromised.

- Since rubber gaskets are odorless, they are beneficial for use in the pharma and food industries.

![]()

How to Choose The Best Rubber Gasket Manufacturer From China?

To choose the best rubber gasket manufacturer from China, it is important for you to first understand the requirements and applications you will use it in.

China is a popular rubber gasket supplier around the orb due to its premium quality and wallet-friendly manufacturings.

Among all, baiwesilicone is one of the best rubber gasket suppliers with 15 years of experience in the industry.

Moreover, they are committed to delivering excellent quality services at affordable rates and guarantees to efficiently meet your requirements.

With the constant efforts and hard work of skilled professionals, they are able to produce advanced products while boosting productivity.

Due to the combined productivity of three operational plants, Baiwesilicone can fulfill smaller and larger orders without any hassle.

All the orders and products are manufactured with equal preciseness and accuracy without compromising the quality and efficiency of the product.

Regardless of the quantity of your order, size, or shape, they ensure you get the right product every time.

Do Chinese Manufacturers Produce Good Quality Rubber Gaskets?

Chinese manufacturers produce good quality rubber gaskets worldwide with pre-eminent quality and cost-effective rates.

One of the leading Chinese manufacturers is Baiwesilicone. They are known for producing high-quality rubber gaskets and other silicone products with improved quality.

For years, the company’s skilled professionals have been keen on producing high precision and custom-made designs.

Moreover, they make sure you get the right quality at the right price, they maintain consistency of their working capabilities with three plants working simultaneously.

Furthermore, the technical team and staff members have been experienced in generating new techniques to fulfill your business needs for over seven years.

![]()

How Much it Takes to Deliver a Batch of Rubber Gaskets to My Country?

To deliver a batch of rubber gaskets to your country depends entirely on the quantity of the batch and the quality of the products you need.

In addition, it also depends on the distance of your country from China, as sometimes it requires prolonged sea and air routes to deliver a single batch.

Subsequently, the time required for delivering a batch to its owner is also affected by the weight of the order, i.e., the higher the weight, the higher the time will be.

Usually, the bulk orders of rubber gaskets are transported through air and sea routes as there are many legal procedures to follow that are time-consuming.

Ordering from Baiwesilicone will enable you to receive your order within a week or two, depending on whether the transportation requires a single route or double.

How Much Does Rubber Gasket Cost?

Rubber gasket costs vary according to the size, type, and properties that make them distinguishable from one another.

Usually, an extruding silicone rubber gasket price ranges from $1.00 to $1.29 per meter, while universal auto parts copper and rubber gasket prices are from $0.065 to $0.075 per piece.

A flat rubber gasket made up of EPDM costs $0.05 to $0.5 per piece. On the other hand, a household EPDM rubber gasket costs $0.1 to $2.0 per piece.

Consequently, there are some expensive rubber gaskets for industrial uses, such as a heat exchanger rubber gasket with a price from $5.0 to $10,000 per set.

Similarly, a flat rubber gasket made of silica costs $0.5 to $1.0 per piece, while a non-sterile material rubber gasket costs $0.0025 to $0.154 per piece.

Besides, prices are from $0.1 to $0.2 per piece for a customized compression rubber gasket, and a heat-resistant rubber gasket will cost around $13-$20 per kg.

Do Rubber Gaskets Need Sealant?

Rubber gaskets need sealants to continue functioning properly and provide extra insulating properties for longer periods.

Similarly, gasket sealant is used to hold the gasket once it is appropriately fitted. They protect them from slippage or failures.

Moreover, if the gasket is properly fitted with the sealant, it will provide extra protection of your machinery against debris and leakages.

Besides, some gaskets are already fitted with the sealant and don’t require an extra sealant to protect your machines.

Not to mention, gasket coatings and gasket sealants are used for different purposes. Coatings are used to secure the gasket seal from debris.

On the contrary, gasket sealants are required to seal the gasket itself to prohibit leakage and malfunctioning.

While some rubber gaskets don’t require sealants, they are still a better option for fitting into the applications.

Commonly, automotive industries use gasket sealants and gasket solids when they repair the old parts, making materials robust and resistant to harsh conditions.

Does Rubber Make A Good Gasket?

Rubber makes a good gasket due to its high flexibility, resistance, and non-reactive nature towards other chemicals.

The following are the examples of rubber gaskets that are frequently used in the industries:

1. Natural Synthetic Rubber

Natural rubber is an all-rounder with great multi-purpose properties. Though, it shouldn’t be used in fuels, oils, and other solvents.

Generally, natural synthetic rubber is used in water pumps, fitting pipes while adding vibrant and shock resistance qualities.

2. Cork

Due to its high flexibility, resistance characteristics, and compressibility, cork is widely used for rubber gasket manufacturings.

Technically, it is a renewable and sustainable material obtained from the bark of an oak tree.

Typically, it is used in fuel and oil pumps and areas around an electrical gear to increase efficiency.

3. Compressed Non-Asbestos

Initially, asbestos was discovered to be a dangerous substance, while compressed non-asbestos is a combination of high strength and other resistance properties.

These kinds of rubber gaskets are used in hard-to-seal applications at home to sustain high temperatures and steam.

4. Neoprene Sponge

A neoprene sponge is a rubber gasket that can be used in open and closed forms with repellence against debris and moisture.

Practically, they are suitable for use in fuel settings and near oil and other chemicals.

The cellular nature of the rubber gasket enhances its insulation, absorption, and compressive qualities.

Can I Get Customized Size Rubber Gaskets?

Get customized size rubber gaskets from trusted suppliers such as Baiwesilicone, a leading rubber gasket manufacturer in China.

For the past 15 years of experience, they are fulfilling the needs and demands of their consumers with premium quality customized products.

With the help of three working plants, they can produce any custom design without delay.

Moreover, they are committed to obtaining the best designs with high-temperature resistance, tensile strength, and durability.

The company’s skilled team ensures highly precise products, whether they are complex designs or simpler ones.

No matter how packed the work line is, strict quality checks are maintained to deliver the product of your choice.

![]()